The popularity of the Buderus technique is quite justified. The boilers are 100% able to cope with the tasks set, fulfill the deadline, and use fuel economically. But even the most reliable units sometimes fail for various reasons: due to wear of parts, poor-quality coolant, or due to the fault of users.

We will tell you how the maintenance and repair of Buderus gas boilers is carried out. We will show you which nodes fail more often. We will analyze in which cases you can fix the unit yourself, and in which you need to call a master from the gas service.

In the article we have proposed, you will find the decoding of the codes laid down by the manufacturer for the prompt detection of malfunctions. We have described the ways to solve problems. Our recommendations for the operation of equipment will extend the life of the boilers and reduce the number of calls to repairmen.

The content of the article:

- Gas boilers "Buderus"

-

Common faults and repair tips

- The burner does not start after service

- No spark and flame when ignited

- Ionization current problems

- Extraneous noise in the unit

- Error codes and instructions for their elimination

- Boiler maintenance recommendations

- Conclusions and useful video on the topic

Gas boilers "Buderus"

Natural gas remains the cheapest fuel, so the popularity of gas boilers is only growing. Single-circuit gas units are used in heating. Double-circuit floor or wall models easily cope with two functions necessary for a comfortable stay in a private house: heating and hot water heating.

The well-known company Bosch Thermotechnik GmbH is engaged in the production of gas household and industrial appliances of the Buderus brand. In addition to gas units, electric, solid fuel and diesel boilers are manufactured.

Buderus gas models are the largest group of heating equipment. This is due to the popularity of equipment manufactured specifically for the climatic conditions of Russia.

Boilers are diverse in design and installation method, they are single and double-circuit, with an open or closed combustion chamber.

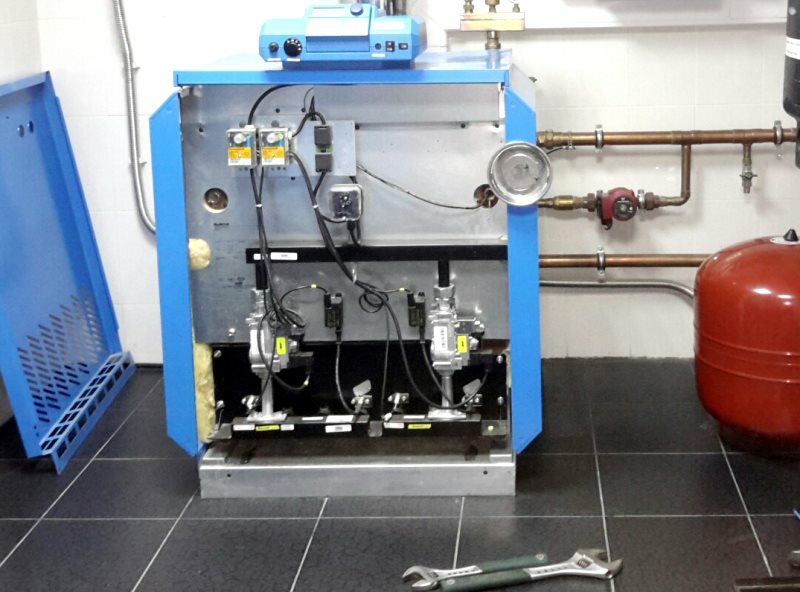

The current gas-fueled models can be divided into 4 groups:

- wall condensing;

- wall traditional;

- floor condensing;

- outdoor cast iron atmospheric.

The choice of a model according to the method of placement depends on the capacity of the unit. In apartments of the old housing stock, up to five storeys, and in country houses small in area, they use wall units. Large private buildings, commercial enterprises, production workshops are equipped by installing floor options.

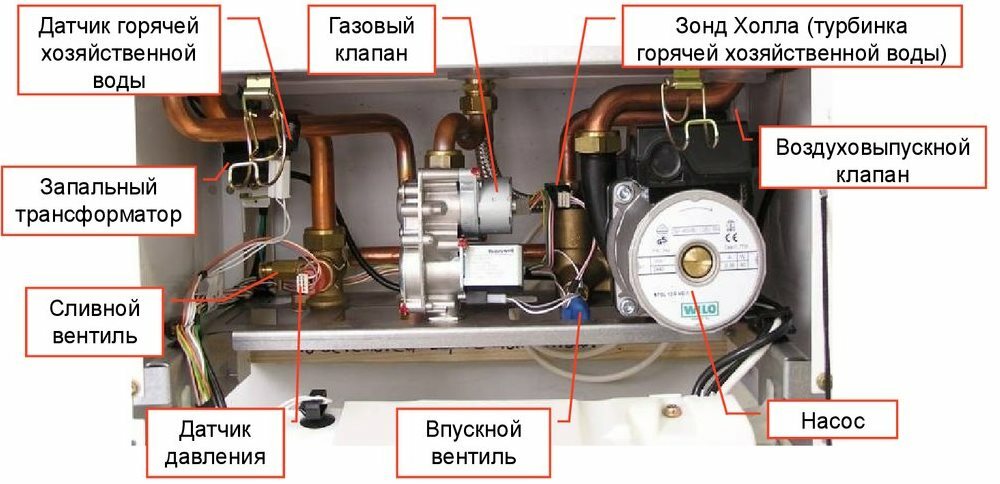

Features in the design are not fundamental, but still exist, but the malfunctions are usually the same, as are the ways to eliminate them.

For the good operation of the gas boiler, everything is important: correct installation of the unit and chimney, regular maintenance, compliance with operating rules, timely cleaning and replacement of parts, high-quality fuel.

If even one item no longer meets the requirements, breakdowns are possible. The most common ones are:

Image gallery

Photo from

Over time, poor water quality in the form of lime deposits "imprints" on the walls of the heat exchanger, which sharply decreases its ability to heat water

The reason for the malfunctioning of the burner can be both an active safety system that reacts to a breakdown, and a failure in the electronic control.

Often the display shows incorrect information about the temperature of water, air or operating mode. The reason for this is a malfunction of the sensors, which occurred due to disconnected contacts.

The control board is connected to sensors and other wiring elements and is hidden under a plastic case. But over time, it breaks down due to condensation, short circuit and other reasons.

Contamination of the heat exchanger with mineral inclusions

The burner does not ignite or goes out

Separation of contacts of wires of sensors

Failure of the electronic control board

Often, difficulties in operation arise simply due to inattention, when the user forgets to turn the gas valve or connect the electricity. Read more about breakdowns and how to fix them below.

Common faults and repair tips

A malfunction is considered typical if it can occur in a boiler of any modification - these are problems with the burner, combustion chamber, fuel supply, security system, electronics, sensors, etc.

Some problems can be solved simply - by cleaning, tightening the contacts or reinstalling the part, you can fix them yourself. If repairs require more serious repairs, we recommend contacting the service center.

The burner does not start after service

Often, after repair work, the boiler does not want to turn on, ignition does not occur, and no errors are indicated on the display.

If you decide to flush the pipeline or change the radiators, and for this you turned off the boiler and lowered coolant, then after refilling the system with water, attempts to turn on the boiler may end failure

And it's all about the emergency thermostat. We will tell you how to repair and turn on the Buderus gas boiler after a forced shutdown.

The Logamatic control unit is equipped with a safety temperature limiter STB. It is located to the left of the water regulator, under the cap. To return the limiter to the working position, you must remove the cap and press the button, then restart the unit

If after pressing nothing has changed, you need to change the overheating sensor - preferably in a service center, with a guarantee for the work performed.

There are other possible reasons for the equipment downtime.

What can be done:

- turn on the start and emergency switches;

- check the operation of the circuit breakers, in case of malfunction - replace;

- check if the combustion products control system is functioning correctly, after blocking it, restart it and wait 15 minutes.

Modern devices have a restart button. It is always recommended to use it in case of various kinds of malfunctions.

Many units do not require intervention and restart themselves. In case of repeated idle autostart, the equipment must be shown to the workers of the service workshop.

No spark and flame when ignited

If the starting process occurs in operating mode, but the flame does not appear due to the absence of a spark, you need to disconnect the ignition cable, repeat the inclusion and listen.

The absence of a sound, a kind of click, indicates a breakdown of the ignition transformer, which needs to be replaced. If there is sound, but the spark does not fly out, replace the ignition burner or electrode.

The original AE ignition device for the Buderus gas boiler. The cost of a new service kit is 8,400 rubles. To save money, you can buy a Chinese counterpart, but the quality will be lower

Perhaps the reason is elementary - they just forgot to turn off the gas tap. Open the valve and try starting again.

Air locks can also interfere with ignition. It is recommended to bleed the air from the radiators and the system through Mayevsky cranes, inspect the automatic venting device, then try again to ignite the burner.

Ionization current problems

The unit will not work if, when connecting, L and N are accidentally reversed, as well as if a voltage is established between PE and L. It is recommended to reconnect the wires and check the grounding, if necessary, install an isolation transformer.

Perhaps the point is a weak contact - during the period of operation, the terminal connections are often loosened, and the wiring falls out. Retighten all connections or replace defective element

Damage can cause a short to ground, repair the damage to the ionisation electrode. If the ionization current does not reach 1.5 mA, cleaning is required - remove any dirt from the ceramic part or the core of the ionization electrode. The pilot burner may need to be replaced.

Extraneous noise in the unit

If the boiling sound is clearly audible, it is necessary to thoroughly clean all units and parts in contact with the coolant. Usually, with regular cleaning, which is done once a year, this problem does not occur.

To a greater extent, pollution by mineral formations occurs in the heat exchanger, where hot water is constantly circulating. Scale is deposited literally on all elements of the assembly

What should be done:

- remove the cladding of the unit;

- dismantle the heat exchanger;

- descale all elements with a special agent;

- install the part in place.

In order to reduce the amount of deposits to a minimum, we recommend installing filters that reduce the concentration of salts in the water.

If water noise is heard during heating that lasts longer than programmed, the settings should be checked. Perhaps the matter is in the wrong operation of the pump - you need to check how the turbine is functioning, adjust the speed.

Error codes and instructions for their elimination

Modern gas boilers are able to inform the user about a malfunction, and fix some breakdowns on their own, by stopping and starting again.

If the unit does not cope, and an error is displayed on the display, you should act according to the instructions, and if necessary, contact the technical service

Error codes are alphanumeric characters that indicate the type of fault. Among them there are simple ones that require rebooting or cleaning, but there are also complex ones that make diagnostics of all units of the unit. Let's consider the most significant and frequently occurring errors.

0Y - temperature rise above the operating settings (at a rate of + 95 ° C). If the boiler does not turn off automatically, turn it off manually, check the health of the sensors and the adjusted settings.

You should also check the pump, connecting it to the main regulator. Adjust the pump power.

2P - a sharp increase in the DHW temperature. Check that the pressure corresponds to the operating parameters, check the operation of the pump, repair if necessary.

H11 - malfunctions with the hot water sensor. Check the operation of the temperature sensor, as well as the contacts of the connecting wires. Replace defective parts.

3A - the fan does not start. Check contacts, wire connections. If the unit is faulty, replace it.

3U - the fan speed is too high. Check the function of the flue gas duct, clean if necessary.

4C - overheating of the heat exchanger. Carefully inspect the loop and sensors, bleed the air from the system, check the pressure in the network. If everything is normal - the problem is in the water unit of the radiator or pump, disassembly and repair is required.

6A - ignition is not performed, there is no flame. Unscrew the gas valve to the maximum, check the pressure.

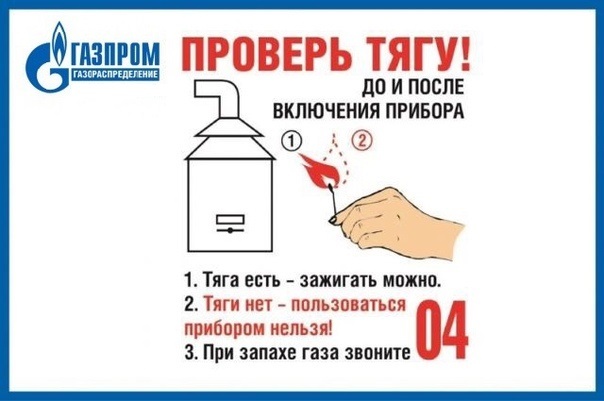

If you suspect that there is no draft, check if it is in the chimney. You can use a lighted match - an even flame indicates a dirty chimney, fluctuating - about good draft

It is also recommended to diagnose the flow switch, check and, if necessary, clean contacts of the electrodes, remove the deposits from the burners with a brush, and in case of a burner malfunction, install a new one node.

6C - the system detects a flame when the boiler is off and the gas is shut off. It should be checked that the chimney is working and that the contacts are not oxidized. Perhaps, due to condensation, moisture has appeared on the board, which needs to be dried, and at the same time check the cleanliness of the condensation siphon.

9L - malfunction of the gas fittings. A thorough check of fittings and wiring, repair and replacement is required.

After replacing some components - for example, a fan or a pump - the unit must be put into operation. After self-repairing the gas boiler, Buderus is not always able to get it to work correctly due to the "flown" settings. We advise you to call the wizard, who will check the correctness of the connection and reconfigure the unit.

Boiler maintenance recommendations

In addition to proper operation, it is necessary to regularly maintain gas equipment. According to our current rules, the rights and obligations to carry out technical inspections and repairs are transferred to the organization with which contract signed for the supply of blue minerals, installation and connection of the boiler.

The equipment manufacturer Buderus insists on the transfer of service rights to a service organization, among whose employees there are masters accredited by the company. This is dictated by the requirements of operational safety and proper maintenance of equipment.

For self-service, follow the manufacturer's recommendations.

What can you do with your own hands, without involving gas workers?

- Perform thermal disinfection - flushing the DHW system at maximum temperature.

- Clean the cladding regularly - wipe it with a damp cloth, without the use of abrasive detergents.

- Check the working pressure in the network using a pressure gauge (norm - from 1 to 2 bar).

- Add water to the heating circuit if necessary.

- Remove air from the unit if the water heating is uneven.

- Check the flue gas evacuation system and, if corroded parts are found, replace them.

Cleaning of internal components can also be done on your own. But before dismantling the boiler, make sure that the gas valve is closed and the voltage is disconnected.

Usually, such malfunctions of Buderus gas boilers, such as “sticking” of the sensor or blockage of the chimney, are dealt with on their own.

Conclusions and useful video on the topic

Boiler maintenance - disassembly and inspection sequence:

Removing and cleaning the wall model parts:

A universal option for flushing the heat exchanger:

Gas boilers Buderus, due to their power, efficient operation and maintainability, are ideal for equipping heating systems in private houses. But they, like any other serious equipment, need regular maintenance.

You can independently understand the design, characteristics and functions of the boiler, learn how to clean the heat exchanger and change spare parts, or you can conclude an agreement with a service organization. The main thing is that the unit is serviceable and safe, copes with its task and does not pose a threat to the residents of the house.

Please leave your comments in the feedback box below. Share your own experience in servicing gas boilers. It is possible that your advice will be useful to the readers of our site.