Modern water supply systems are designed to provide uninterrupted water supply to the consumer, and it must be supplied from a tap under a certain pressure. This is ensured by special automation units consisting of a hydraulic accumulator and a water pressure switch.

Content:

- Types, their advantages and disadvantages ↓

- DIY installation and configuration ↓

- Device ↓

- The principle of operation and scope ↓

- Specifications ↓

- Cost and Manufacturers ↓

A hydraulic accumulator is a reservoir (membrane tank) in which a pear-shaped or rigidly fixed flexible membrane is located. Both that and another membrane divide the tank into two chambers: water and air, in which there is compressed air.

The membrane tank is used to create excess pressure in the water supply network and compensate for possible hydraulic shocks. In addition, it provides the necessary supply of fluid.

Under the action of a pump (supercharger), water enters the water chamber. At the same time, its volume increases, respectively reducing the volume of the air chamber and increasing the pressure of the compressed air inside it.

At a certain pressure, the pump switches off. When the consumer opens the faucet, water flows out of the reservoir (hydraulic tank) with a certain pressure, which is created by compressed air acting on the membrane.

Over time, the pressure gradually decreases to a critical value, after which a supercharger is turned on, which pumps the required amount of liquid into the tank. This process is repeated cyclically, and it is the water pressure switch that ensures the operability of the entire system without outside interference.

Types, their advantages and disadvantages

The industry produces several types of water pressure switches for pumps.

Among them are distinguished:

- mechanical;

- electronic;

Electronic devices operate more reliably and more accurately than mechanical ones. At the same time, they provide a more precise adjustment of the range of thresholds. In addition, they are all equipped with a flow sensor that blocks the pump in the event of lack of water in the system (“dry running”).

There are also mechanical devices equipped with dry run protection systems. However, in systems with such devices, after the appearance of water, the pump must be started manually, and electronic ones turn it on automatically. To do this, they provide a test mode for fluid movement (the pump is regularly turned on for 15 seconds and the sensor monitors the fluid movement).

In addition, many electronic components are equipped with a built-in hydraulic accumulator with a capacity of up to 0.4 lwhich protects the pump from water hammer at the moment of its inclusion / switching off.

Another drawback of mechanical relays is the rather complicated adjustment of the thresholds, which requires disassembly and the use of wrenches. To configure the electronic does not even need a screwdriver.

The only advantage of mechanical relays over electronic relays is their cost. The difference in price can reach several thousand rubles.

DIY installation and configuration

Installing a relay for a water pump is not difficult, but it has a number of features:

- Experts advise installing the relay directly near the accumulator. It is there that pressure surges are leveled when the pump is turned on and off.

- Some models have environmental restrictions. They must be installed in heated rooms.

-

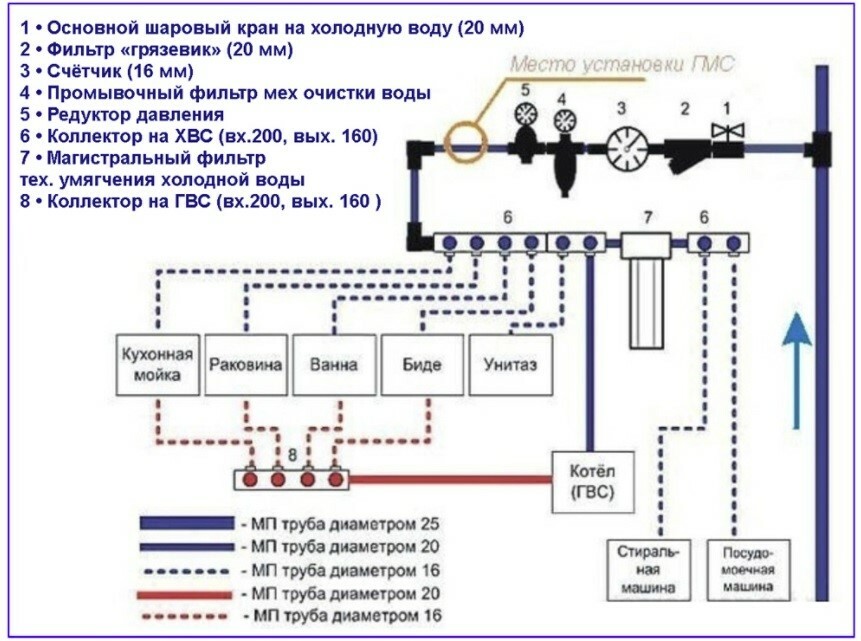

When connecting the device to the water supply system, in general, it is advisable to install before it:

- inlet valve;

- filters for rough and fine water purification;

- check valve;

- drain into the sewer;

- Almost all modern pumps have integrated water filters and check valve. In addition, they are equipped with special fittings for connecting a pressure switch. Therefore, if the relay is manufactured in a waterproof housing, it can be installed with the pump directly in the well.

- In order to reduce the wear of the elastic membrane, it is necessary that the pressure of water in the water supply system is 0.2 atm. was greater than the pressure of compressed air in the air chamber of the membrane tank.

-

Having finished connecting the device to the water supply system, proceed to the electrical connection:

- First, an electrical network of 220 V. is connected. The wires must match the power of the relay.

- Then connect the pump to the corresponding contacts of the product.

- It is necessary to pay attention to the fact that the relay can be power (switches the power contacts to the pump) or by the manager (issues a signal to the control unit). After carrying out the above work, the system is ready to work.

If necessary, do-it-yourself relay settings can be done.

For this:

- The range of variation of the value is determined. water pressure (differential).

- Turn off the product from the electric network.

- Remove the top cover.

- Set the required threshold values using two special spring-loaded adjusting screws located under the cover. The value of the set values is controlled using a manometer. Wherein:

The adjustment of the upper threshold, at which the pump is turned off, is carried out using the adjusting screw indicated by the symbol “P”. To change the actuator threshold, it is necessary to turn the screw in the direction of the arrow, corresponding to the designations “+” and “-“.

The lower threshold of operation, at which the pump will automatically turn on, is adjusted by rotating the second adjusting screw with the “5P” symbol in the direction of the “+” and “-“ designations;

Device

The device controls the amount of fluid pressure in the water supply network and maintains it at a given level. The smooth operation of the entire system as a whole, as well as its individual elements, depends on the quality of its work.

The relay in general is a device (unit) with special springs installed inside, with which the values of the minimum and maximum threshold and two pairs of contacts used to connect the electrical network and pump.

The plumbing system is connected to it through a threaded hole, the diameter of which is 1/4 inch. The water part of the block is separated from the mechanical elastic diaphragm. The fluid presses on the diaphragm, which acts on the respective springs.

One of the springs - the minimum pressure spring - counteracts fluid pressure. The stronger it is compressed, the greater the pressure of water is necessary for the relay to operate.

The second spring - the pressure differential spring - sets the range of variation of the fluid pressure between the boundaries of the relay. The stronger the spring is compressed, the greater the difference between the upper and lower threshold.

The principle of operation and scope

The operation of the device is ensured by the fact that the movable springs installed in the device’s body constantly monitor the water pressure in the system, if necessary turning the blower on or off.

Wherein:

- When a potential consumer opens a tap, then water comes to him from the hydraulic tank. The necessary pressure is provided by the pressure of the compressed air in its air chamber.

- As the amount of water in the tank decreases, her pressure gradually drops. When the minimum value is reached, the electrical contacts of the relay close, the pump turns on and supplies water to consumers directly, bypassing the membrane tank.

- When the consumer closes the tap, the supercharger pumps water for some time, again filling the water chamber of the tank. The pressure in the tank rises and reaches the maximum permissible value. At this moment, the relay contacts open and the pump turns off.

Water pressure switches are used in various water supply systems.

They serve to automate the operation of the water pump and in general provide:

- Automatic circuit recharge water supply.

- Water level monitoring in tanks (automatic emptying or tank filling).

- Maintenance of the set value of working pressure in membrane tanks of water supply systems.

- Water blower protection from the “dry run”.

- Other tasks, in cases where load control is required in a given pressure range in water supply systems.

Specifications

Existing models are available already adjusted in accordance with current standards. These settings are optimal and, as a rule, do not require changes.

Existing models are available already adjusted in accordance with current standards. These settings are optimal and, as a rule, do not require changes.

Most often, relays can maintain the working pressure of water in the range of:

- 1.4 to 2.8 bar (factory setting);

- 1.0 to 5.0 bar (manual installation);

In this case, the difference between the lower and upper threshold (differential) is from 1.0 to 2.5 bar.

In addition, all products have the following technical characteristics:

- Supply voltage, B - 220.

- Amperage, And no more - 12.

- Permissible water temperature, degrees Celsius - from +5 to +35.

- Maximum ambient temperature, degrees Celsius: +45.

- Criterias of choice.

Choosing the right product is not an easy task.

To do this, the potential buyer must imagine:

- Wednesdayin which the device will work.

- Required setting range differential.

- A set of additional features.

It is also necessary to pay attention to:

- Availability of installation.

- The presence of waterproofing.

- Correspondence of power of the pump motor contact groups.

- Possibility of independent adjustment parameters.

Cost and Manufacturers

The cost of the relay is in a fairly wide price range and is determined depending on:

- Device type (mechanical or electronic).

- Brand of the manufacturer.

- The presence of additional features.

So, the cost of mechanical relays of various brands is:

- TM Grundfos (Germany) with a differential of 0.2 to 8 bar - 4500 rubles.

- TM Danfoss (Denmark) with a range of settings from 0.2 to 8 bar - 3000 rubles.

- TM Italtecnica (Italy) - 500 rubles (standard settings).

- TM Dzhileks (Russia) - 300 rubles (standard settings).

At the same time, the cost of electronic devices, depending on the manufacturer, is:

- DPS-15A (China) - 1417 rubles.

- Brio TANK (Italy) - 3625 rubles.