With the development of the chemical industry, many metal structures were replaced by their analogs made of polymers. During the construction of individual low-rise buildings, the priority is the installation of plastic ventilation ducts. Their technical qualities and technological advantages provide superiority over the previously used options.

An untrained person will say that plastic releases toxic substances into the air, therefore, it is harmful to health. To make sure that this is not at all the case, and modern polymer materials have European certificates of quality and safety, this article will help.

We will tell you about the specifics of the ventilation system made of polymer pipes. We will acquaint you with the assortment, give recommendations on the choice. Independent DIYers will find information on wiring options and connection methods with us.

The content of the article:

- Materials for the production of plastic pipes

- Assortment by standard sizes and cross-sectional shape

-

Ventilation device made of polymer pipes

- The use of thermal insulation shelters

- Design and preparatory work

- Calculation of the cross-section of air ducts

- Algorithm for calculating the frequency of air circulation

- Connecting fittings and equipment to be installed

-

Installation of a ventilation complex made of polymer pipes

- Layout of ventilation ducts in a low-rise building

- Methods for connecting plastic pipes

- Regulatory requirements for the laying of ventilation pipes

- Conclusions and useful video on the topic

Materials for the production of plastic pipes

The construction market offers ventilation pipes made of several types of polymeric materials.

The consumer is offered:

- Polyvinyl chloride (PVC) pipes can operate in a temperature range of -30O up to +70O Celsius. They are mainly used in household and residential construction for heated and cold rooms. PVC - non-flammable, thermoplastic material, melting point 165-200 degrees. Good dielectric. The inside has a smooth surface. Poorly tolerates frost, at a temperature of 15O below zero loses its properties.

- Fluoroplastic ventilation ducts (PTFE) have high temperature resistance, can withstand heating up to 260O Celsius. Air ducts are used to transport air mixtures with a high content of acidic and alkaline ingredients. Fluoroplastic is used in industry for the manufacture of high-strength ventilation networks.

- Air ducts made of polypropylene (PP) stand out at an affordable price, they resist well the aggressive components of the air environment: acids, alkalis.

- Polyethylene pipes (PE or LDPE, HDPE) they are lightweight, flexible, elastic, but poorly resist negative temperatures. The material is neutral and does not interact even with acids. Polyethylene does not emit harmful substances, it is considered absolutely harmless.

Polyethylene pipes are designed for a long service life. Internal smooth surfaces practically do not offer resistance to air currents moving along them.

European countries have recognized PP as a technically obsolete material. You can still buy polypropylene air ducts in the Russian retail network.

Polypropylene pipes are used in pipelines to move corrosive gases that cause metal corrosion

The purchase of products from this material in a residential building will be justified for use in utility rooms or with a lack of budgetary funds.

Assortment by standard sizes and cross-sectional shape

Most popular in residential construction PVC air ducts are available in two versions:

- round with cross-sectional diameters of 100 mm, 125 mm, 150 mm, 200 mm;

- rectangular with cross-sectional dimensions 55 × 110 mm, 60 × 122 mm, 60 × 204 mm.

The capacity of circular ventilation ducts increases with increasing diameter. The efficiency of a pipe with a diameter of 125 mm is 1.5 times higher than that of a pipe with a diameter of 100 mm, and a pipe with a diameter of 150 mm is three times higher than the "hundredth".

PVC pipes cannot be used to transport air with temperatures over 50 degrees Celsius. The duct diameter should not be less than the diameter of the duct outlet. Otherwise, the bandwidth of the channel is reduced.

A 100 mm circular duct operates at the same capacity as a 55 × 110 mm duct. A 125 mm round duct and a 60 × 204 mm rectangle are practically equivalent in terms of air throughput.

Round pipe 200 mm is produced without a wide range of fittings. An air duct with a rectangular cross-section of 90 × 220 mm corresponds to a round pipe with a diameter of 150 mm, but it is rarely used in practice due to its high cost.

Such remarkable characteristics as:

- the ability to absorb noise and heat;

- perfectly smooth surface allowing air to pass through the channel at high speed;

- no corrosion, which makes it possible to lay pipes in rooms with high humidity;

- indifference in relation to aggressive influences, ensuring long-term operation;

- walls, treated with an antistatic agent, preventing the accumulation of electric charges, dust settling inside the channel;

- sufficient strength and low weight;

- simple and straightforward process of assembling enlarged units and spatial systems;

- production of parts in accordance with GOST and TU with obtaining certificates for compliance with sanitary and hygienic requirements;

- relatively affordable price.

Among the disadvantages of PVC pipes are low fire resistance, fear of negative temperatures, the need for antistatic treatment.

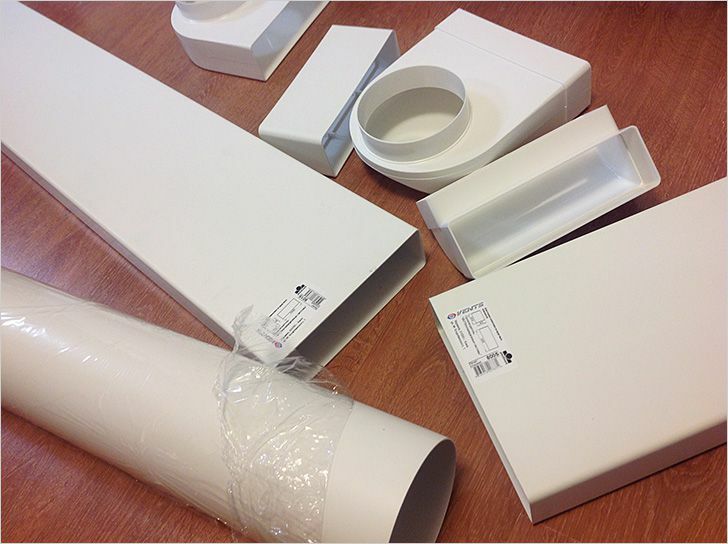

Rigid air ducts are made by casting and solidification in a molding formwork. Channel wall thickness is at least 3 mm. Pipes can be purchased at any supermarket or from manufacturers, the most famous of which are: ERA, VENTS, Eco-Trade

The white color of the plastic is in perfect harmony with the decoration elements of the rooms, often the air ducts are hidden behind drywall with subsequent finishing.

Low height polymer boxes helps to reduce the space between the floor slab and the false ceiling. Thus, to maintain an acceptable height of the room and its cubic capacity.

Ventilation device made of polymer pipes

Subject to certain rules, the installation of PVC air ducts is quick and easy. A significant role in this belongs to the methods of joining individual parts. A huge selection of fittings is offered: corners, elbows, tees, plugs. If one part fails, it is easy to dismantle and replace it with a new element.

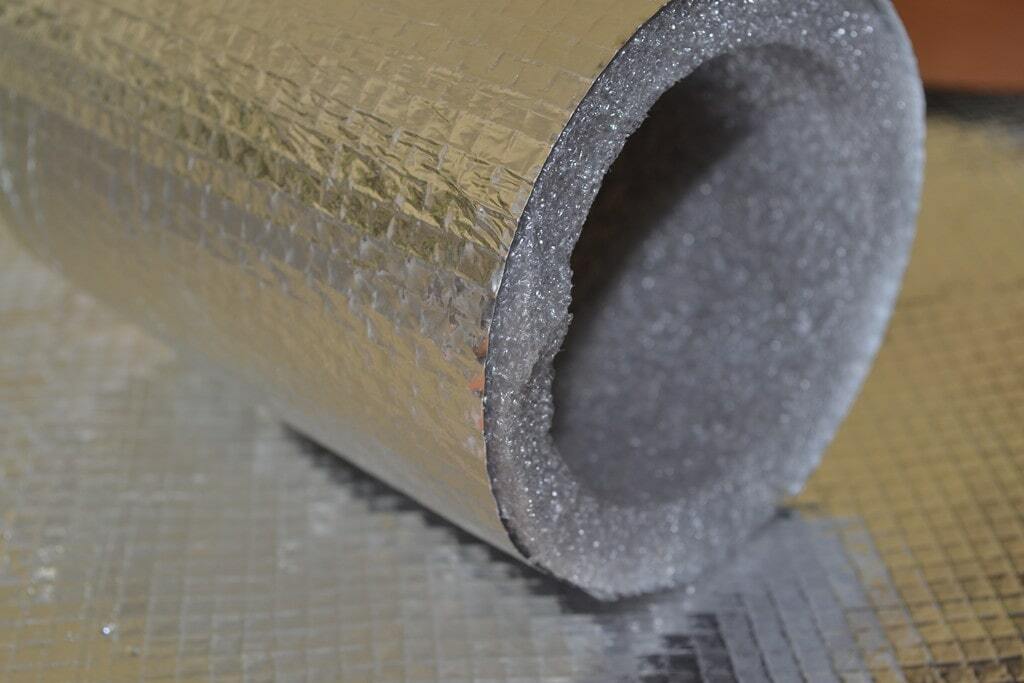

The use of thermal insulation shelters

In unheated rooms, polymer channels are wrapped with heat-insulating materials. Otherwise, the pipes will be covered with frost in winter.

Used as insulation:

- foamed polyethylene, on one side covered with foil, on the other, coated with adhesive;

- a layer of rubber with the same coatings, this material is much more expensive than the first.

Before thermal insulation, the surface of the duct is cleaned of dust deposits and dirt. Seams are sealed with a special foil tape.

Foamed polyethylene insulation is inert to harmful influences. In the trade network it is presented in a stitched and unstitched form. The first has no additional molecular bonds and is less strong than the second

The cross-linked polyethylene heat insulator is made using a special technology that creates linear and cross molecular bonds. The material is very durable, elastic, does not lose its shape after being squeezed.

The foam rubber insulation has a microporous structure. The material is resistant to aggressive environments, retains heat perfectly. Has a foil layer that prevents heat loss, provides sound insulation. Protects flammable materials from fire due to its high ignition temperature.

For thermal insulation of volumetric air ducts, especially when laying routes outdoors, mineral wool slabs are used.

Design and preparatory work

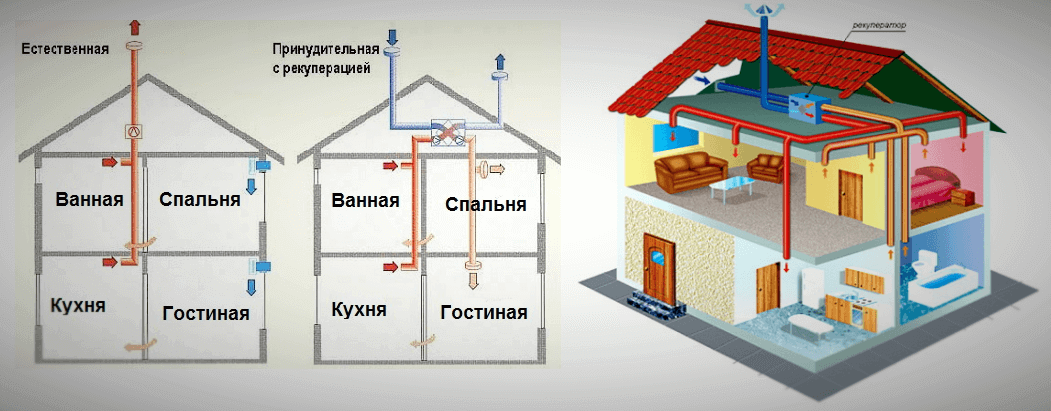

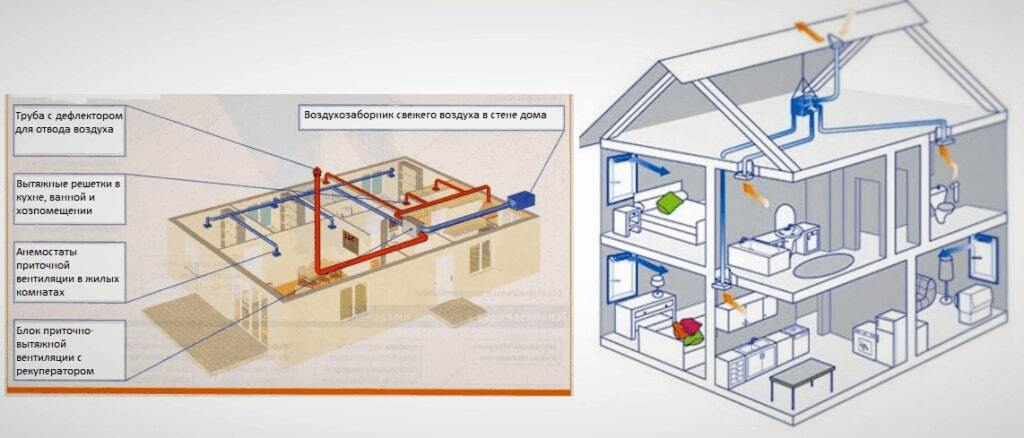

Before starting design work, you should decide on the choice of a ventilation system.

It is of three types:

- supply and exhaust with air circulation due to natural gravity;

- supply and exhaust with mechanical induction of the movement of air flows;

- combined using the first and second type.

Natural air circulation depends on weather conditions. In the hot season, when the temperature inside the house and outside is equalized, it is required to turn on the pulling force due to the installation of electric fans in the channels. There are devices on sale that are designed for installation in a polymer plastic ventilation system.

When creating natural ventilation, fans and electric motors are not installed in the system, which significantly reduces the cost of installation and operation of equipment. A mechanical ventilation unit installed in the attic distributes fresh air evenly throughout the house, preheating it in a recuperator due to the heat of the outgoing air stream

Installation is carried out according to a previously developed ventilation project. The complex structure of the ventilation complex will require an appeal to professional designers who will tell you how to assemble a plastic ventilation system.

For accurate calculating the area of air ducts and their location, you need to have a certain set of knowledge. Take into account the established standards and perform calculations according to a specific algorithm.

It is possible for a person who is able to independently study the basic norms and design rules to make working drawings of a simple ventilation unit on their own.

Calculation of the cross-section of air ducts

To calculate the parameters of the ventilation system elements, one should be guided by the instructions of SP 54.13330, SP 60.13330, SanPiN 2.1.2.2645.

To independently determine the size and number of air ducts, fans and their power, the easiest way is to calculate the parameters using the air flow rate per 1 sq. m. area of the house, equal to 3 cubic meters. m / hour. In this case, the frequency of air exchange and the number of people are not taken into account.

There are three ways of counting:

- by the number of complete air turnover in the room for 1 hour;

- on sanitary requirements;

- by the total area of the rooms.

The air exchange rate for living rooms is 1 time / hour.

Kitchen with a gas 4-burner hob - 90 m3/ hour plus additional 100 m3/час.

Kitchen with electric stove - 90 m3/час.

Bathroom, toilet - 25 m3/час.

Room with a solid fuel heating boiler - 1 + 100 m3/час.

Boiler room with a gas unit - 3 + air volume for fuel combustion.

Algorithm for calculating the frequency of air circulation

To determine the diameters of the air ducts, find the standard hourly air flow for each room and, in general, for the inflow and outflow in the system:

- The volume of air in each room will be equal to its cubic capacity. To determine it, the length of the room is multiplied by the width and height.

- The standard values of air turnover for each room are taken into account and the hourly air consumption is determined.

- The results obtained are rounded up and summed separately for air flow and air removal.

- Keeping the balance of air inflow and outflow is the basis of the calculation.

- The resulting total hourly air consumption is used to determine the size of the main supply and exhaust ducts.

- They are set by the required air speed - 3-4 m / s.

- According to the diagrams in the normative reference books, the required pipe diameter is found.

- According to special tables, you can also find a box of an equivalent section there.

Working drawings and a diagram will tell you how to assemble a plastic ventilation system in accordance with the projected capacity. They are performed independently according to the data of the calculation.

The drawings determine the total length of the ducts, the number of straight sections, turns, required tees, adapters and fasteners. According to the calculated data, fans, filters and check valves are purchased

Specific locations of ventilation ducts are marked, center lines are drawn, points of attachment of air ducts are marked. The presence of drawings provides accurate marking of the passage of ventilation ducts, punching holes in walls and ceilings.

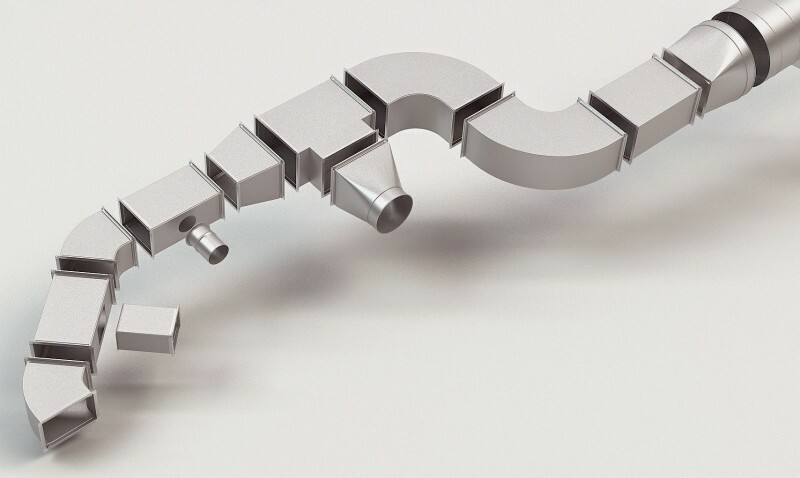

Connecting fittings and equipment to be installed

To connect rectilinear parts into a spatial branched network, typical fittings are used:

- check valves;

- tees - a fitting with three holes, connects two parts of the main channel, a side branch is connected to the third outlet;

- crosses - for connecting two side branches;

- adapters from a round pipe to a rectangular one, from one size to another;

- bends for turning the ventilation duct;

- couplings;

- plugs and grilles.

The check valve in the ventilation ducts controls the air movement in the desired direction. It does not give an opportunity for reverse thrust to appear. Design check valve is very simple: the blade opens when the air flow moves in the direction set by the project; when it moves back, it closes the channel passage.

A complete set of necessary fittings allows quick and easy assembly of ventilation sections. It is recommended to purchase fittings with a small margin - 10-15% of the total

Filters for cleaning the air from dust and small debris are installed on the supply air ducts. With a lack of natural flow of fresh air through the windows and vents in the walls of the building, they are mounted supply valves.

Due to the difference in pressure inside and outside the building, street air will enter the room in the gravity ventilation networks. However, its work can be interrupted in the summer, when the pressure outside the window and in the room is equalized. To create a stable ventilation system that does not depend on weather conditions, supply or exhaust fans are installed in the ventilation duct system.

For heating the supply air in the cold season, in the attic of the house, they are installed recuperators. The principle of their operation is to transfer the heat of the removed air flow to the newly supplied air volume.

The recuperator saves money on heating. The principle of operation of the device: the exhaust air passes through the heat exchanger and partially gives up its thermal energy to the incoming air stream. Parts made of materials with high heat capacity are used as heating elements

A separate exhaust duct is installed for the cooker hood. Ventilation grilles in the rooms are equipped with non-return valves. The technological process carried out by a team of professional installers is not much different from the installation of plastic ventilation with your own hands.

The procedure for creating a ventilation system for a private house outlined below can be considered a guide to action for those who like to do everything on their own.

Installation of a ventilation complex made of polymer pipes

At the preparatory stage, the entire assortment of parts is procured according to the design specification. For insurance, the stock of fittings and fasteners is increased by 10 percent.

You will need a simple set of tools:

- for cutting plastic pipes and boxes a hacksaw for metal or wood, to speed up work - a small saw "grinder";

- puncher for drilling holes in walls and ceilings;

- sandpaper, glue, sealant, mounting tape;

- tape measure, marker;

- screwdriver.

They begin work with the assembly of enlarged units, using the entire arsenal of fittings. The main element of the assembled modules and air ducts is a straight duct or pipe with standard dimensions. Round pipes and rectangular PVC boxes have lengths ranging from 0.35 to 2.5 meters.

For even cutting, an exact cutting line is drawn on the surface of the box or pipe. You can use a laser tool. Saw strictly along the marked line. After cutting, smooth ends without burrs and roughness remain.

A large section is applied to the wall or ceiling, the binding, the attachment points are specified and fixed in the design position.

When routing pipes, it should be borne in mind that each angle of rotation reduces the efficiency of the system. The shorter the total length of the air ducts, the higher their performance. For laying air ducts in a private house, it is better to use rectilinear parts 2.5 meters long so as not to make unnecessary connections.

Air velocity in circular ducts is higher than in rectangular ducts. But to save space, flat boxes are often used.

To insure against the resulting condensation, drainage holes are made in the pipes. To remove dew drops, the horizontal channels are given a slope of 0.01-0.015.

The cooker hood is connected to exhaust duct by means of an adapter from round to rectangular section. The connection point is sealed with silicone mastic.

The hood should be located close to the outlet of the exhaust duct, thereby reducing the loss in the rate of removal of kitchen fumes. The recommended diameter of the exhaust duct is 125 mm. The capacity of the exhaust unit is about 200-300 cubic meters per hour. The height of the hood from the surface of the electric stove - 65-75 cm, gas - 75-80 cm

To pass through the wall, the duct is placed in a sleeve. The channel outlets are covered with decorative grilles. The sagging of the duct should not exceed 50 mm.

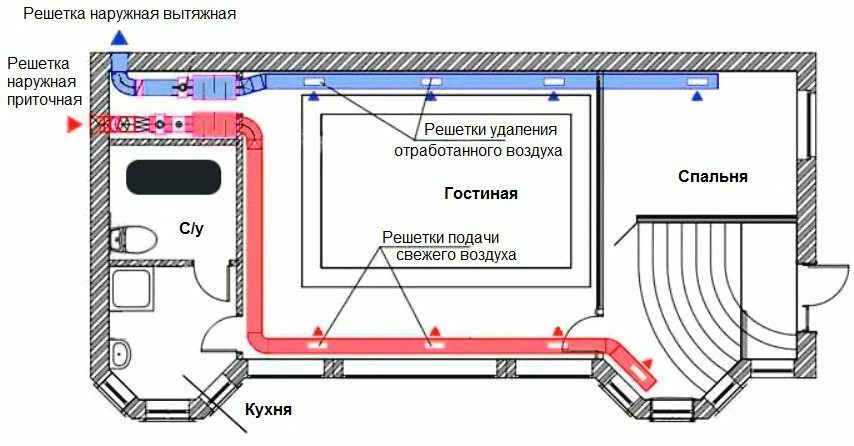

Layout of ventilation ducts in a low-rise building

Using the example of a typical residential building, you can learn how to assemble a PVC plastic ventilation system.

In a two-story cottage with a standard set of rooms, one vertical exhaust duct with tees is required to connect the side outlets to the living rooms. With this plastic duct, stuffy air from bedrooms and living room will be transported to the attic.

Nearby descends from the attic to the first floor of the same supply channel with the distribution of side branches along the zones of fresh air supply to replace the remote one.

For the kitchen, two air ducts are provided:

- a separate exhaust duct for the hood above the stove, going from the first floor to the attic;

- conventional exhaust duct.

Autonomous exhaust ducts are pulled into the bathrooms to remove vapors from the bathroom and air from the toilet.

The hood is connected to the ventilation duct through a tee and a check valve with an offset axis. When the hood is turned off, the valve is open, the air into the duct from the kitchen is removed past it. When the hood is on, the valve closes the inlet, kitchen vapors do not enter the premises

The assortment of plastic duct fittings includes round plastic holders for attaching pipes to a flat surface.

For boxes, rectangular mountings of appropriate sizes are provided.

Installation process:

- a hole is drilled in the wall or ceiling using a punch:

- with the help of dowels and self-tapping screws, the holders or brackets are fixed.

Plastic fasteners work like latches, wrapping tightly around the fastened element. As fixings to the ceiling, you can use metal plasterboard hangers.

On the air ducts running under the ceiling, tees and bends are also installed to supply or remove air from different zones of the residential building.

All ducts are led out to the attic and there are connected to the internal block of the system using flexible round ducts. Adapters for connecting attic round pipes are placed under the ceiling of the last floor.

It is recommended to seal all connections with silicone sealant to prevent air loss. If the boxes are closed by a false ceiling, all joints are additionally sealed with mounting tape. Suspended fasteners are screwed to the ceiling using self-tapping screws and dowels

Depending on the chosen ventilation method, one powerful device is placed in the attic, providing an exhaust hood and air flow throughout the house, or fans are placed in each duct.

In a cold attic, pipes must be insulated. The height of the removal of ventilation ducts relative to the ridge of the roof is determined as follows: the drawing is drawn from the ridge of the roof a horizontal straight line, from it up 10 degrees draw another Ray. He will be the claim height of the ventilation pipes. If the distance from the roof ridge to the ventilation pipe is less than 150 cm, it rises 50 cm above the roof ridge.

Silicone joint sealant is white and remains elastic when dry. For more reliable sealing, use metallized tape.

For better air circulation in the doors of the rooms, free space is left below.

Methods for connecting plastic pipes

Polymer pipes are interconnected in several ways:

- by means of a coupling put on or inserted into the pipe;

- thermistor fittings made of special polyethylene with a metal spiral;

- butt welding using welding equipment.

Thermistors are heated using an electric current, the polymer melts, and a welded joint is obtained with a high degree of tightness and strength.

With the help of a soldering iron with a disc heating element, the ends of the polymer pipes are heated to a melt state. Then they are connected with a confident movement. After solidification, a virtually monolithic structure is formed in the seam zone

In butt welding, plastic surfaces are pressed tightly against each heating element, then connected with a confident movement. At the exit, a welded seam is obtained, which is not inferior in strength to the base material.

In self-assembly, it is recommended to use the simplest option for connections - couplings. To install them you will need soldering iron for polymer pipes, the so-called "iron". For a one-time job, it is more practical to rent it.

Regulatory requirements for the laying of ventilation pipes

Compliance with the regulatory requirements for the binding of air ducts to walls and ceilings, to each other, to utility networks will allow for installation without problems and troubles during expert acceptance of works.

The distance between the fasteners is no more than one meter. Contact with metal parts of the suspended ceiling is excluded so that noise and vibration are not transmitted to it.

The power of the exhaust fan installed in the premises of the house can be determined by the volume of the room and the rate of air exchange

Vertical deviation of the channel is allowed no more than 2 mm per 1 meter of pipe.

The minimum distance to engineering networks is 250 mm. Before the wiring - at least 300 mm.

The smallest distance between two round air ducts is 250 mm. Detachable connections are placed at a distance of at least 100 mm from the places of passage through walls and ceilings.

It is allowed to combine the channels of the bathroom, toilet, technical rooms with the installation of check valves.

Do not use plastic pipes for boilers and fireplaces.

The assembly of plastic elements into large blocks and spatial structures is within the power of even an inexperienced craftsman with a minimum set of tools. This applies to ventilation systems with natural air circulation without the installation of special complex equipment and automation units.

For the construction of a complex system with the installation of ventilation equipment, recuperation units, control units, it is possible you will have to seek help from installers from an organization specializing in the assembly of ventilation and heating systems.

In any system, even the simplest, it is important to accurately calculate the parameters, the availability of working drawings or layouts and fastening of air ducts, the installation of ventilation equipment.

Conclusions and useful video on the topic

The video clearly demonstrates how the exhaust and supply channels are laid in the kitchen and in the bathrooms. The places of installation of check valves and electric fans are shown. Explanations of the need for their installation are given:

Summing up, we can say that the list of advantages of polymer pipes far exceeds their disadvantages. This is a decisive moment in the choice of material for the installation of the ventilation system.

Lightness of structures, unification of parts, simple installation brought plastic air ducts to the forefront in equipment of low-rise residential buildings, utility and technical premises, low-rise public buildings.

Tell us about how you installed plastic air ducts in your own dacha or in a country house, how you assembled a duct for connecting an exhaust hood in the kitchen. Share some technological features that might be useful to your site visitors. Leave your comments, please, in the block form below.