It's no secret that gas distribution systems in settlements, as well as in apartment buildings and private houses, are a source of constant danger. The slightest leak of blue fuel can lead to serious problems, up to and including an explosion. And you must agree that this does not happen, it is extremely important to carefully and constantly monitor the condition of the gas pipes and fittings on them.

One of the main shut-off elements here is a gate valve or tap, which, if necessary, turn off the gas in the pipe. And in order for these disconnecting devices on gas pipelines to work properly, their selection and installation should be approached with full attention. Next, we will analyze all types of such equipment and the rules for its installation.

The content of the article:

-

Types of gas shut-off devices

- Option # 1 - Wedge Gate Valves

- Option # 2 - plug valves

- Option # 3 - odor traps

- Placement of shut-off valves on the pipe

- Conclusions and useful video on the topic

Types of gas shut-off devices

Fittings for gas pipelines are: shut-off, safety, emergency and reverse action. To turn off the gas manually, the first version of the devices under consideration is used.

They are installed on pipes in order, if necessary, to quickly shut it off and stop the supply of methane or propane in one or another section of the gas pipeline.

It is prohibited to use water taps, valves and valves to shut off natural gas. The considered disconnecting devices must be designed for operation with a gas environment and liquefied hydrocarbons.

Shut-off valves on gas pipelines are installed in the form:

- gate valves;

- cranes;

- hydraulic locks;

- valves.

Each of these options is designed for its section and type of gas pipeline. For example, valves, taps or water locks are installed on low-pressure gas pipelines, and high pressure - mainly valves only. And valves are rarely used in general.

Shut-off valves are also divided into devices:

- manual;

- automatic high-speed.

The former are usually used where the pipe shut-off speed is not very relevant. And the second ones with a magnetic or pneumatic drive are designed to quickly close the gas in case of accidents and identify leaks.

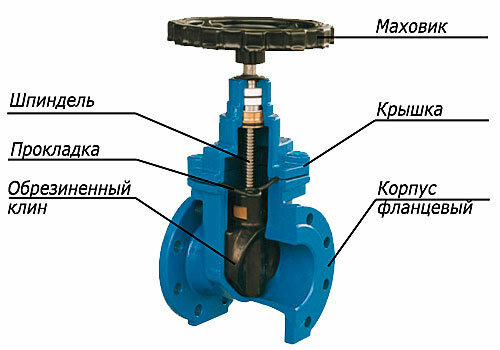

Option # 1 - Wedge Gate Valves

The most common shut-off devices in the case of gas pipelines are gate valves with a gate that moves inside them parallel to the flow of the working medium. They consist of a body, a cover with a valve, a spindle and an internal wedge-shaped shutter.

Wedge valves are used on internal and external gas pipelines, therefore they are produced with DN 25, 50, 150, 350 and 600

Wedge gate valves are divided into two types:

- With non-rising spindle.

- With a rising stem.

The first version of these disconnecting devices is intended for installation on underground gas pipelines in special wells. It is smaller in size and is usually equipped with an electric drive for remote control of the gas flow in the line.

The second option is more durable and easier to operate. The rising spindle is not exposed to the working environment and lasts longer. Plus, the entire screw mechanism in this device is visible and available for repair.

Among the advantages of valves:

- the utmost simplicity of the locking device;

- low hydraulic resistance;

- small dimensions in height and length.

Their main disadvantage is a decrease in the tightness of the valve when the seals are clogged and / or worn out.

The retractable stem is more practical and durable, but when fully opened, the valve rises high above it and takes up a lot of space

If the gas pipeline has a working pressure of up to 6 kgf / cm2, then the wedge gate valves on it are installed from gray cast iron. And if the pressure inside is more than 6 kgf / cm2, then analogs of steel or ductile iron are used.

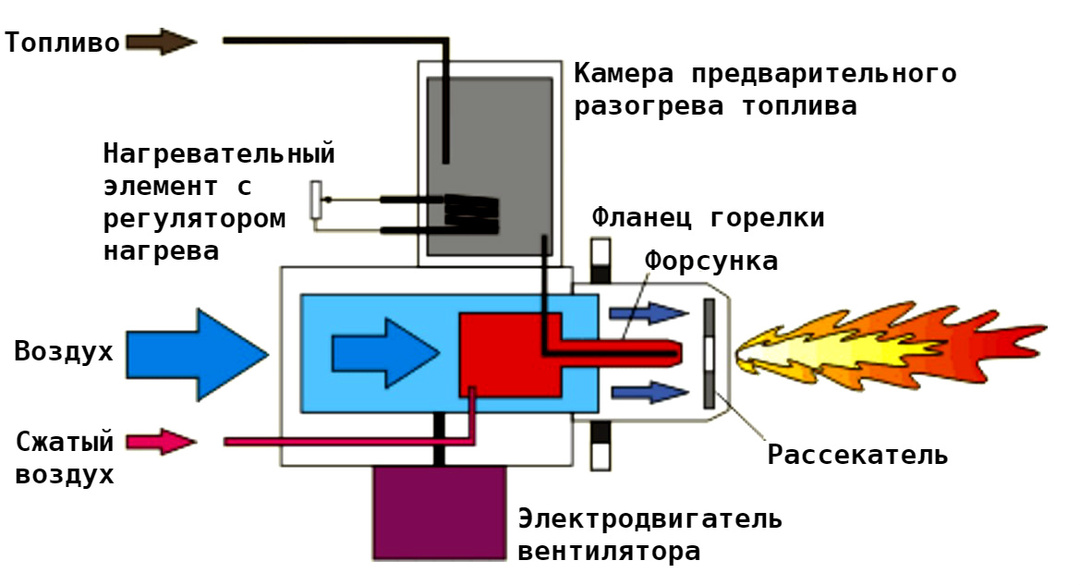

Option # 2 - plug valves

The cranes have inside a metal plug revolving around its axis, which is tightly ground to the socket. When opening the disconnecting device with the handle 900 relative to the gas flow, the plug does not prevent its passage through the valve, but when closed, it completely blocks the pipe.

Cork valves are made from:

- brass;

- bronze;

- gray cast iron;

- become.

For internal gas pipelines and for turning off / on gas appliances, it is recommended to take brass or bronze taps. Due to their high resistance to mechanical stress and increased anti-corrosion characteristics, they will last much longer than other options.

If a gas pipeline with a diameter of more than 25 mm, then cast iron taps are usually installed on it, since they are cheaper. And in systems with high pressure, devices made of steel are already used.

The highest quality gas pipeline valves are made of bronze or brass. They are expensive, but very durable and practically exclude the appearance of sparks when striking the reinforcement of a metal object.

Among the advantages of shut-off valves:

- small hydraulic resistance;

- small overall dimensions;

- the ability to connect an electric drive for automation;

- speed of opening / closing (just turn 900 pen);

- simplicity of the device.

At the same time, these valves are characterized by low tightness when closed at high gas pressure in the pipes. Plus, with poor lubrication, the plug often "sticks" to the body. And in order to tear it off, you have to make serious efforts, which negatively affects the service life of the fittings.

By the method of connection, taps are distinguished by flanged, pinned and threaded (coupling). Moreover, the latter are forbidden by GOSTs to be installed on underground gas pipelines, since they can provoke a gas leak.

There are also ball valves. They are produced in DHave from 50 to 1400 and are intended for main pipelines. In intra-house networks, they are rarely used due to their high cost and more complex design.

Option # 3 - odor traps

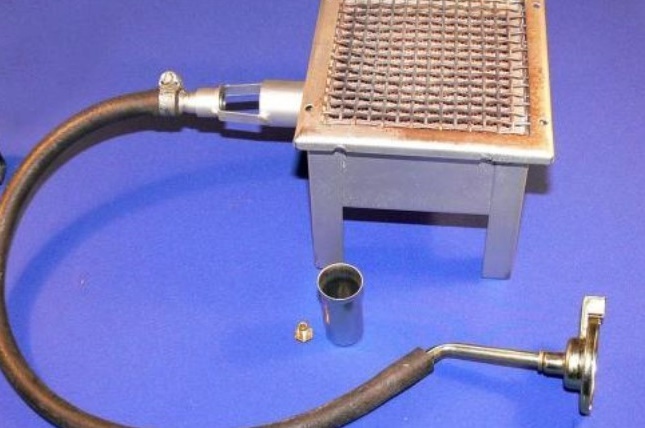

In the hydraulic seals, ordinary water is used as a shut-off element. These fittings are designed for installation on low-pressure underground gas pipelines and exclusively below the freezing level of the soil. It is highly reliable, but difficult to maintain.

Unlike gate valves, hydraulic locks can be mounted directly on the pipeline without a well.

Water locks are usually installed at the branches from the central highway to some object and at the entrances to the building. They are durable and very reliable. However, such fittings allow only to completely shut off the gas, and not to regulate its flow.

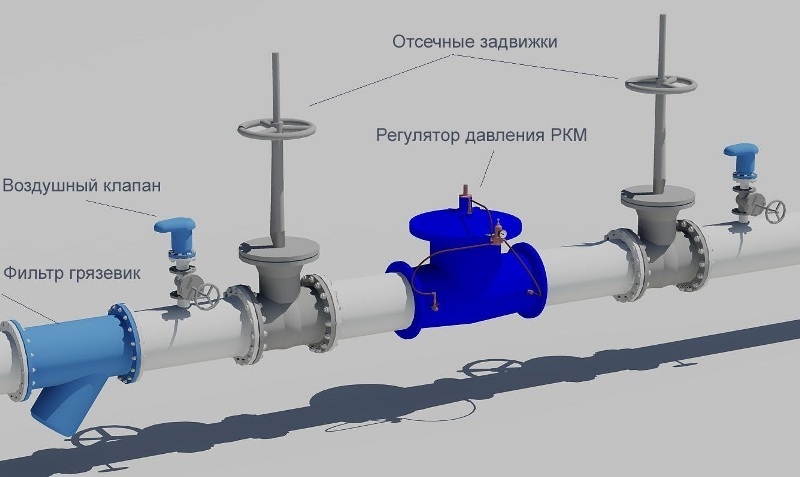

Placement of shut-off valves on the pipe

Before installation in the gas pipeline system, valves and valves are subject to external revision, lubrication, gaskets and tightness tests. In this case, the place for installing the disconnecting device on the gas pipeline is selected in accordance with the recommendations SP 42-101-2003.

Installation of disconnecting devices on a gas pipeline is carried out underground - in a well or directly in the ground or above ground - in fireproof cabinets, on walls or pipes.

The installation of shut-off valves is carried out so that it can be inspected, serviced and, if necessary, dismantled.

The place for inserting the disconnecting device into the gas pipeline is selected:

- on branches from the main - outside the territory of the consumer and no further than 100 m from the distribution pipeline;

- in the presence of parallel pipes - at a distance convenient for servicing both devices;

- at the outputs and inputs of hydraulic fracturing - at a distance of 5–100 meters from the point;

- when a gas pipeline crosses an overhead power transmission line - outside its security zone;

- on the walls of private houses - at least half a meter from door and window openings;

- near the gas stove - on the side of the pipe at the level of the connecting pipe at a distance of 20 cm or more from the tile;

- at a gas stove or a column with an upper wiring - at a height of 1.5 above the floor.

If the reinforcement is installed at a height of more than 2.2 m, then a metal ladder and / or a platform at this level must be provided.

If wells are being installed, then they should be made from non-combustible building materials. Stone, brick, concrete, etc. will do. But no wood or plastic.

For indoor and outdoor outdoor gas pipelines with steel and polyethylene pipes used for natural gas and LPG in the vapor phase with a pressure of up to 0.005 MPa, conventional ball valves are recommended type

The flange connections should be sealed with the following gaskets from:

- paronite - at a pressure of up to 1.6 MPa;

- oil and petrol resistant rubber - at a pressure of up to 0.6 MPa;

- aluminum - at any pressure;

- copper - at any pressure (except for gas pipelines with sulfur dioxide);

- high and low density polyethylene, fluoroplastic - at pressures up to 0.6 MPa.

It is worth noting that flange connections of rectangular and square type are quite difficult to process and difficult ensure reliable tightness of the connection, therefore it is better to give preference to flange connections of a round forms.

Disconnecting devices must be installed:

- at the entrance to the building;

- before an outdoor unit consuming gas;

- at the inlet and outlet of hydraulic fracturing;

- on long dead-end bends;

- on branches from a common highway to a village, quarter or enterprise;

- when the pipeline crosses railways and highways, as well as water obstacles.

All installed slewing cranes must have a handle rotation limiter 900, and the gate valves are an indicator of the degree of opening.

And all devices with a diameter of up to 80 mm must have a risk on the case indicating the direction of the gas flow.

Conclusions and useful video on the topic

Control and shut-off valves operation technology:

Film about shut-off devices for gas pipelines:

Gas shut-off valves differ in design, material of manufacture and type of connection. It is recommended to install ordinary plug valves on internal gas pipelines, and water locks and valves are more suitable for large-diameter main pipes. The place for the installation of such devices is selected in accordance with the general rules for the design and construction of gas distribution systems.

You can leave a comment on this material, ask a question to experts or participate in the discussion - the contact form is located under the article.