Common modern materials are polymers. In many construction and manufacturing areas, they have replaced steel and cast iron products. A striking example is polymer pipes for water supply. Today, they are found in almost every apartment, country house, commercial building and industrial facilities. The popularity of pipes is also associated with the ease of processing the polymer.

The content of the article:

-

General information

- Features of polymer products

- Varieties of material

- Manufacturers of polymer pipes in Russia

- Pipes for water supply

-

Varieties of labeling of PVC products

- Features of the installation of polymer pipes

- Features of welding

- Installation tips

General information

Polymeric materials include compositions of certain compositions that are obtained from oligomers, monomers and polymers with the addition of additional components. Due to this, they receive special properties.

Used as additives:

- fillers;

- stabilizers;

- plasticizers;

- dyes;

- lubricants;

- binding reagents.

That is why polymer products have different properties, some of them made it possible to use polymers in the manufacture of pipes for water supply.

Features of polymer products

The popularity of polymer products is associated with the unusual properties of the material. Plastic and durable polymer has many advantages:

- Wear resistance and long service life. Polymers practically do not react to humidity and temperature changes, therefore their service life is more than 50 years.

- Ecological cleanliness. The chemicals contained in the composition do not affect the environment. The surface of the pipes does not emit toxic components, therefore the composition of the medium in the system remains unchanged.

- High frost resistance. Many polymers can withstand up to 50 freeze and thaw cycles.

- Resistant to high humidity. Polymer pipes do not change their quality even after long-term operation under conditions of high humidity. Therefore, they are suitable for creating a water supply system.

- Reusability and good maintainability. The applied methods of connecting individual parts allow dismantling the water supply system with the subsequent use of all sections. The repair work takes a little time.

- Easy to care for and clean. The surface of the polymers is smooth and has no pores. Therefore, the contaminants are not absorbed into the material, and it does not take long to remove them.

- Wide range of applications. Pipes for the water supply system are made with different wall thicknesses and diameters.

The main disadvantages relate to the relatively low strength of the structure. According to this indicator, polymer products are inferior to steel or cast iron, which does not allow them to be used for the installation of a central high-pressure water supply system.

Varieties of material

There are several dozen varieties of polymers, but not all are suitable for making pipes. On sale there are:

- Polyvinyl chloride. This material comes at a low cost. Often used when installing open water supply networks. Individual elements can be connected into one system using welding or fittings (at low pressure), special glue. Not suitable for high temperature environments as heat reduces strength and increases elasticity. The exception is chlorinated polyvinyl chloride, which is resistant to high temperatures.

- Polypropylene. Such a polymer is common due to its low weight and high strength. Suitable for hot environments. The connection of individual elements is carried out by welding.

- Polyethylene. To create a water supply system, low-pressure polyethylene or cross-linked polyethylene is suitable. The peculiarity of this variant is its high flexibility and resistance to vibration.

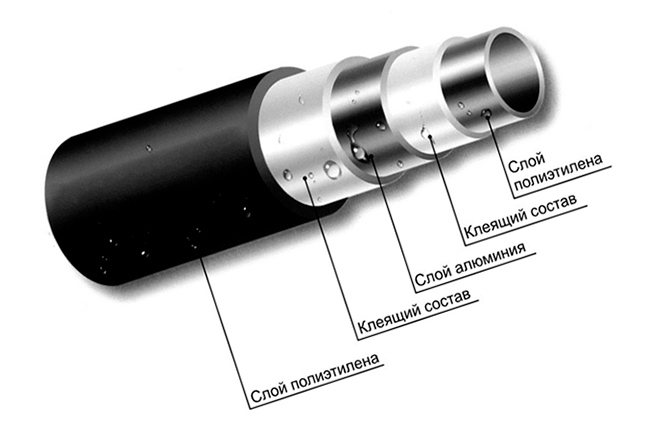

- Metal-plastic. This polymer is more expensive than others. Retains its shape when folded. Exposure to hot water with a temperature of up to 95 degrees Celsius is allowed.

The rest of the polymers are not used in the manufacture of pipes for water supply.

Polymer pipe device

Manufacturers of polymer pipes in Russia

For the production of polymer pipes, special equipment is required, which allows you to give the products the desired qualities. There are several large companies in Russia that supply similar products:

- Rupheim.

- TM Valfex.

- LLC NPO Polymer.

- Production company "Lammin".

- GC "SantechRegion".

- TM "H2O".

- The company "Kubanechnoplast" and others.

Many Russian companies are switching to foreign equipment. The ongoing modernization allows you to reduce costs and improve the quality of products.

Pipes for water supply

The choice of pipes is taken with due responsibility, since low-quality options lead to leaks and other problems. When choosing, it is taken into account:

- appointment;

- operating conditions for which the product is designed;

- water temperature;

- life time.

Preference should be given to polymer pipes with long-term performance that correspond to GOST R 52134-2003 *.

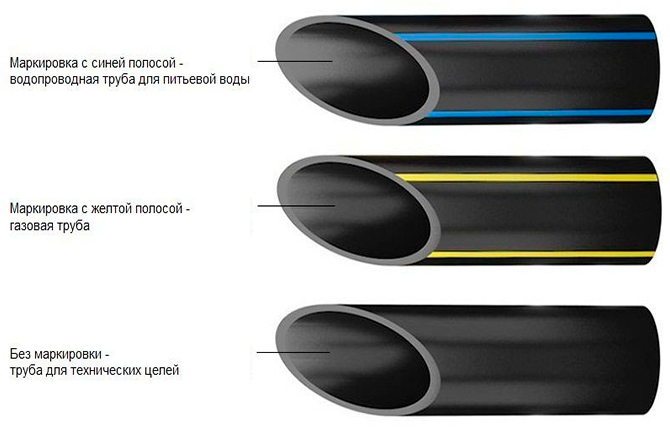

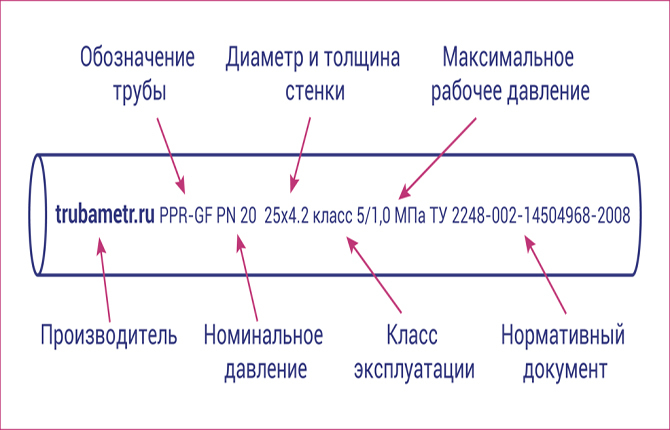

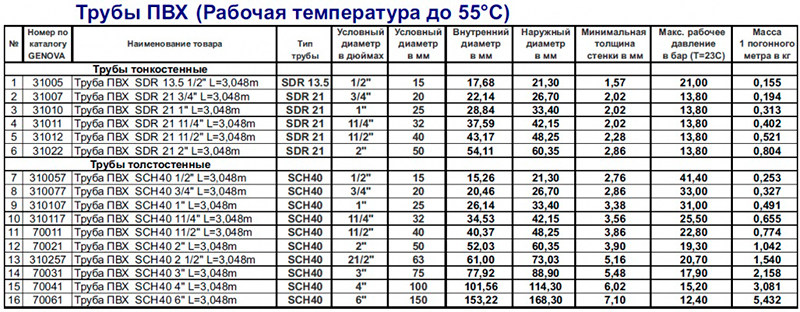

Varieties of labeling of PVC products

For the products in question, their own labeling standards have been introduced. Pipes made of the same material, but having different wall thicknesses, differ in properties.

The features of the marking carried out include:

- PN is the value of the maximum allowable working pressure at an ambient temperature of 20 degrees Celsius, at which water supply without repair will be carried out for 50 years;

- SDR is a value equal to the outside diameter divided by the wall thickness.

The designation "PN" is often followed by a number, for example, 25. It indicates the maximum pressure at which the pipe can be used. The marking sometimes indicates the outer and inner diameter of the product in millimeters.

Material designation is carried out using special markings. For the installation of the water supply system, pipes with the following designations are used:

- PPH is a homopolymer that is obtained using a small amount of additives. Products with this marking in most cases have a large diameter. Used to create an external water supply system.

- PPB is a complex type of polymer called a blockomer. It is characterized by an unusual molecular structure with high strength. Therefore, PPB is used to create critical areas in the water supply system operating in adverse conditions.

- PPR is a static copolymer with a crystalline arrangement of molecules. Due to this, the material can withstand strong and frequent changes in ambient temperature. The diameter of pipes made from this polymer is 16-110 mm.

- PPS is a polymer characterized by resistance to high temperatures and mechanical stress. Increased strength and wear resistance make it possible to use it for the installation of central water supply systems. The diameter of the pipes is 20-1200 mm.

Some manufacturers add their own markings by which you can find out about other characteristics of the product.

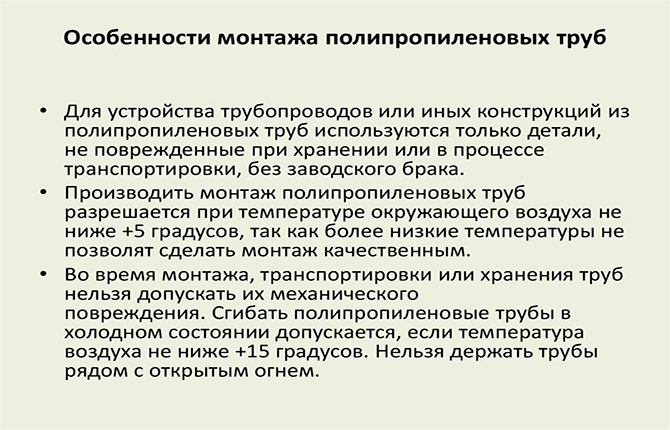

Features of the installation of polymer pipes

For the connection of individual polymer elements, special equipment and fittings are required. Despite the high workability of the material, a cutter is required to change the length of the sections.

For work you will need:

- construction tape;

- marker;

- angular ruler.

The installation process is divided into several stages:

- Cutting to size of individual pipe sections.

- The place of the cut is cleaned from burrs and other defects.

- A suitable fitting is selected.

- Installation of all elements is carried out with their fixation.

You can create a water supply system in a few hours. To increase the strength of the joints, a special soldering iron for polymer products.

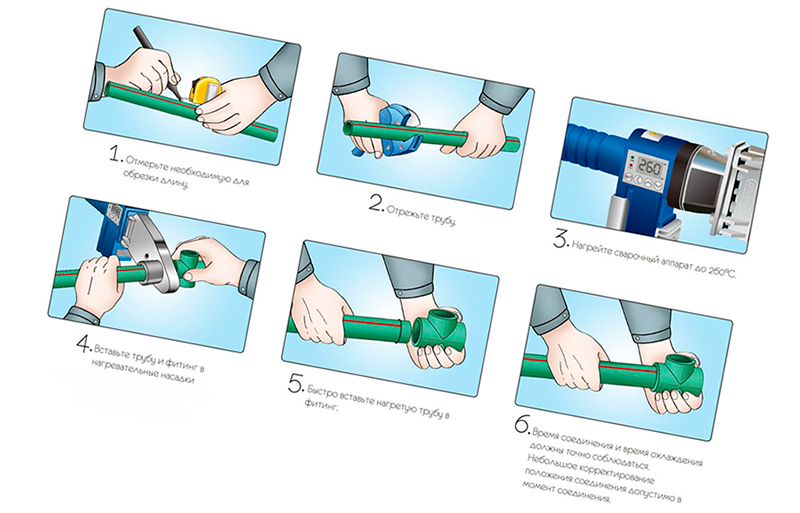

Features of welding

Welding works are carried out to improve the reliability of polymer pipe joints. To do this, you need a special soldering iron with nozzles. Due to the effect of high temperature at the joint, a strong seam is formed.

There are several welding technologies:

- electrofitting is a common tool that allows you to get a high-quality connection;

- in cold welding, the two parts are joined with a special glue.

Brazing pipes

When using a soldering iron, select the nozzle and set the correct heating temperature. For many polymers, the maximum is 260 degrees Celsius. At the time of welding, both parts are joined, come into contact with the heated nozzle. After removing the nozzle, the fitting is fixed. An important point - you cannot change the position of the two parts relative to the axis.

Installation tips

Installation work when using polymer pipes can be done independently. They are easy to fit and cut on the construction site. The material bends if necessary.

After cutting the polymer, it is necessary to process the resulting end surfaces with a knife. Small chips and other defects will prevent joint-to-joint installation, which will reduce the degree of pipeline sealing.

If welding of products of small diameter is carried out, their permeability is immediately checked. Incorrect nozzle selection or temperature can melt the interior.

Polymer pipes have become a popular building material over the past decade. They are suitable for creating cold and hot water systems. At the same time, the price of polymer is much lower when compared with cast iron and steel counterparts. In addition, the installation of the pipeline can be done independently.

Do you prefer polymer or cast iron pipes? Write in the comments. Share the article on social networks and save it to bookmarks.

See in the video which pipe is better than PPR, polyethylene or metal-plastic.