A gazebo is something that a home craftsman can build with a minimum of skills in carpentry. And building a gazebo with your own hands from wood will become more accessible if at the planning stage you get acquainted with the drawings and diagrams, watch suitable videos. Is not it?

Next, we will tell you how to correctly draft a gazebo, calculate the required amount of materials for construction and independently build a stylish gazebo made of wood.

The content of the article:

-

Site selection for construction

- Design of wooden arbors

- Selection of materials for construction

- Pretreatment of lumber

-

Construction of the foundation for a gazebo made of wood

- Making the bottom and top strapping

- Fastening the pillars of the support and the upper strapping

- Flooring and handrail construction

- The roof of the wooden gazebo

- Finishing of the building

- Conclusions and useful video on the topic

Site selection for construction

The place for construction must be chosen where there is a good view. Much depends on the size of the site and the functional task of the building. It can be done in a secluded corner, away from

gatewhere nothing will disturb you during your vacation.Sometimes they are erected where it is planned to make a barbecue and there is access to water in order to turn this structure into a kind of place for a summer dining room.

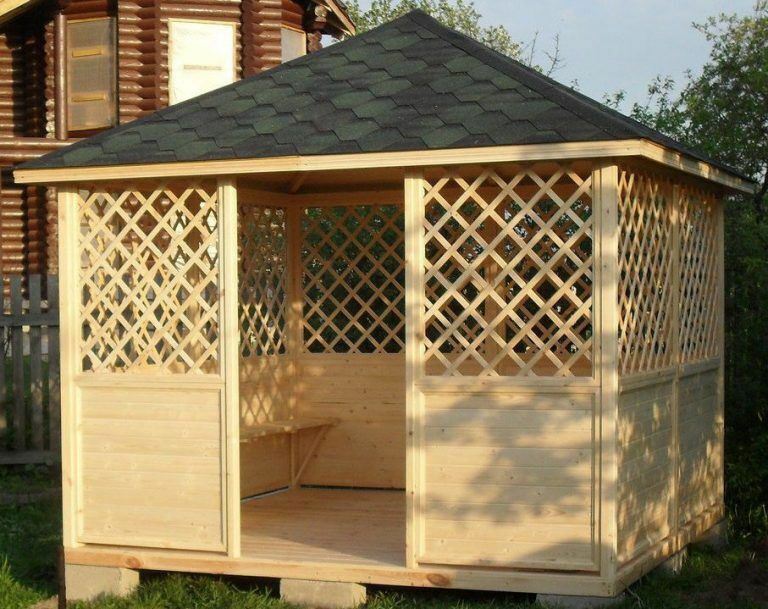

Wooden gazebo of rectangular shape with a hipped roof. Lower part of the gazebo with full planking and trellis in the upper part

If the dacha has a pool, then it is reasonable to build a gazebo next to it. On the site of a country house, where there is "wild nature" in the form of birches or pines, firs, it is better to make a light construction in this place, but not among the beds. It is better to separate the vegetable garden from it with a hedge of shrubs, tall flowers.

If you are used to arranging your own site on your own, then you will probably be interested in reading the article on the arrangement garden shower.

Design of wooden arbors

The gazebo should be an architectural whole with a country house, this is especially important if it is built next to it. In other cases, it is not necessary for it to copy the main structure according to the choice of walls or the shape of the building. It is enough that one of the elements is combined, for example, the roof structure or the details of the openings.

If the gazebo is located quite far from the house or under the shade of trees, then you can deviate from this rule. In the case of planning its construction near the hedge, then it is also necessary to think about the combination of elements.

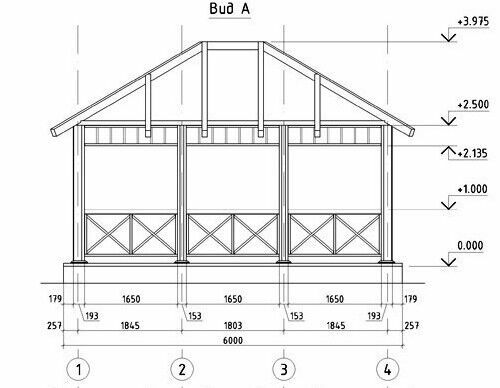

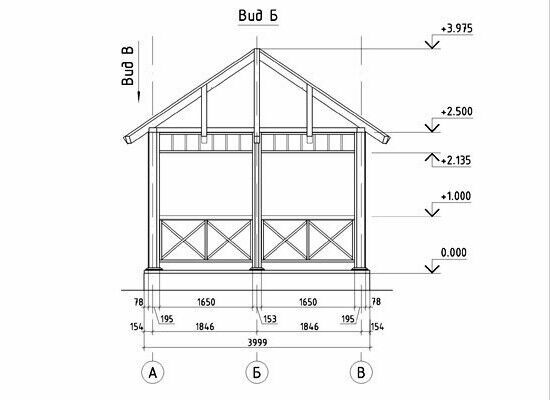

Scheme No. 1. Gazebo measuring 4x6 m, view from the long side. Digits 1, 2, 3, 4 correspond to the same digits in the following diagram # 2. The dimensions of the main elements are indicated in mm

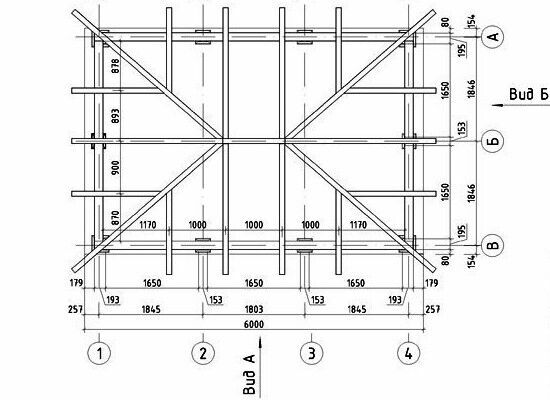

Scheme No. 2. Gazebo 4x6 m, top view. Digits 1, 2, 3, 4 correspond to the same digits in the scheme No. 1, letters A, B, C in the scheme No. 3. The roof of the gazebo is hip, hipped. Two side elements - hips, in the form of triangles, the other two - in the form of a trapezoid

Scheme No. 3. Gazebo 4x6 m, view on the short side with the main parameters of the building. Letters A, B, C correspond to the same designations in the scheme No. 2

Depending on the functionality of the gazebo, you need to take care of the need for removable screen frames that will help protect against bad weather or trellises for climbing plants. In advance, you need to think about whether there will be lighting in the gazebo, as well as from what material to make the track.

The arbors can be round, rectangular, in the form of a hexagon or octahedron in shape. The rectangular or quadrangular shape is most popular in the construction of a wooden gazebo. Such projects are easier to implement.

The roof, most often, is four-pitched, in multifaceted options - according to the number of edges. The simplest option is single-slope. It is not difficult to make a gable roof, but you can also make a structure with four slopes. It protects better from bad weather.

Home craftsmen often do not stop at simple solutions and approach the construction of wooden arbors with imagination. They use a variety of designs and materials, ranging from reeds and willow twigs to intricately curved tree trunks. Consider some options for ideas for wooden arbors from such skilled craftsmen.

An open gazebo made of logs, a very simple option. The table and benches are also made of this material, the roof is gable. Due to the columnar foundation, the building seems to float in the air

Made in a rustic style. Wood tinting makes the building look old. For sheathing the bottom of the gazebo, not a log was used, but only its lateral cut - a processed oblapol. Shingle roofing and openwork overhangs enhance the effect of antiquity

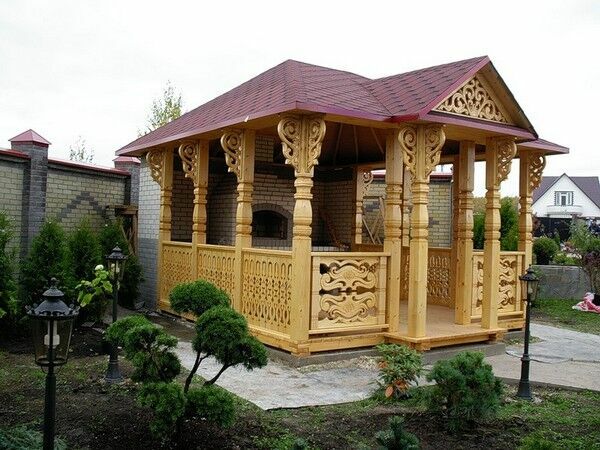

In this gazebo, the Russian style is emphasized by figured supports and varied carvings in the form of openwork balusters and a patterned pediment. This building with a hearth for cooking serves as a kitchen, dining room and outdoor living room.

A very interesting idea for a closed gazebo. First of all, these are glazed openings. There is a cooking hearth inside. The back wall is finished with shingles. The gazebo has two doors, one of which leads to a balcony-terrace. An unusual detail for a gazebo - an envelope-type roof, it is also called a folding

The original idea of a small round gazebo in a round shape. The highlight here is the multi-layered reed roof supported by four log-shaped pillars. She gives the impression of a tropical hut

At the design stage, you need to find and download or independently draw the simplest drawings and diagrams of the gazebo. Based on them, you can calculate the amount of materials required. It is always necessary to buy them with a small margin, so that in the event of a shortage, you do not have to stop work.

Selection of materials for construction

A wooden gazebo can be cut from a log or a bar, it looks especially beautiful if the house itself is also made of this material. This design looks harmoniously against the background of pines and firs.

For the basis of the gazebo, as support pillars, you can take rounded logs or timber. The rest of the trim and decor elements can be made of lighter material:

- block hausa;

- lining;

- grooved boards;

- slats of different widths;

- wooden balusters;

- picket elements.

As you can see, the choice of materials for construction is quite large, which makes it easy to build the gazebo of your dreams.

Pretreatment of lumber

An open-air gazebo is exposed to constant destructive effects of water, snow, sun, fungus, mold, insects can settle in it. Pretreatment of the materials is necessary to protect the wood.

Special mixtures have antiseptic and water-repellent properties. Before applying them, the lumber must be well dried.

It is important to impregnate the ends of wooden elements with antiseptic compounds, especially after the marking and fitting have been made.

Final painting or varnishing can be done after construction is complete.

Construction of the foundation for a gazebo made of wood

Lightweight gazebos with a wooden roof can be built without a special foundation. This is especially true for those structures when the roof and rafter system does not have a lot of weight. This option is also suitable where it is not planned to make the floor - you are going to leave it earthen or cover it with sand.

First you need to level the construction site by removing the surface nutrient layer. Next, you can fill the site with gravel, it is desirable that it has an elevation to the center. This will prevent water from flowing under the floor.

Pits are dug under the wooden support posts. The number of pillars is determined by the size and shape of the gazebo. For a square gazebo no more than 3x3 m in size and a sandy floor, four supports are enough. For large structures or for those where a complex rafter structure or a roof made of natural tiles, other heavy material, will need intermediate supports. Also, intermediate supports are needed for laying the logs.

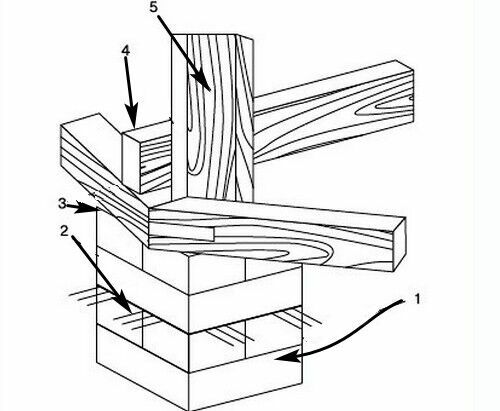

Drawing of a pillar foundation made of bricks for a gazebo made of wood: 1 - brick pillar, 2 - level of the soil surface, 3 - layer of roofing material, 4 - lag, 5 - pillar

The diameter of the logs must be at least 200 mm. Particular attention should be paid to the antiseptic treatment of the underground part of the support. It can be covered with pitch or, in extreme cases, burned over a fire. Pits about one meter deep are dug under the support beams. Gravel, fragments of bricks, etc. are poured to the bottom. mixed with sand.

The layer of such a tamped pillow should be about 20 cm. After the support is installed in the pit, the gap between it and the soil is filled with sand and gravel mixture and compacted. Such a foundation can last 15 years.

For a longer service life, it is necessary to make a columnar foundation with a shallow depth of laying.

Stages of building a columnar foundation for a gazebo:

- In the places of the supports, pits are dug half a meter deep.

- A gravel-sand mixture is poured onto the bottom.

- Formwork is installed along the perimeter with a size of 400 x 400 mm and a height of 150-200 mm.

- For pouring, concrete is used in the proportions: cement + sand + gravel - 1: 2: 2.

- Before pouring concrete, you need to put the reinforcement. The concrete hardening period is 2 days.

- This foundation can be completed on top with brick pillars, so that there is an elevation of two bricks above the soil level, or the pillar foundation can be completely made of brick.

In a quadrangular gazebo, supports are made in the corners, in the middle of each side and one in the center of the gazebo.

As a basis, you can also do slab foundation with a shallow depth of occurrence. First, the entire perimeter of the site deepens by 10-15 cm and formwork is installed around the perimeter. Further, the surface is filled up and gravel and sand are leveled. Compaction of the mixture can be done with water from a hose.

Reinforcement is laid on top and a concrete platform is poured. It can already serve directly as a floor or as a base for ceramic tiles, but you can lay wooden floorboards on it on logs.

Making the bottom and top strapping

A strapping from a bar with a profile side of 150 or 200 mm is laid on the foundation. The harness can be fixed on a mustache when the corners at the junction are cut at an angle of 45 degrees, this is important if the gazebo is rectangular.

You can use the half-wood method, when part of the wood is removed and the beams are inserted into each other or joined end-to-end.

Joining a bar in a half-tree way is a fairly simple, but reliable way of joining. It allows you to connect two identical parts at right angles.

The strapping beam is attached to the foundation posts using metal corners. You can immediately make the top harness, so that after installing the posts, raise it and install it on the supports. It just copies the bottom harness.

Fastening the pillars of the support and the upper strapping

Corner pillars of the support are attached to the harness. They can be secured in different ways. Let's consider one of them. First, the support is attached to the strapping with metal corners. Then it is leveled and temporarily fixed with an oblique rail on both sides.

The photo shows the attachment points of the support posts to the timber strapping, as well as temporary fixation with oblique slats. You can see how the lags are attached to the harness.

The top harness is also attached to metal corners. For greater reliability, you can drill holes through the harness into the support post and screw in a 250 mm screw.

At this stage, you need to install entrance racks or additional railing racks if the gazebo is more than three meters long.

Flooring and handrail construction

The floors are based on logs and black floor from the boards. The logs are laid on a concrete base or timber strapping. As insulation, it is necessary to use a bedding made of roofing material. The subfloor is installed with small gaps.

For the floor, use a board of 20 mm or more. Leave a small gap between the boards. This is done so that the water from the rain and melted snow does not stagnate on the floor and go into the cracks.

Railings can be fixed to metal corners. This is also done in another way: first, attach to the support pillars on self-tapping screws reiki. Put the railing on them and fix it. Install one beam diagonally, it will add extra rigidity.

During the full stitching the lower part of the gazebo with boards, they will be attached to this beam. It can also be an additional decorative element in the half-timbered style, if you add two more short bars to give the X-shape.

The roof of the wooden gazebo

The roof that will crown the gazebo can be: single-slope, gable, four-slope or multi-slope.

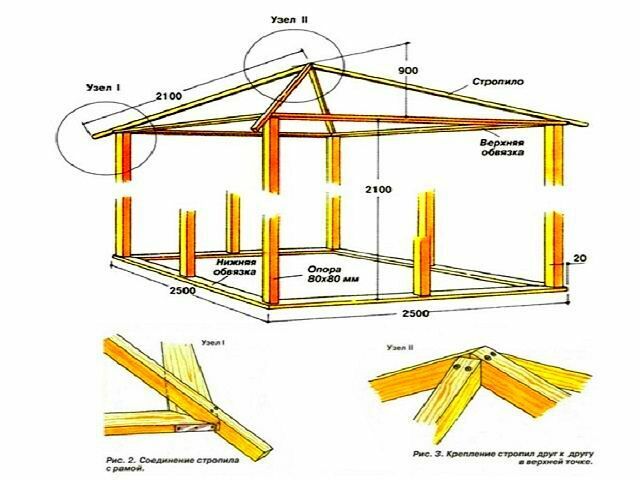

Drawing of the installation of the rafters of the hipped roof. In node 1, you can see the rafter attachment with the top strapping. Node 2 is the place where the rafters are connected at the top

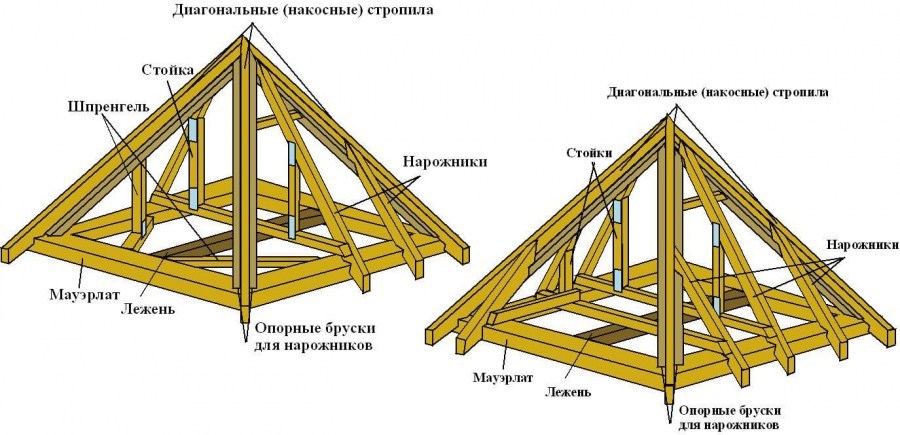

For a hipped roof, it is possible, during the installation of the upper trim, to make a cross using the method of connection inhalf a tree. To give the structure more rigidity, wooden blocks 40 x 40 mm are attached in the center.

A bar with an octagonal profile is attached to the center of the cross. It must be made independently from a bar with a side of 100 mm and fixed in the center of the cross. A cut is made in it from above to attach the first pair of rafters. They must first be fastened in half a tree, and then inserted into the cut of the bar.

Another pair of rafters, perpendicular to the first pair, are placed on the octagon and attached. We do the same with the rest of the rafters. Their ends should lie on the upper harness, dropping below them by about 30-40 cm.

A detailed diagram of the installation of four-pitched roof rafters for heavy roofing material. There are more elements to strengthen the rigidity.

Next, you need to make a crate. Depending on the choice of roofing material, it can be solid or sparse. The roof should be made identical with the house for a harmonious combination.

In addition to the usual roofing materials: natural tiles, metal tile, metal profile, shingles, slate, etc. you can use a board, shingles. There are rarer materials such as wooden shingles.

These are small boards, shingles. The shingle is attached with an overlap on the crate and looks very original, is environmentally friendly material. Another natural material is reed. Mats are made from it, which should be treated with a fire retardant against fire. The lathing for such a roof is not made solid, but with a step of 35 - 40 cm.

Finishing of the building

You can use different types of materials to decorate the gazebo. Even the railings themselves are made by many from the same timber, but wooden railings with beautiful balusters will look much more beautiful. For their attachment, holes are made in the lower bar using a feather attachment.

Each piece is inserted into the prepared hole. To temporarily fix them on the support pillars, you need to nail the rail. Next, a bar from the railing is applied to the upper part of the balusters and fixed with self-tapping screws. Glue is applied to the strip and to the underside of the railing where the groove is PVA. The railing is pressed against the bar. For strength, they need to be fixed to the posts using corners.

Wooden railings installed on curly balusters with a special strip. Balusters were mounted in specially drilled holes in the bottom bar

You can also make lattice screens in order to close the inside of the gazebo from prying eyes. You can make these tapestries yourself.

First you need to make a frame of bars, connecting them with a mustache or end-to-end. It is necessary to make markings on the frame. The first rail will go diagonally, the rest parallel to it with a certain step in both directions to opposite corners. Fastening is made self-tapping screws.

Likewise, the slats are attached in the second row to create a lattice. The slats do not have to be cut exactly to size first. They can be trimmed to the edge of the frame after being secured. Such a trellis can be fixed between the railings and the pillars of the gazebo. The frame will face inward and the grille attachment points outward. If from above the attachment points are closed with slats of the same width with the frame bars, then the whole structure will look neater.

Scheme for constructing a hexagonal arbor made of wood. The bottom is finished with lattice screens, which visually gives the gazebo lightness

Some craftsmen use natural materials found in the forest for railings and balusters: tree trunks and branches, peeled from bark and varnished.

If you plan to make the gazebo warm, so that you can stay there in cooler weather. Then the lower part must be completely sewn up with a board. In the upper part of the gazebo, a jumper bar is attached to the support pillars.

Such lintels are installed parallel to the railing, below the top point of the support pillars by 200 - 300 mm. This top gap also needs to be sewn up with planks. Special double-glazed windows are installed between the railings and the upper lintel for the cold period. For insulated gazebos, a light shield door should be installed.

In places where there are frequent winds, one of the walls of the gazebo can be completely sheathed with a board. You should also do if the neighboring area is close, and you want to isolate yourself from prying eyes.

At the end of construction, in addition to antiseptic treatment, the wooden gazebo must be painted or varnished. This will protect the building and give it a more noble look. The painted surface is easy to clean and easy to maintain.

Conclusions and useful video on the topic

Video instruction for the construction of a rectangular wooden gazebo:

Video with instructions for building a hexagonal gazebo:

Building a gazebo made of wood is not such a difficult business. To do this, you will need tools: a circular saw, screwdriver, drill, chisels, plane, grinder. Some woodworking skills, free time and a desire to decorate your site with a new functional and beautiful gazebo will also come in handy.

You can ask questions on the topic of the article or share your own experience in building a wooden gazebo. The communication block is located immediately below the article.