The breakdown of any element of the heating system usually completely stops the process of heating the house. The most problematic place in the circuit is the boiler, which consists of many nodes. The complexity of the design makes repairing it difficult.

However, not everything is so bad, since malfunctions of Daewoo gas boilers, for example, can be detected almost instantly thanks to the flawlessly functioning display system. Of course, not all problems can be fixed on their own, but in some cases, you can do without the services of gas workers.

You will find everything about the decoding of error codes that occur during the operation of Korean equipment in our article. We will tell you how to react to the data of the self-diagnosis system. We will show you how to quickly solve the problem and restore the heating in full.

The content of the article:

- Daewoo gas boiler series

-

Errors and methods of their elimination

- Error type "E0"

- Error type "E1"

- Error type "E2"

- Error type "E3"

- Error type "E4"

- Error type "E5"

- Error type "E6"

- Error type "E7"

- Error type "E8"

- Error type "E9"

- Error type "EA"

- Error type "EC"

- Error type "Ed"

- Error type "EE"

- Error type "EF"

- Error type "U0"

- Error type "U1"

- Error type "U8"

- Error type "U9"

- Conclusions and useful video on the topic

Daewoo gas boiler series

Daewoo is one of the most famous Korean conglomerates that ceased to exist in 1999. Many divisions of the concern gained independence or merged into the structure of other firms.

Now in South Korea there are two companies that were previously related to the corporation and produce gas boilers:

- Altoen Daewoo Co., Ltd (until 2017 - Daewoo Gasboiler Co., Ltd). Now production facilities are located in g. Dongtan.

- Daewoo Electronics Co., which manufactures gas equipment at the factories of the KD Navien company.

Components for boilers of both companies are made in South Korea and Japan, and the assembly is carried out in an automated mode.

Altoen Daewoo Co., Ltd did not transfer production facilities to Chinese industrial clusters in order not to lose the opportunity to constantly monitor the quality of products

The following lines of gas boilers from Altoen Daewoo Co. are presented in Russia. Ltd:

- DGB MCF. Boilers with an open combustion chamber.

- DGB MSC. Boilers with a closed combustion chamber.

- DGB MES. Condensing boilers with a closed combustion chamber. The models of this line have a weekly programmer of work, an autonomous control panel, and also a simplified chimney connection.

All models of the listed lines are wall-mounted, double-circuit, that is, they are designed for heating and hot water supply.

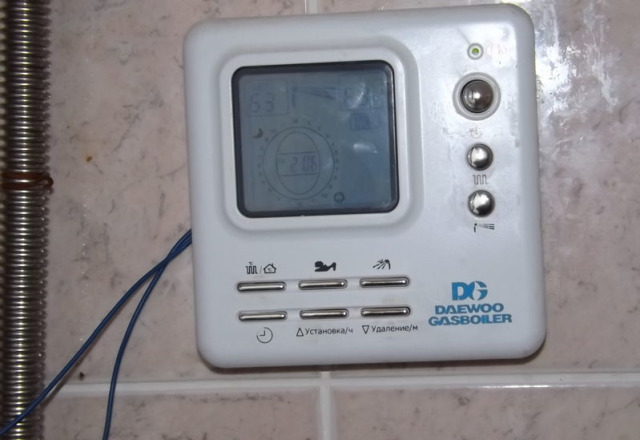

DGB series models are equipped with an informative display that shows an error code if a problem occurs or the built-in self-diagnosis system is activated

Daewoo Electronics Co. there are two lines of gas boilers: wall-mounted "DWB" and floor-standing - "KDB". They have their own characteristics, including error codes that differ from the competitor's models. However, these boilers are not widely used in Russia.

Therefore, the article will only contain error codes for gas boilers of Altoen Daewoo Co., Ltd.

Errors and methods of their elimination

The number of automatically detected malfunctions for Daewoo boilers is grouped into 19 events, each of which has its own code. Seeing the display, you can try to solve the problem yourself or give the called masters a first idea of the problem.

Some malfunctions of gas boilers do not depend on the type of combustion chamber or other features of the equipment. And there are problems that are specific only to a certain line. Daewoo Altoen (Gasboiler) boilers have sequential numbering of errors, and the methods for eliminating them are almost the same for all models.

Error type "E0"

This code signals an error in the room temperature sensor, which is built into the control panel. As an example of this malfunction, it can be seen that it is far from every time that you need to call a repair team.

It is necessary to disassemble the device, clean the contacts and check the sensor with a tester. It must be replaced if necessary. If you do not have the skills to disassemble and repair such products, then you can take the remote control to any workshop specializing in electronics.

Error type "E1"

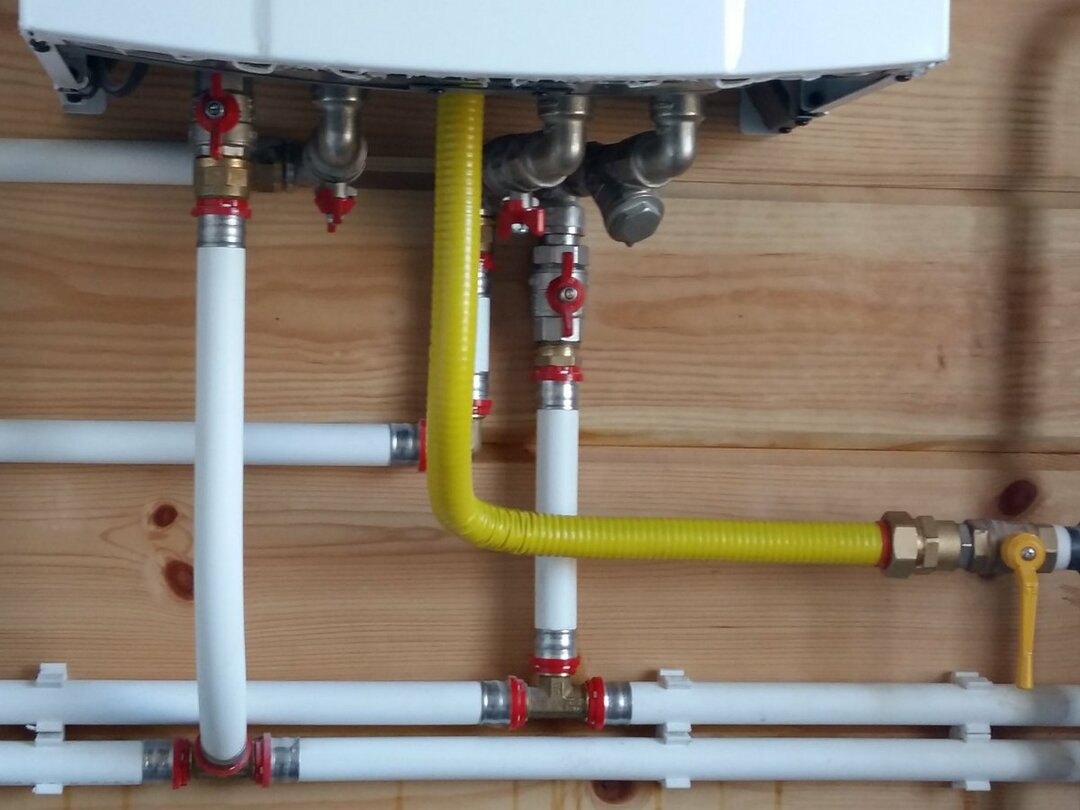

A decrease in pressure in the heating system was recorded. The simplest case that leads to this problem is the breakdown of the minimum pressure switch or the lack of a signal between the sensor and the control board. However, the first step is to immediately check the heating circuit for leaks.

Leaking pipes or radiators can occur in places where the presence of water is not immediately noticeable. These are interfloor ceilings, storage rooms or a basement. Therefore, you need to consistently bypass the entire contour.

A coolant leak can occur not only in the circuit, but also in the units of heating equipment, such as:

- heat exchangers;

- hydraulic pump;

- relief valve;

- make-up tap, etc.

In this case, the hydraulic system will have to be changed, although sometimes replacing the gaskets may be sufficient.

Also, the make-up may be cut off for some reason. Although in this case, the issue of leakage also arises, which is gradual.

A decrease in pressure in the circuit without a leakage of the coolant can occur in the event of a drop expansion tank pressure closed type, which is installed in the boiler. In this case, it will have to be repaired.

After eliminating the cause of the leak, the circuit must be filled with the restoration of the operating pressure.

Error type "E2"

A gas analyzer has triggered, signaling an incomplete combustion of the supplied mixture or the ingress of smoke outside the chimney.

The problem lies in insufficient traction, which can be caused by:

- Change in the free area of the flue duct as a result of its pollution. It rarely happens, mainly due to the ingress of a foreign object or a small animal there. Icing is also possible in the area of the pipe outlet. Gas boiler flue need to be cleaned.

- Strong wind back. Difficult case, since it is necessary to re-calculate the geometry of the pipe or install a wind protection structure.

There may also be a problem with the fan. Most often it is contamination of the blades, which can be seen or a violation of rotation, which is easy to hear.

The chimney for a gas boiler has parameters that are different from the hood of a stove heating. The fact is that the temperature in the boiler burner is relatively low, so the traction force will be less

The problems described above can be identified on your own. If the chimney and fan function normally, then there is a possibility of sensor breakage. It will have to be replaced.

Error type "E3"

The error occurs when fixing the fact of overheating coolant. There are two main reasons:

- malfunction of the emergency thermostat;

- slowing down or stopping the circulation of the coolant.

If such an error occurs, you need to wait until the device cools down, reset it (turn it off and on) and start it again. If the error repeats, then this means that the operation was not false (this happens) and you will have to figure it out.

First of all, it is necessary to determine whether the circulation rate of the coolant is sufficient. To do this, start the boiler without heating and listen to the pump. Its hum should be normal.

Problems with this node can be caused by several reasons:

- Lack of power supply. We'll have to ring the wiring and find a break.

- There is power, but the pump is not working. Show it to an electrician. If there is a break in the winding, then it is cheaper to replace the entire unit. If other wires are broken, the problem can be eliminated and the pump will work again.

- Rotor shaft seizure. Such an event rarely occurs without damage, so it is best to replace the pump.

- Impeller wear. The pump needs to be replaced.

It is also possible that the contacts of the signal wire from the pump to the board are disconnected or the central board itself breaks down.

Poor circulation of the heating medium can be caused by a clogged dirt filter. It needs to be cleaned periodically, but not everyone completes this procedure on time.

If the pump is running at full capacity, the cause of the poor circulation is in the circuit. She may be:

- Decrease in pressure in the system and failure of the pressure sensor. Rare case.

- Airlock formation. It is necessary to check the entire circuit by bleeding air through Mayevsky taps and similar fittings.

- Accidental closure of one of the valves. Check all taps and plugs.

- Blockage formation. Rare case. A difficult problem primarily due to the difficulties associated with finding the place of the mud plug.

If the pump is working normally, and the circuit regularly passes the coolant, then the temperature sensors need to be replaced. Most likely, they are out of order.

Error type "E4"

This code signals the actuation of a pressure switch - a draft sensor in the chimney. The main reasons are the same as for the error with the “E2” code.

If the chimney of the gas boiler and the fan are working normally, then the problem may lie in the signal from the sensor. First of all, you need to check the tightness of the connection of the contacts to the sensor and to the central board, as well as ring the wiring.

It is also possible for condensation to form in the pipes or poor connection to the sensor. Breakage of the pressure switch itself is unlikely.

Error type "E5"

Alarm received from the flame sensor. If, visually, when the boiler is turned on and off, ignition proceeds normally, then the flame sensor must be checked.

First of all, you need to make sure that it is in good contact with the main board (check the wire connection and ring it). You also need to make sure that there is a voltage of 5 volts between the terminals of the CN05 sensor.

If there is no ignition, the problem may not be in the boiler. The position of the gas shut-off valve should be checked first.

If the sensor is working properly and the ignition does not cause problems, then there is an error in the central board. It will have to be replaced.

If you can visually detect a problem with ignition, then you must perform the following steps:

- Reset the unit and try firing up again. Perhaps the reason is one of the capacitors or the residual charge on the ignition transformer.

- Make sure that the maximum and minimum gas pressure for the injectors installed in the device is correctly adjusted. Refer to the instruction manual for the standard values.

- Inspect the ionisation electrode for contamination. Make sure of the permissible gap between it and the burner. Make sure there is a spark (by shutting off the gas beforehand).

- Adjust the ignition power in the service menu. You need to use the parameters that are written in the user manual.

- Make sure that there is no breakdown to the body (that is, the user does not receive an electric shock when touching the elements of the boiler).

- Make sure that there is and is not a break in grounding.

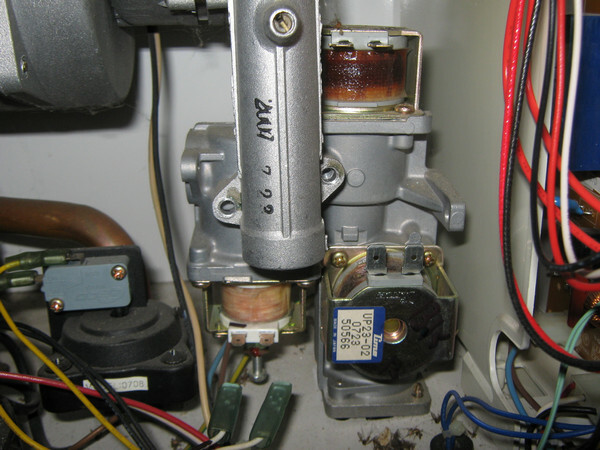

- Check the gas valve for sticking. It is enough to insert the silicone tube into the fitting and press firmly.

- Ring for a break in the valve coil.

If the problem is in the gas valve, then it will have to be replaced.

Often a break in the gas valve coil (top) and other electrical faults can be recognized visually or by the characteristic smell of burnt wiring.

Using this error as an example, it can be seen that sometimes knowledge in several areas is needed to repair a Daewoo gas boiler: electrical, electronics, mechanics. Therefore, in case of complex errors, it is still better to call experienced gas service technicians, with which contract signed for the supply of blue fuel and maintenance of units.

Error type "E6"

Gas leakage sensor triggered. If there is a smell of gas in the boiler room, then it is necessary first of all to turn off the shut-off valve at the entrance to the house. Then you need to check the gas pipeline (up to the boiler valve) and fittings for damage. If you find them, you should contact the gas service.

If the smell of gas is not felt, the boiler can be restarted after a while. It is advisable to be nearby at this time and have a gas analyzer with you. If the sensor is false, then it needs to be replaced.

Error type "E7"

This code is displayed if the board has “lost” the remote control. The problem may be a breakdown of the control panel or the board unit responsible for communication.

Control devices from other Korean manufacturers (Navien, Hydrosta, etc.) are suitable for Daewoo boilers, so there is no particular problem in replacing this part.

Error type "E8"

Interruption of communication between the temperature sensor of the heating circuit and the central board. Typically, the problem arises when the thermistor breaks down. First, of course, you need to see if the contacts have come off, then ring the wiring. If it is in good working order, then the sensor should be replaced.

You can replace the sensor yourself. All modern measuring devices of this purpose are equipped with special sockets, so nothing needs to be soldered

It is theoretically possible for the central board unit to break down, although usually in this case it is completely, rather than partially, out of order.

Error type "E9"

Leakage in the boiler. The water sensor has triggered. You need to open the boiler and look where the fistula has formed. There may also be a problem in the gaskets of the nests where the heating and hot water temperature sensors are installed.

Error type "EA"

The circuit is replenished with water more often than once every 5 minutes. This indicates a leak. Its volume is not so significant as to stop the boiler as a result of water boiling or pressure relief.

This situation cannot be ignored, since a small leak at any time can turn into a full-fledged rush with an emergency stop of the boiler and serious consequences for those in the house items.

Error type "EC"

Central control boards are universal for all models within the same range. The error code “EC” indicates an incorrect choice of the boiler model. This usually happens when the main board is replaced or when the parameters are reset due to a sudden power outage.

It is customary to install a stabilizer in front of the gas boiler. This avoids damage to expensive electronics and equipment downtime during the heating season.

To solve this problem, it is enough to configure the parameters using the service menu.

Error type "Ed"

The second letter of this code is the lowercase “d”. Manufacturers have moved away from the template so that users do not confuse the uppercase "D" and the number "0", which have similar outlines. An error means that the built-in stabilizer has detected a deviation in the frequency of the current.

If the electricity parameters often deviate from the standard values, then the boiler electronics may fail.

Error type "EE"

This code indicates a problem with the operation of the smoke exhaust fan. The RPM sensor shows a low value.

The malfunction can be caused by:

- a clogged impeller;

- violation of shaft lubrication;

- inaccurate sensor readings.

Also, a board error cannot be ruled out, although this option is unlikely.

Error type "EF"

Signal that the three-way valve responsible for switching the water flow has been open for more than 90 minutes. This indicates its jamming. To prevent this damage, it is necessary to install a filter that will prevent clogging.

The three-way valve is equipped with power wires and a communication loop with the central board. If an “EF” error occurs, first of all, you need to ring the wiring and secure the contacts well

The most serious failure is a burnt out valve servo. In this case, it is better to replace the entire distribution unit.

Error type "U0"

The flame sensor does not “see” the fire. Ignition problem. If the flame ignites and goes out, then the reason may be the quality of the supplied mixture, the gas pressure or the absence of a hood.

The chemical composition of liquefied gas differs from the main one. Each specific mixture has its own set of burner nozzles. Don't forget to put the right kit

If the flame ignites, the auto-ignition electrode continues to click, but the error still remains, then the reason may be a defect in the sensor or a poor-quality connection to the board.

One of the defects of the sensor is just its pollution. If you wipe this part, then the problem is often solved.

Error type "U1"

The buttons on the control panel are lit. Such repairs do not directly relate to the gas boiler, but any electronics specialist can carry out it. To do this, it is necessary to disconnect the panel from the boiler body and take it for repair.

Error type "U8"

Hot water temperature sensor error. The reasons for the breakdown and the necessary actions in this case are similar to the situation with the error “E8”. The boiler does not stop its work, but only functions in the heating support mode.

During the replacement of the sensor, the boiler will need to be stopped and disconnected from the power supply.

Error type "U9"

Signal from a temperature sensor located in the chimney. The most likely situation is pipe clogging. They need to be cleaned. If no contamination is found, the problem may be with the faulty sensor.

Almost half of the Daewoo gas boiler shutdowns are associated with problems that have arisen at other nodes of the heating circuit.

In addition, many boiler malfunctions can be eliminated on your own if you have at least minimal skills in repairing any equipment. Therefore, it is necessary to analyze the type of error and only after that make a decision either to repair it on your own, or to call specialists.

Conclusions and useful video on the topic

Replacing the heat exchanger of Daewoo MSC series boilers:

Determination of the type of malfunction associated with the ignition electrode:

Instructing a specialist in working with boilers of the MSC series. Suitable for other Daewoo lines as well. Accurate adherence to these guidelines prevents many malfunctions from occurring:

Remember that improper handling of flammable gas can lead to an emergency - fire or explosion. Therefore, if there are doubts about the possibility of solving the problem on your own, it is necessary to call the masters from the service center or gas service.

Tell us about your own experience in identifying and eliminating breakdowns of Korean-made gas units. It is possible that your advice will be useful to interested site visitors in solving their problems. Please leave comments in the block below, ask questions and post photos on the topic of the article.