Ceiling plinth nothing but a special type of a particular element, installed only in a certain position where the ceiling of the docks to the wall. The installation procedure requires special attention, as well as some knowledge, so that the joints are the most reliable and accurate. Before you begin, you need to cut into the plinth itself to certain suitable size pieces. To learn how to quickly and safely make it, it will tell in this article.

Special docking technology

If we talk about current trends, they offer only two solutions to this problem.

- The inner angle is most often found in small amount to the 180 degrees, most often 90.

- Outside corner, most often found in a large value of over 180 degrees, but is most common in the corner 270.

In some cases, you can meet and completely non-standard options, which in any case can be considered as the correct understanding looks like the inner as well as outer corner. No matter what the process, the docking takes place on the right or the left side bar, which in turn dock correctly.

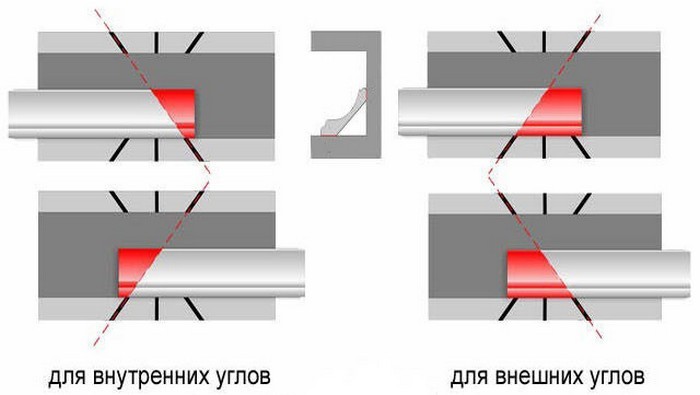

How to stitch type internal angles.

- Preliminary work begin with, how the restaurant to miter box and then pressing this part on the slit, which actually represents 45 degrees.

- The plinth must be cut off without fail only on the side with which it will be installed.

- Before you start interfacing process, you will need to attach the baseboard to the exact place where it will be installed, in order to make sure that he really is coming to this place. If there is any deviation, then you can always use an ordinary knife construction and clean up all the debris.

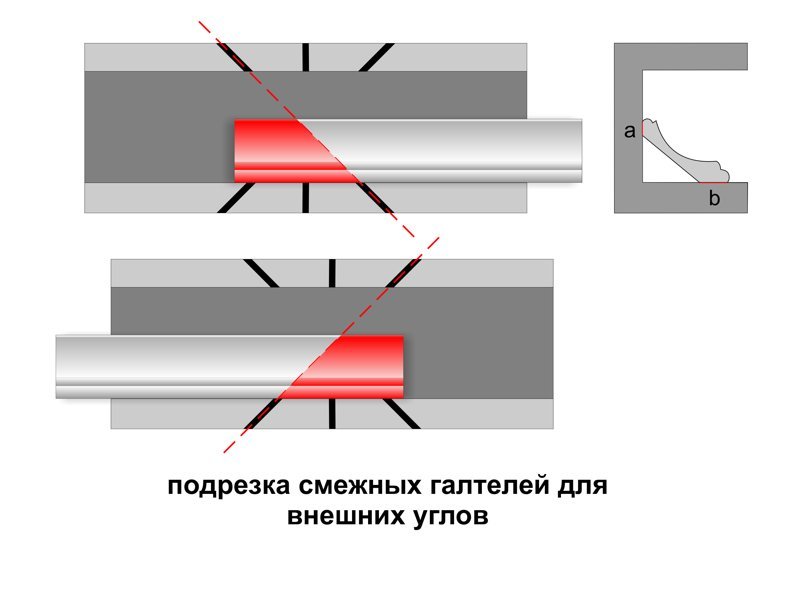

outer corners

What about external corners, they are carried out by radically different principle than the previous version. First, you need to choose the right type of starting point, then you have a plinth exactly where it will be cutting process, after that begins the final cutting products.

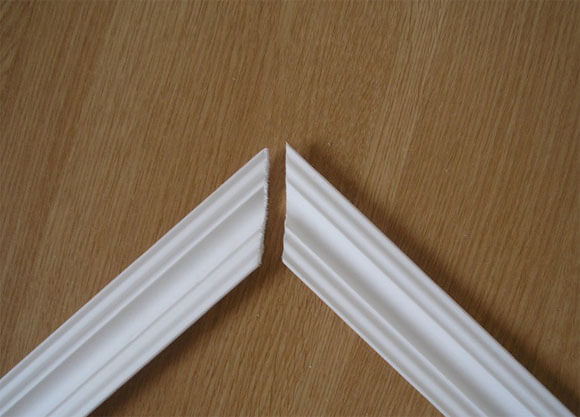

Already finished product must be set to the desired location and press. In that case, if slightly exceeded the size, you need to cut at lev marking 45 degrees.

What about non-standard angles, their matchmaking is done by cutting small pieces, which are selected under the bending angle.