The key element of the gas heating unit is the burner nozzle. It creates a mixture of fuel and air to support combustion. If you made a gas burner for a sauna stove with your own hands, then this fact gives confidence in the reliability of the design. And this, you see, is a fairly weighty argument in favor of its own production.

You can make a nozzle for a sauna stove from scrap materials. Empty gas cylinders, scraps of metal pipes, parts from old equipment will be used. Before commissioning, the finished product is checked by Rostekhnadzor specialists.

We will tell you how to do everything correctly. We will show you how to get a certificate of suitability for a homemade gas burner. It confirms the safety of the device and allows connection to the heating system of the bath.

The content of the article:

- The principle of operation and differences of gas equipment

-

Design features and types of burners

- Atmospheric devices

- Complete set of blowing devices

- Criteria for choosing a design option

- Preparation for the manufacturing process

- Description of the stages of work

- Modernization of heating equipment

- Protective automation system

- Gas supply to the bath

- Supervisory requirements

- Conclusions and useful video on the topic

The principle of operation and differences of gas equipment

You cannot objectively judge the quality of the purchased injector. Do not disassemble the finished product in search of possible defects. So there is a chance to damage rather than check an expensive device.

By assembling each element of the burner yourself, you will receive not only pleasant satisfaction from the work done, but also savings. At the same time, the operation and repair of the gas bath equipment will become safe and conscious.

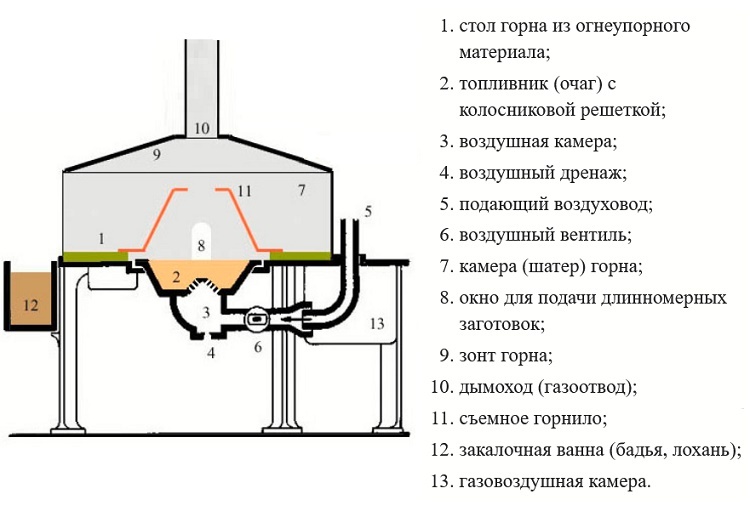

The heating gas unit is a housing sauna stove with a gas supply device located in it. The main elements of the control mechanism are located here, with the help of which the fuel supply is regulated.

The burner heats up the air in the firebox. The thermal energy of the nozzle is transferred through the body to the sump with stones

Particular attention to a heating stove with a gas nozzle requires a chimney, which must be periodically cleaned.

The advantages of heating water and bath stone with a gas burner include:

- Ease of workflow. To heat up, just turn the valve and ignite the gas in the burner. After an hour, the steam room of the bath will be sufficiently heated.

- Environmental friendliness. During the operation of the gas device, harmful emissions from the combustion of gas have the smallest volume in comparison with other types of fuel.

- Ease of maintenance of the burner and the furnace itself. There is no need to fight the soot of the walls and clean up waste, as with coal or wood.

It is possible to equip the oven with special sensors that are triggered at a critically low exhaust speed. In this case, the gas supply is automatically shut off.

Inexpensive fuel of a gasified stove allows you not to limit the number of bath procedures. Even with the daily heating of the sauna, it becomes very easy to keep clean.

Such a disadvantage of a home-made burner, such as additional registration of permissive technical documents, pays off due to its high performance. Using a gas injector saves up to 30% on costs compared to solid fuels. Heating a bath with gas is two times cheaper than using an electric boiler.

Design features and types of burners

Important parameters of a home-made gas burner are safety, ease of manufacture, suitability for work in specific conditions, and efficiency. There are quite a few options for choosing modifications of the device supplying the gas mixture. They are used for home heating, heating water boilers, even for hiking trips.

You need to navigate this diversity types of devices, in order to make a high-quality burner for a bath with your own hands.

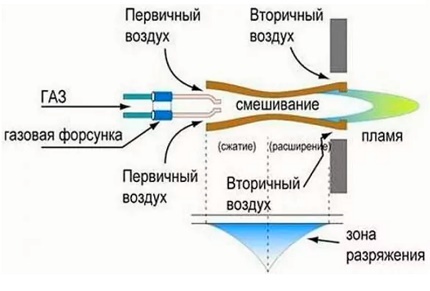

By the way air enters the burner, they are conventionally divided into two types:

- Atmospheric, with natural air supply to the combustion zone.

- Fan, with forced air supply, carried out by a built-in fan. They are blown and supercharged.

For self-production, atmospheric burners are more popular among craftsmen. The simple design of the nozzle can be improved with additional options. For example, equip the burner with a thermostat, draft sensors, flame control, a gas shut-off valve.

Consideration should be given to the physical parameters of both the sauna stove and the selected nozzle model. Before starting the manufacture of the burner, determine the dimensions

All these functions will increase the reliability and safety of work, but at the same time will increase the value of your product. It is up to you to decide how expedient the additional equipment is, based on the financial possibilities and the frequency of the burner operation.

Atmospheric devices

Such burners are one or more hollow metal tubes through which gas fuel is supplied under pressure. Ignition is carried out using a piezo lighter. Atmospheric nozzles are the cheapest and easiest to manufacture.

Usually do-it-yourself atmospheric gas burners. Their advantages are independence from electricity and pressure drop in the gas main.

The main disadvantage of atmospheric gas burners is considered to be the need for a constant high-quality air flow. It will have to be equipped additionally in the bath. Usually, an ash pan or an air duct connected to it is used for this purpose.

An efficient ventilation pipe with air intake from the adjacent room. At a low draft level, most of the poorly burned fuel goes into the chimney. This threatens the danger of gas leakage if there are microcracks in the brick mass.

Therefore, a brick stove with such a burner needs constant inspection and control of the state of both the furnace array itself with smoke flows and the chimney.

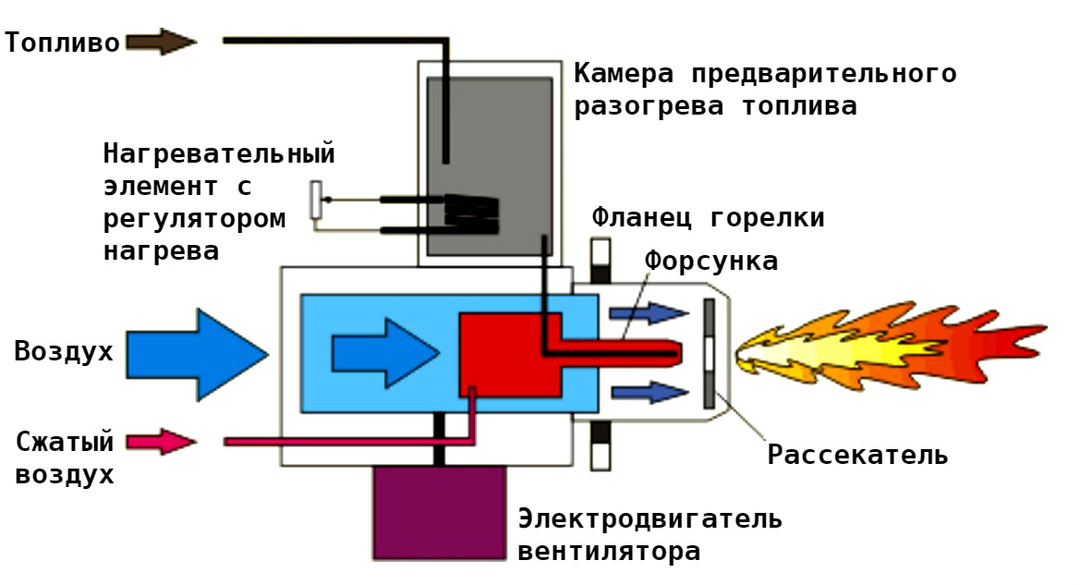

Complete set of blowing devices

Fan burners are a unit with a fan, sensors and controllers. Air intake and injection from the street is carried out automatically, the operation of the equipment is controlled by automatic equipment. The combustion power in the blowing device can be adjusted according to needs.

Forced uninterrupted supply of air allows you to increase the efficiency of the heating device, due to the high-quality combustion of gas. Accordingly, the fuel consumption for heating the sauna stove is reduced.

A fan burner is more difficult to install, but easier to operate. The intensity of the nozzle in such a scheme is easier to regulate with the help of automation.

The cost of the equipment is affected by the connection of the burner to electricity. In case of possible power outages, it is necessary to have an alternative source, for example, a diesel generator or a battery.

Both types of gas burners can be converted from liquefied gas to main gas and vice versa. For the transfer, the jets are replaced, due to which the volume of the gas mixture injected into the combustion chamber changes. Replacement nozzles are selected in accordance with the manufacturer's recommendations, more precisely with the dimensions indicated by him.

Criteria for choosing a design option

Each type of burner has its own parameters of power and gas consumption. A volatile inflatable burner with more expensive accessories is used for a large-volume bath heating boiler.

To heat small and rarely used rooms, the installation of an atmospheric burner is recommended. A bathhouse of modest size is enough for a model with a flow rate of 1.5-4.5 m3 in hour.

To maintain a comfortable temperature in the bath, a burner with a uniform flame distribution is needed. This problem is solved by all kinds of distributing tubes or torch splitters. They are usually round holes. But sometimes the format is changed to narrow slots, such nozzles are called slotted nozzles.

A slotted gas burner demonstrates the difference in the physical parameters of the fire when the external shape of the holes changes. This slight difference in burner design significantly affects the overall flame pattern.

For any selected type of burner, it is preferable to make a branch with a long elongated shape. This will accelerate the heating of the furnace by increasing the area of the flame. After all, gas heating is allowed to be used only from a room adjacent to the steam room.

Preparation for the manufacturing process

Having dealt with gas burner device and having decided on the model, you can proceed to the next preparatory stage. Make a list of the materials and tools you need.

The following list can be taken as a basis:

- steel tube 100 mm long and 2 mm thick walls;

- fuel supply control valve;

- steel cap, piezoelectric element, rubber for the handle;

- welding machine, grinder.

Don't forget about the little things like connectors. For example, for a valve of the VK-74 type, you need to stock up on a cap with a tapered thread.

Description of the stages of work

Before starting the assembly of the burner parts, it is better to have a drawn diagram on hand for convenience.

Self-manufacturing technology provides the following sequence:

- the basis of the device, the nozzle is made using a grinder;

- the fuel dispenser is assembled from the valve and a steel cap screwed onto it;

- a cap is welded to the nozzle, then a piezoelectric element is installed.

When installing a burner assembled and tested by specialists, the distance limitation must be observed. It should be no more than 5 meters from the gas nozzle to the end of the chimney pipe.

Modernization of heating equipment

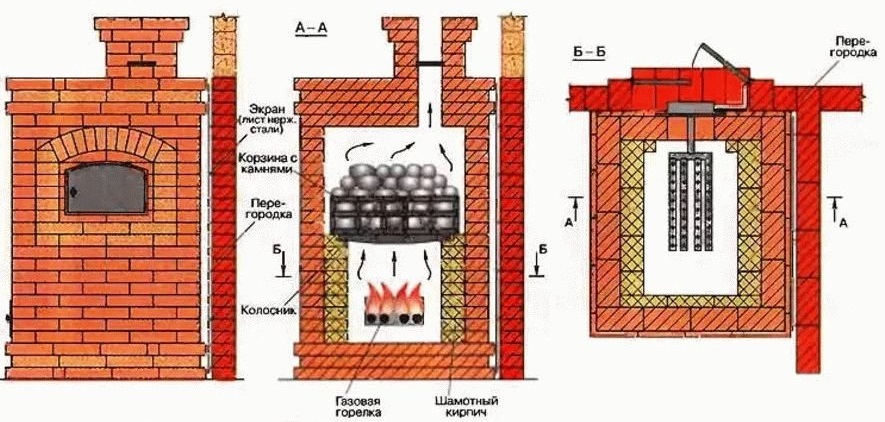

Installing a homemade atmospheric-type gas burner for a sauna stove is within the power of any home craftsman. So, without special costs, a solid fuel boiler can be converted into a gas one.

Equipment existing in the bath solid fuel furnace prefabricated gas burner block will require some adjustment. You will be faced with the need to modify the dimensions of both the burner and the combustion chamber of the wood-burning stove.

Re-equipment of a solid fuel sauna stove into a combined gas-water stove is quite within your power, but it will require precision and some effort. The flame must not be allowed to come into contact with the walls of the furnace.

For uniform heating of the furnace chamber, place the burner closer to the bottom of the furnace and strictly in the center. It is unacceptable to place the source high and offset in any direction. In this case, the camera will not fully warm up. And the flame from the burner can touch metal parts or the stove of a sauna stove.

Protective automation system

Unburned fuel in a sauna stove sometimes causes an explosion of the gas-air mixture. Therefore, it is necessary to monitor the flame of a working nozzle for your safety. This can be done visually or with the help of automation with modern photocells sensitive to light emission.

The burner protection system automatically provides the following functions:

- power regulation;

- fuel and air supply;

- completeness of gas combustion.

It is necessary to take into account the increase in the dimensions of the modernized structure. Especially when the size of the bathhouse is small. If the size of the device is an important criterion for you, then for compactness, the entire automation can be placed outside.

You can add automatic schemes for working with simple elements. Compact placement will save the useful area of a small bath

To control the combustion process, you can use an automatic factory-made installation of the SABK-8-50S type. It provides a high level of security thanks to four levels of protection. The operation of gas stove equipment with such a device will automatically stop in the event of a dangerous emergency mode.

Gas supply to the bath

Sauna stoves with gas nozzles have become a technological breakthrough for people living far from forests. Considering the low cost of gas fuel in comparison with wood, the cost of heating with a burner becomes quite negligible.

Lovers of a steam room can not limit themselves and use such a bath every day. Only, of course, if health permits.

Uninterrupted supply of gas fuel to the sauna stove can be provided from:

- Backbone network, laid to the suburban area and connected to the bath.

- Gas cylinders, refueling of which is required to be periodically performed.

- Gas holderinstalled on the site, stationary or in a mobile version, suitable for periodic refueling.

The most time-consuming procedure will be cutting into the general gas systemsnear a city or rural settlement. It requires the purchase, installation and registration of gas meters. You will also need the registration of permits, technical and payment documentation.

A gas pipeline in the area with a bath facilitates the task of supplying fuel. It will not be difficult to solve technical issues with the connection of a reliable gas burner

Connecting regular gas bottle will also require an invitation from a gas service representative and the preparation of technical documentation. Tanks have special placement requirements.

For example, gas cylinders cannot be installed in the bathhouse. They should be located outside in an easily accessible ventilated place. There must be fire-fighting protective equipment nearby - a fire extinguisher, sand.

Supervisory requirements

A self-made sauna stove burner must have a certificate of suitability from Rostekhnadzor. In addition, you need a special permit for operation. When using main gas as fuel, you need to draw up such a document with the gas supplying organization.

The following requirements are imposed on the installation of an atmospheric model in a bath:

- minimum bath volume 12 m3;

- the presence of good ventilation;

- compliance with fire safety measures;

- the top of the pipe is equipped with a spark arrestor;

- good adjustable traction;

- the pipe is insulated from the ceiling and roof.

The cylinders can be placed in a special metal cabinet separate from the bath. Gas holders located in an underground container at a distance of more than 5 meters from the bath. The connecting pipes must be checked for leaks by a specialist. They are made of steel, copper and other non-combustible materials.

Special requirements are made by fire officials to the pipeline to the furnace, to the places where the cylinders are installed. Those who ignore the rules are likely to get a fine, which will reduce all savings to a minus

As practice shows, it is better not to install a homemade burner without the permission of the authorized bodies. It is too risky in terms of security.

Having received a permit for operation and all instructions, you should ensure that measures are taken to comply with the normal operation of a homemade sauna stove burner. It is necessary to periodically check the tightness of the joints of the burner and the pipeline. If necessary, clean the chimney and reinforce the insulation.

Inspection of the condition of the equipment is not limited to the gas burner. It is important to observe the insulation of the chimney from the ceiling and roof slabs.

To track the dynamics of changes in the state of the equipment, keep a special log. Record in it the dates and operations performed on the maintenance of the elements of the gas unit. When heating a bath with a homemade nozzle, follow normal fire safety rules.

Introduce the intricacies of making a gas burner from a conventional blowtorch next article, which is worth reading for skilled home craftsmen.

Conclusions and useful video on the topic

Demonstration of the operation of a simple home-made burner in a wood-burning sauna stove using a gas cylinder:

A gas burner with automatic control, which requires an advanced level of craftsman in its own manufacture:

Prefabricated furnace automation SABK for gas burners supplied with fuel from a main or stationary source:

It is not difficult to make the simplest gas burner for a sauna stove with your own hands, which will serve you for many years. Take the time to check the reliability of the structure. Observe the rules for installing and storing autonomous sources of gas fuel.

Installation of a burner with automatic elements to control the combustion process and safety shutdown of abnormal modes will require certain knowledge and skills. If you are not confident in your own abilities, it is better to purchase a finished product.

Have you already made a gas burner and installed it in a sauna stove? Do you have practical experience in heating a bath with homemade products and issuing permits, connecting the burner to the main gas network? Share it, tell us about the important points, post your comment and photo below.