Each stage of connecting a house to a centralized gas pipeline must be carried out in accordance with regulatory documents and installation rules, therefore, only representatives of gas services have permission to work.

Let's dwell on one of the key stages of the equipment - the basement input. This term denotes a monolithic connection of two elements of a gas pipeline: a polyethylene pipe, which is laid in the ground, and a steel pipe, most often external.

Gas workers must also select parts and equip the exit of the gas pipeline from the ground, however, the owner of the house can control both the quality of the materials used and the observance of installation standards. And our article will help him with this, in which the normative regulations are analyzed in detail, schemes and examples of basement input are presented.

The content of the article:

- The main reference point is regulatory documentation

- Features of the gas pipeline outlet equipment

-

Types of basement inputs

- Option # 1 - L-shaped

- Option # 2 - i-shaped

- Option # 3 - straight

- An example of practical implementation

- What types of cases are used?

- Pipe protection recommendations

- Conclusions and useful video on the topic

The main reference point is regulatory documentation

In the future, during routine inspections or in the event of an emergency, the regulatory authorities will carefully inspect all units, starting from tie-in to the central pipe and ending with the connection of a gas boiler, stove or oven. And the first thing they will pay attention to is whether the installation method was chosen correctly - aboveground or underground.

A more acceptable, but also expensive way of supplying fuel to the house is underground. It is practiced if, in the future, the pipe is not affected by such factors as seismic activity, groundwater, road surfaces crossing the path.

The basement input is an element of the underground laying, therefore, further we will talk only about it.

But integrity and correct exit equipment gas pipe from the ground are important not only because of the risk of getting a large fine during the check. The main thing is to ensure the safety of the residents of the house and everyone who is nearby.

Any faulty equipment threatens a serious accident on the gas pipeline. In addition, if the basement input is incorrectly designed, gas leakage is possible, and this is additional spending from the family budget.

The outlet of the gas main from the ground to the outside is carried out directly near the wall of the building, so that provide the shortest path to the final point - the boiler, which is located in the kitchen or in a separate premises

During the laying of main pipes, installers are guided by the provisions set forth in Russian regulatory documents. For example, in SNiP 2.04.08-87 * all the nuances of the installation of polyethylene pipes, preferable for private use, are considered, as well as the requirements for the routes of their laying.

The depth of the gas pipeline laying is also regulated here - 0.8 m.The exceptions are territories where no traffic is foreseen - 0.6 m. data must be taken into account when sizing equipment for a gas pipeline exit device from the ground, although factory products are usually tailored to the standard scale.

It is undesirable for underground waters to be present near the place of installation of the input unit. If they are still there, it is necessary to take measures to prevent deformation or floatation of the polyethylene pipe.

Specific information on underground gas pipelines can be obtained from SNiP 42-01-2002. It contains useful materials on the use of cases - special protective elements, as well as on the conditions for using polyethylene pipes.

It is interesting that two or even more gas pipelines can be located in one trench, but so that free access to each of them is provided during repairs.

During pipe-laying, workers may be faced with the fact that the gas pipeline intersects with other utilities. This is not difficult, since the permissible distance between the nets is only 20 cm.

All stages of construction, from project development to commissioning, must be carried out according to the norms SNiP 3.02.01-87, PB 12-529-03 and SP 62.13330-2011.

Features of the gas pipeline outlet equipment

It is impossible to independently manufacture parts for the equipment of the basement entry.

They are produced in the factory from materials that meet the requirements of GOST:

- longitudinal welded steel pipes (10705-80 or 3262-75);

- seamless pipes (8734-75 or 8732-78);

- polyethylene pipes (50838-95).

It should be remembered that all connections of the lead-in part with the gas pipeline must be one-piece - both those that are underground and those that are located outside. Steel elements are welded and insulated. Although the residential sector is supplied with low pressure gas, adapters are often designed to handle medium or high pressure fuel.

Read more about the pressure in the gas pipeline - read Further.

According to the installation rules, the length of the above-ground part of the highway, placed in a case or simply insulated, should exceed the height of a stable snow cover by 0.2 m (on average)

The length of the lower part depends on the conditions of installation and burial of the gas pipeline. But it must be remembered that the trench is never laid below the base of the foundation of the house. It turns out that all the details of the entrance of the gas pipeline into the ground should be located on the segment from the bottom point of the foundation to the windows of the 1st floor.

The polyethylene-steel connection is most often located in a more protected horizontal section, which is located in the ground. In this case, one of the requirements is a temperature not lower than -20 ° С

The correct temperature regime can be ensured by insulating a polyethylene pipe and an integral connection. In the southern regions, thermal insulation is not required, but mechanical stress on the connection unit must be excluded.

Types of basement inputs

There are three types of nodes for the exit of the gas pipeline from the ground, as well as their options - in a case or without it. All presented structures are intended for installation in the places where the gas mains exit from the ground, they are suitable for gasification of residential buildings, that is, networks with low pressure.

Let's consider in more detail how they differ.

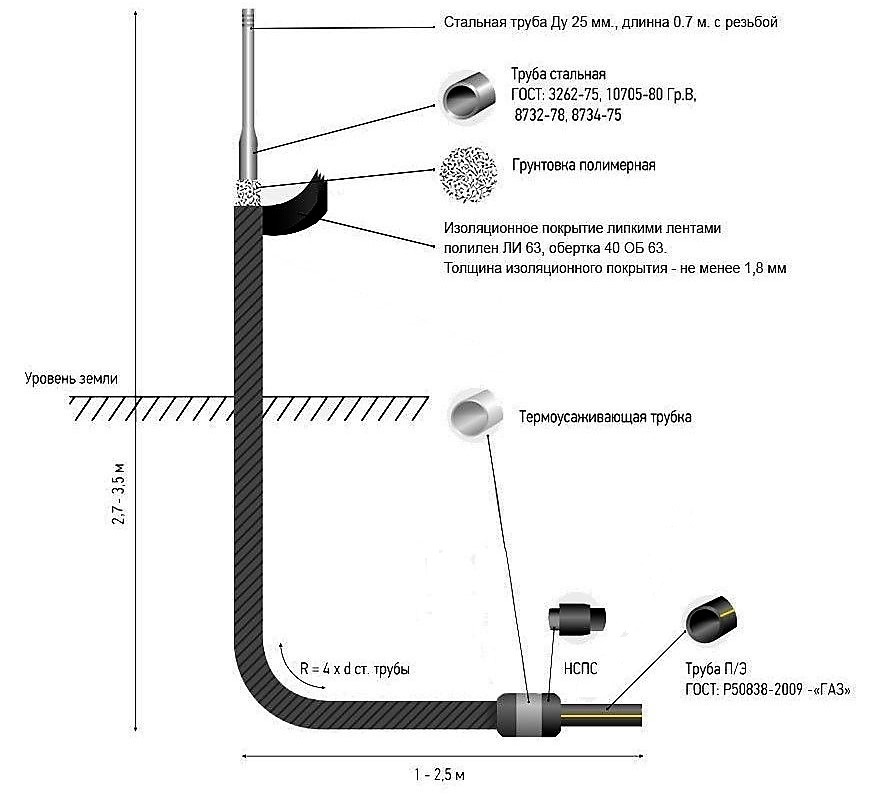

Option # 1 - L-shaped

This is the most common type of construction, having the shape of the letter "L" and resembling a poker. It is usually made of two types of pipes - steel and polyethylene. The steel part is cold-bent, without welds, and protected from corrosion by extruded polyethylene or other moisture-resistant material.

Scheme of the CVPS with an indication of the material of manufacture and methods of connecting the structure with pipes. A monolithic polyethylene-steel assembly is located on the horizontal, underground section of the product

The location of the permanent connection underground, on a horizontal section, protects it from freezing in frosts, typical for northern regions with a harsh climate.

Products are made in factories, where they are covered with a layer of insulation. Already in the field, the connection units are protected with adhesive polymer tapes, the layer thickness is at least 1.8 mm

In addition to conventional designs, products with a transition are produced. This is a metal piece with a standard diameter of 25 or 32 mm, made by rolling and welded.

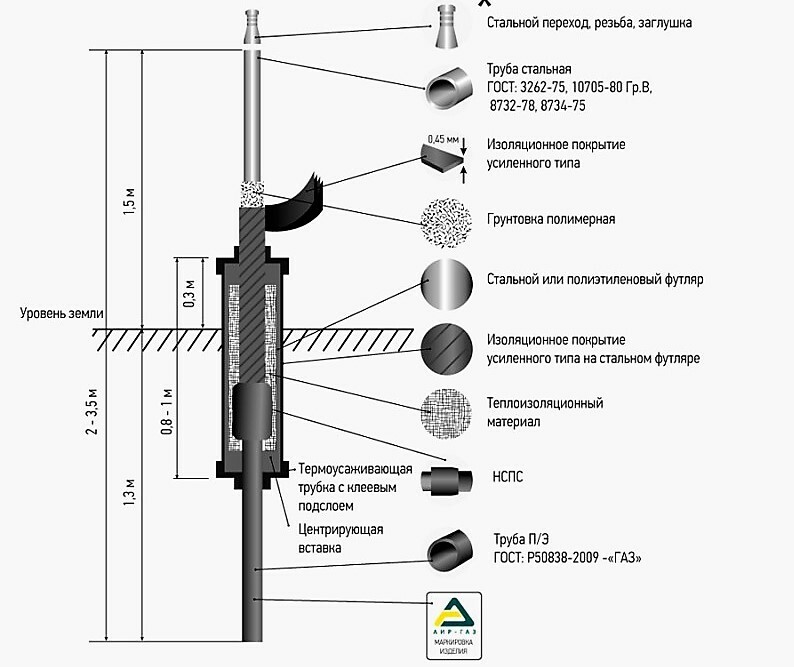

Option # 2 - i-shaped

The material for the manufacture of i-shaped structures is the same as for the production of L-shaped analogs - polyethylene and steel pipes of GOST standards. They are also designed to provide gas supply to residential buildings - summer cottages, cottages.

A feature of the products is the location of the polyethylene-steel transition. It is not located on the horizontal part, as in the alternative L-shaped product, but on the vertical, but underground.

Scheme of the i-shaped basement input. Due to the location of the permanent connection on the vertical part, the product is suitable for installation in any type of soil

Thermal insulation and a metal case are used to protect the connection. i-shaped structures, even the most insulated and insulated, have temperature restrictions. They are installed in areas where the air temperature in winter does not drop below -15 ° C.

Residential buildings are usually connected to low pressure gas, however the i-inlet is suitable for fuel supply and medium / high pressure.

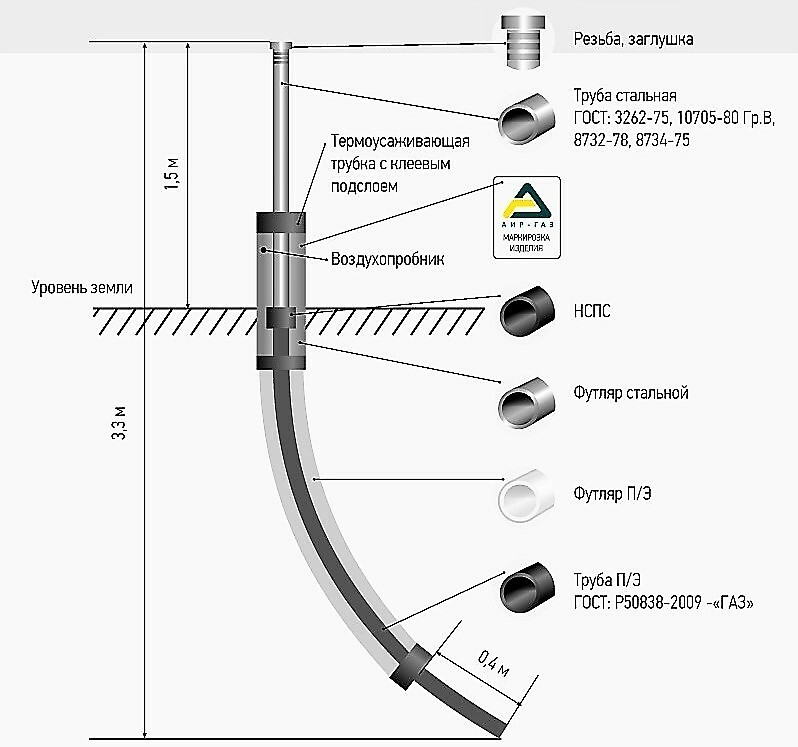

Option # 3 - straight

The main difference between the direct exit of the gas pipe from the ground is that it consists entirely of polyethylene, which ensures free bending. The second feature is its use only for the residential sector, since it does not withstand medium and high pressure fuel supply.

The polyethylene-steel transition is located at the top, on the vertical part of the product. It is enclosed in a durable metal case to protect it from mechanical damage and the effects of atmospheric agents.

Direct inputs are located near residential buildings, in the immediate vicinity of the connection point for household appliances - boilers, stoves, ovens.

An example of practical implementation

For a more thorough understanding of the process of putting gas into a house, we propose to consider an example - gasification of a summer house.

The gas line runs close to a residential building, just 10 meters from the fence. When collecting documents, it turned out that the soil is ideal for laying a pipe and additional measures to strengthen the main line are not required

The house is located on a plot with a vegetable garden and trees, so when digging a trench, I had to "wind" between pines and apple trees.

In total, the distance from the tie-in to the central highway to the basement input is 70 m.The depth of the trench is 1 m, the width is 35-40 cm. This is enough to lay the pipe, and in case of repair, take measures to replace it.

Image gallery

Photo from

To remove about 20 cubic meters of soil, it took the efforts of two excavators. During the day, the trench was prepared for the installation of the pipe and the input unit

To get out of the ground to the outside, the polyethylene pipe was connected to an L-shaped basement element, the vertical end of which is just above the foundation

Backfilling was carried out with soil that remained from the dug trench. The backfill layers were compacted, and a bright signal tape was stretched at a distance of about 50 cm from the bottom of the trench

The outer metal part of the basement input is insulated, and not a polyethylene pipe, but a steel pipe, is connected to it. On the wall near the gas pipeline - a metering device for used fuel

Trench from the central gas pipeline to the house

Basement input - L-shaped structure

Backfilling of the trench and gas pipeline exit

Outdoor structure and gas meter

Further, the line runs along the wall and is divided into two branches, one of which goes to the gas stove, the second to the household heating boiler.

The design of the basement entry from the presented example is a sample of the exit of the gas pipeline from the ground in a case, a protective metal case.

There is an article on our site where we examined in detail the process of gasification of a private house. Recommended reading.

What types of cases are used?

Gas workers themselves determine which type of basement input is optimal for specific conditions, they also choose a protective case and how to install it.

Depending on the configuration of the product, it is placed in one of the cases:

- flexible split polyethylene;

- metal.

Both types are produced under basic conditions.

For the manufacture of an elastic case, a polyethylene pipe, cut in half lengthwise, is used. During installation, it is glued with a sealant, wrapped along its entire length with adhesive tape and clamped with metal clamps.

To prevent debris or water from getting inside the protective cover, press it with a sealant from the ends, and then install plugs

The metal case is made of steel and mounted on the product during the installation of the input into the house. The cavity between the gas pipe and the cover is filled with either spun flax or rope, and then from both ends it is sealed with mastic by about 20 cm.

The outer part is covered with a primer and yellow metal enamel in two layers - according to GOST 6465. Such protection should protect the metal from corrosion and rapid wear.

Both types of cases should maximally protect the polyethylene-steel transition from external influences, as well as ensure the reliability and stability of the structure.

Pipe protection recommendations

Usually, representatives of organizations that install the gas pipeline in the house act strictly according to the instructions. Any violation of the installation rules is fraught with big troubles for home owners and penalties for gas workers.

You need to conclude a contract for connecting a house to the Central Gas Supply Center with a supplier company or representatives of an organization serving the main gas supply in your area.

However, sometimes the craftsmen make mistakes, so we recommend that the owners of cottages and country houses closely monitor the work of specialists.

Here are some helpful tips:

- If you know for sure that heaving soils are characteristic of your territory, require the installation of a basement input in the case.

- If there is a risk of flooding by surface water through the backfill soil, then a blind area with a 3-centimeter slope must be built. For structures without a case, the blind area should rise 0.15 m above the ground.

- To protect the structure inside the case, plugs are installed. The top is made mushroom-shaped.

- The caps of the case must have the necessary characteristics of moisture resistance, resistance to UV radiation.

- The vertical part of the bushing should be perpendicular to the horizontal, without a slope.

- After installation, the case should not sag; if necessary, use special supports.

Only non-porous soils, sifted and dense, without large inclusions, are suitable for backfilling the bushing structure. Every 25-30 cm of the backfill is carefully tamped to fill the sinuses.

For connecting gas to the house not only ready-made factory basement input is used. It is connected to the intra-house mains with pipe sections, which often need to be bent. For this, gas workers always have special equipment and special tools with them.

The gas service vehicle is equipped with the necessary tool: a universal type pipe bender for any diameter, welded equipment, workbench with a vice, coils with polyethylene pipes and tapes for sealing

Usually workers use their own material - good quality and tested at other sites, but the owner has the right to request certificates for materials and check whether they correspond to what is specified in project.

Conclusions and useful video on the topic

Basement entry overview - outside and inside:

Gas inlet to the house from the gas tank:

Measures for putting the gas pipeline into the house:

Installation of a basement input is just one of the stages of connecting a house to a highway supplying natural fuel, but you need to take it seriously and responsibly. We recommend concluding an agreement with a service company that will install, connect, test, and in the future will monitor the operation of the gas pipeline.

Do you have any questions about the topic of the article? Ask our experts - the contact block is located below. You can also add valuable information to the material or participate in the discussion.