The basis of autonomous heating systems is most often a reliable gas unit from a responsible supplier. But even the products of firms that are highly rated for the quality of the equipment produced have problems. Sometimes it is necessary to repair Ferroli gas boilers; not only gas workers, but also the owners themselves can cope with it.

Devices of this brand do not differ much from each other in terms of the principle of operation. Therefore, the problems that arise are typical for them. The ways of solving the arisen malfunctions are also well researched.

We will tell you how to correctly identify a malfunction. We will help you understand the problems and correctly decipher the error code displayed on the electronic display of the unit. Compliance with our recommendations will provide home craftsmen with a positive result of their efforts.

The content of the article:

- Fault indication on different models

- List of errors of gas boilers Ferroli

- Original and compatible nodes

- Conclusions and useful video on the topic

Fault indication on different models

Ferroli boilers are equipped with a self-diagnosis system and, in the event of an abnormal situation, give the user an error code. Knowing the type of malfunction, you can quickly find the cause of its occurrence. Many breakdowns do not require special knowledge to fix them.

All problems that arise during the operation of Ferroli boilers are conditionally divided by the manufacturer into 2 categories:

- Fatal errors causing full blocking. They are designated by the letter “A” before the code. In the event of such a malfunction, it is necessary to eliminate the problem and restart the boiler by pressing the “reset” or “reset” key.

- Problems causing temporary shutdown of the boiler or one of its components. They are designated by the letter “F” before the code. The automation is waiting for the situation to normalize, after which it will restart the boiler itself.

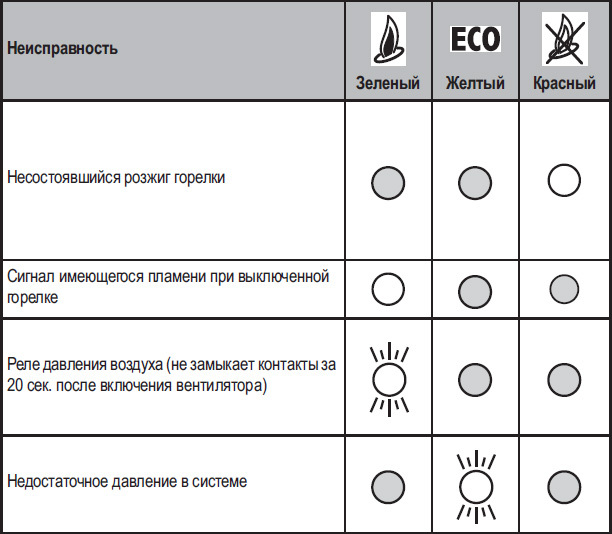

Error code information can be displayed on the LCD or remote control. For older models, you can find out the type of breakdown by indicators.

If the boiler does not have an LCD display, the type of error can be recognized by the flashing lights. A unique combination of indicator behavior is spelled out for each problem in the user manual

Also, sometimes a code starting with the letter “D” appears on the screen. This is technical information that warns the user that the boiler is changing over from one mode to another.

List of errors of gas boilers Ferroli

Below is a list of Ferroli gas boilers faults, sorted in ascending order of error code. For each problem, solutions are suggested, starting with the easiest one.

Error A01 - the burner did not light up. A common problem as there are many reasons for it:

- Lack of gas. It is necessary to check that all shut-off valves are open. If the gas was connected recently, then before starting the boiler, you need to bleed the air.

- Insufficient ignition power. You need to adjust this figure according to the directions in the user manual.

- Gas valve malfunction. It is possible that the wiring was incorrectly connected or there is a defect in the loop. There is also a possibility of a malfunction of the valve itself, then it will need to be replaced.

- Ionization electrode problem. You need to check the nominal gap, which should be about 3 mm, make sure the cable is in good condition and, finally, clean this part of dirt.

If all else fails, then the control board error remains. Although this is an unlikely event, as the self-diagnosis identifies problems with the boiler electronics well.

Insufficient pressure of liquefied gas can be caused by the onset of cold weather. This happens if the gasholder is filled with a “summer” mixture. The boiler will have nothing to do with it

Error A02 - signal about the presence of a flame when the burner is off. The most likely problem is current leakage from the ionization electrode circuit. Check the wiring for physical damage and short circuits. Also, the cause of the breakdown may be a malfunction of the boiler board.

Error A03 - boiler overheating. The most likely source of the problem is poor circulation of the coolant in the circuit.

This happens most often for three reasons:

- blockage formation;

- airiness of the system;

- malfunction of the built-in circulation pump.

In any of these cases, a strained operation of the pump will be heard. If the water is pumped normally, then you can check the temperature sensor itself and the wiring to it.

Error F04 - the smoke thermostat has tripped. A high exhaust temperature means that the heat exchanger is dirty. Also, the sensor can be triggered when the thrust rollover effect occurs.

Basically, the malfunction manifests itself due to problems with flue gas boiler. These can be both constructive miscalculations (small diameter of pipes or strong wind load at the outlet), and narrowing of the passage due to the ingress of foreign objects there or the accumulation of a layer of soot. Therefore, first of all, you need to check the smoke exhaust path.

The calculation of the parameters of the chimney for a gas boiler must be taken seriously. The alteration will take a lot of time, during which there will be no heating

You also need to look at the temperature setting for the sensor. It must match the boiler model. Finally, failure of the sensor itself is possible. In this case, it will have to be replaced.

Error F05 - fan failure. Depending on the model, the malfunction is determined either by the readings of the fan load or by the opening of the pressure switch contacts.

You need to check the following nodes:

- Chimney. The passageway can be severely narrowed due to a design error, the ingress of a foreign object, or an incorrectly selected diaphragm. In this case, a restriction of the air flow will occur and the pressure switch will operate.

- Fan. It happens that it does not start at all at the start of the ignition. Then you need to check the wiring, contacts or motor. The bearing may also fail, then the fan will emit a hum, and its blades will rotate more slowly.

- Pressure switch. Contacts may come off or the device itself may break.

Error A06 - the fire goes out immediately after ignition.

There are two almost equally likely reasons for the error:

- Insufficient pressure in the gas line. It is necessary to check the shut-off equipment. If it is fully open and the pressure is poor, contact your gas supplier.

- The minimum pressure for the gas flow has been set too low. Calibration needs to be done again.

Error F07 - one of the parameters of the electronic board is set incorrectly. If the automation itself does not cope and the Ferroli gas boiler does not start, then you need to go into the menu and check the settings.

Modern models of Ferroli boilers have an advanced setting system. Sometimes the user is very addicted to modeling, which leads to system errors

Error F08 - overheating of the heating water heat exchanger (ОВ). If the temperature in the circuit is 100 ° C or higher for 5 seconds, this fact will be recorded. If it is repeated frequently, error A03 will occur. Situation F08 is not displayed on the screen and does not stop the process. However, it remains in the event register.

Error A09 - problem with the gas valve. The simplest situation is associated with a power cut. In this case, you need to check the contacts or change the wires. An open or short circuit inside the valve is also possible.

Error F10 - malfunction of the temperature sensor on the water supply to the circuit. There are 3 possible scenarios:

- Opening of contacts. Disconnect the connectors and then reconnect them firmly.

- Broken wire or short circuit. Need to ring the wire. If the problem is confirmed, it will have to be replaced.

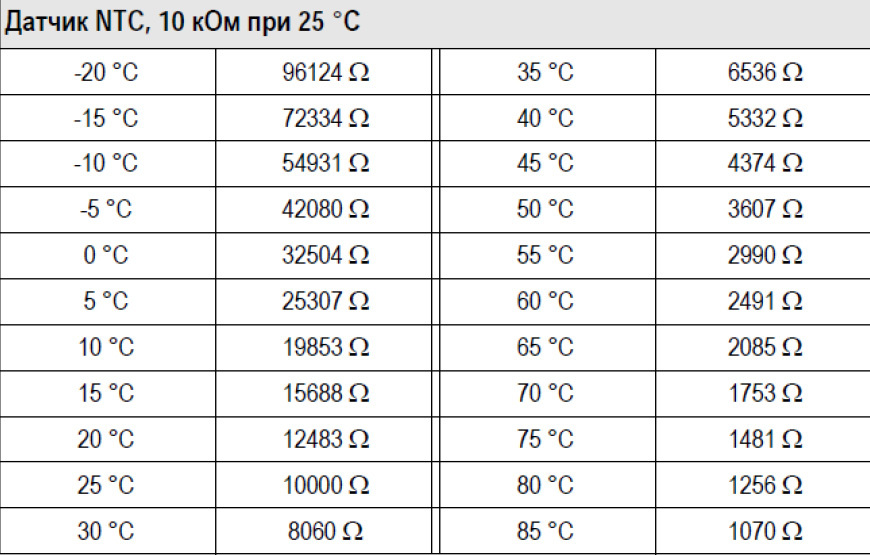

- An open circuit inside the NTC sensor itself. It needs to be removed and tested for resistance.

Error F11 - malfunction of the hot water temperature sensor. Actions are the same as for error F10. The main difference between events F10 and F11 is that in the event of a problem with DHW, the boiler will only continue to operate in heating mode. And in case of problem F10, the boiler will stop.

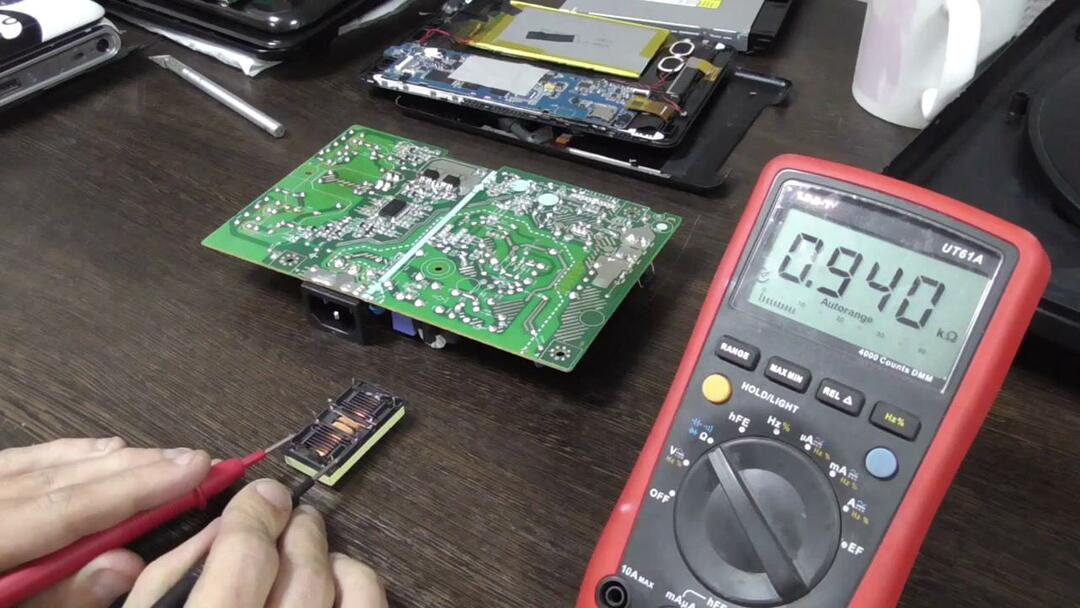

The resistance of a standard semiconductor temperature sensor (NTC) depends on its heating. Using an ordinary ohmmeter, you can determine its suitability for further work

Error F14 - malfunction of the temperature sensor at the water inlet to the heat exchanger. The situation is the same as F10.

Error A16 - problem with the gas valve. It occurs if the flame is not extinguished within 5 seconds after the command to stop the gas supply. This situation is usually caused by an electrical problem with the valve and will need to be replaced.

The most common problem that causes a gas valve to break is a break in the inductor. In this case, it is easier to make a complete replacement of the part than to look for the place of breakdown.

Error F20 - the problem is related to the general quality control of the combustion process. In this case, the boiler does not stop.

A difficult situation, since there can be many reasons for its occurrence:

- Smoke exhaust system malfunction. Proceed as in the case of errors F04 and F05.

- Malfunction or incorrect operation of the ionization electrode. You need to check the nominal gap, which should be about 3 mm, make sure the cable is in good condition and, finally, clean this part of dirt.

- Gas valve malfunction. It will have to be replaced.

- Control board malfunction. Replacement.

Error A21 - if situation F20 occurs 6 times within 10 minutes, the boiler stops.

Error F34 - insufficient mains voltage. For different models, a different threshold is provided, but usually a signal of poor current quality occurs at 170-180 V. Operation with such network parameters leads to the risk of damage to the boiler electronics.

In order to ensure the safety and durability of expensive equipment, it is necessary to take it as a rule that a gas boiler from Ferroli or another manufacturer is not included in the circuit without stabilizer. Sometimes in places where power failures occur frequently, it is advisable to install a battery system to support autonomous power supply.

The gas boiler is connected to the mains through a voltage stabilizer. If there are a lot of expensive electronics in the house, then it may be better to install an introductory stabilizer.

Error F35 - the current frequency is set incorrectly. The boiler electronics operates at a frequency of 50/60 Hz. The current value of the mains supply must be set in the menu.

Error F37 - opening of the pressure switch contacts for 5 or more seconds. If the value falls below 0.8 bar, the boiler stops.

This situation occurs in two cases:

- There was a leak coolant. You need to check the entire circuit for leaks. After eliminating the problem, the system should be charged to the desired pressure.

- The pressure sensor may fail. If so, then it will have to be replaced.

Error F39 - a problem with the outside temperature sensor. An outdoor thermometer can be connected to the boiler to provide weather-compensated heating control. However, this creates another prerequisite for a malfunction - if the signal disappears, then this error occurs.

As with all temperature sensors, you need to check the contacts, ring the wire and test the thermostat itself.

Error F40 - too high pressure in the heating system (occurs in closed circuits). You need to check the pressure. If it is really high, then it is necessary to lower it to a value of about 1.5 bar and check the operation of the safety valve. Most likely, the problem is with him.

If the pressure was normal (the exact value at which the boiler stops can be found from the operating manual), then the problem is in the sensor. It needs to be replaced.

The diaphragm tank and valve (left) are located inside the boiler. As the temperature rises, the volume of water increases, as a result, the pressure rises and the fuse is triggered, dumping the excess coolant outside the circuit

Error A41 - there is no change in the temperature of the heated water. The temperature sensor could simply move away from the pipe, or the problems described for the F10 error have occurred.

Error F42 - the difference between the readings of the water temperature sensor in the circuit and the overheating sensor is more than 12 ° C. This means that one of the devices gives a significant error, which can lead to failure (or vice versa - false triggering) of emergency mechanisms.

You can determine a faulty thermistor using an ohmmeter and a resistance table, or you can simply replace both sensors with new ones.

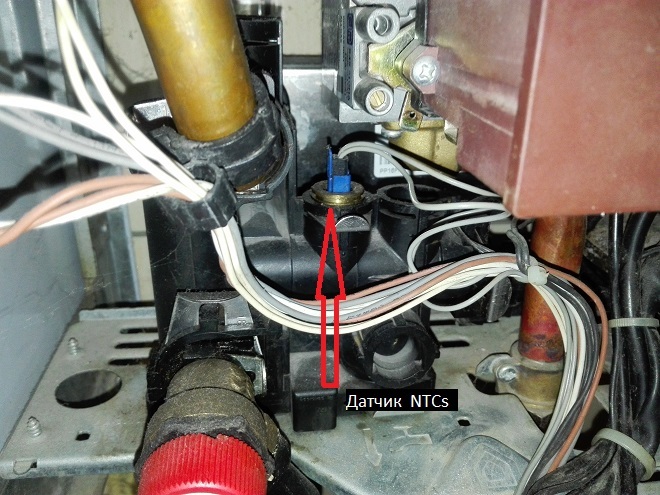

The immersion temperature sensor is fixed in the pipe by means of a thread. Its wires are connected to the control unit using a standard connector. Therefore, when replacing, you do not have to solder anything.

Error F43 - overheating of the heat exchanger. The situation can be caused by the following problems:

- The position of the shut-off valves does not correspond to the gas pressure. In this case, excessive heat is generated in the combustion chamber. It is necessary to set the correct boiler settings.

- The parameter of the permissible heating rate of the heat exchanger is underestimated. You need to check its value in the menu.

- Weak water circulation in the circuit. Causes and actions are the same as for error A03.

- Temperature sensor defective. It is necessary to check its connection or replace it.

Error F47 - no signal from the pressure switch in the heating circuit. First you need to check the contacts, then ring the signal wire from the sensor to the board. If they are ok, then the relay will have to be replaced.

Error A48 / A49 - the problem of the gas valve in the electrical part. There are two possible reasons: a breakdown of the valve itself (you need to ring its coil) or the control board. The broken part will need to be replaced.

In the case of a board, a reboot may help. If the boiler still started working after that, then you need to understand that this is a temporary solution, since the aging of the capacitors on the board has begun.

You can repair the electronics of gas boilers at computer repair centers. The main problems of boards and sensors are the same.

Error F50 - there was an open circuit of the gas valve or the current on the modulation coil was below the minimum threshold. The causes of the malfunction and the ways to solve them are the same as for error A48.

Error A51 - long period of extinction of the burner flame. The causes of the problem and the steps to fix them are the same as for error F20.

Original and compatible nodes

In the event of a breakdown of any boiler unit, if it cannot be repaired, a replacement problem arises. Ferroli equipment is not so common that you can be sure that you can quickly find the original part. However, many sensors and tubes are in a universal format, in which case it is possible to purchase products from a third party.

For Ferroli boilers, the original spare parts are as follows:

- control board;

- gas valve;

- ignition and combustion unit;

- make-up unit (tap);

- chimney fan;

- display and control knobs;

- heat exchanger (original mount);

- expansion tank.

When replacing the make-up valve, it is imperative to know the boiler model, since Ferroli has two very similar varieties of this part.

The circulation pump, safety valves, temperature and pressure sensors, pressure switch, flow switch, wiring, insulation elements, anodes can be purchased compatible. But it is important that their technical characteristics completely match.

Conclusions and useful video on the topic

An example of solving an elementary problem in the event of a boiler breakdown associated with an error in the readings of the air pressure switch. Quick repair on your own:

Cleaning the flue gas system with a vacuum cleaner:

You can repair the Ferroli gas boiler yourself if you know the type of error and how to fix it. However, it should be remembered that gas equipment is an element of increased danger. Therefore, it is better to entrust all maintenance and repair work to the representatives of the gas service with which the contract has been concluded.

In the block below you can share your own experience in cleaning and restoring the operation of gas boilers from an Italian manufacturer. It is possible that you have useful information that is worth sharing with site visitors. Share information and photos on the topic of the article, please ask questions.