Cooking food, alas, takes a lot of time and effort. Often, the duration of cooking depends not so much on the complexity of the dish as on the power of the gas stove: on a nominally weak technique, everything is cooked and fried longer. Finding ways to increase the power of a gas burner is so relevant because spending a free evening on yourself is much more pleasant than standing at the stove.

But are these modernization methods really safe? And is playing with gas worth saving time? We will consider these burning issues in detail in this material, providing it with visual photos and useful videos.

The content of the article:

- Briefly about the power of the burners and the stove

- Gas stove burner device

-

Ways to increase the power of the hotplate

- Method # 1 - boring or replacing the jet

- Method # 2 - reducing the length of the jet-mixer

- Method # 3 - removing the splitter

- Method # 4 - increasing the gas pressure

- Why does the hotplate burn poorly?

- Regulating the flame in the hob burners

- Conclusions and useful video on the topic

Briefly about the power of the burners and the stove

The total power of the working surface depends on the number of burners and their direct power indicated in the equipment passport. The average for one burner is 2-2.5 kW. With a decent gas quality and normal pressure in the line, this value is quite enough for a comfortable and relatively fast heat treatment of products. In this case, the maximum power of the burner is determined by turning the knob to the limit and full gas supply.

Manufacturers often offer household hobs with different power ratings:

- on small - 0.7-1.2 kW;

- on medium - 1.3-1.8 kW;

- on large - up to 4 kW and more.

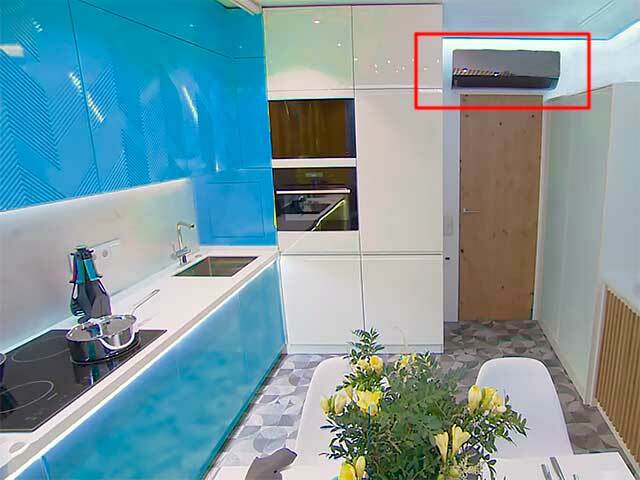

Such a technological solution is quite logical and convenient: it makes no sense to brew coffee in a Turk on a powerful WOK burner or try to boil a large volume of water on a small one. The choice of different capacities allows you to save gas, and if the room temperature is maintained using air conditionerthen save also electricity.

When using powerful burners, the air heats up more due to heat transfer, so climate technology will need more resources for cooling

Thus, the acceptable parameters of the calorific value of the gas used by the hob from the middle price segment, consisting of 4 burners, is 8-10 kW. More budget models usually have a total power of 5-7 kW.

For normal safe operation, hobs with a high calorific value may require a separate chimney or the installation of a heavy-duty hood. However, for home conditions, the purchase of such models is not always inappropriate.

Gas stoves with two- and three-circuit burners are especially popular. The so-called double or triple "crown" is a powerful burner in which the flame is emitted not in one row, but in several circles. Such a device allows you to cook faster and heat the dishes more evenly.

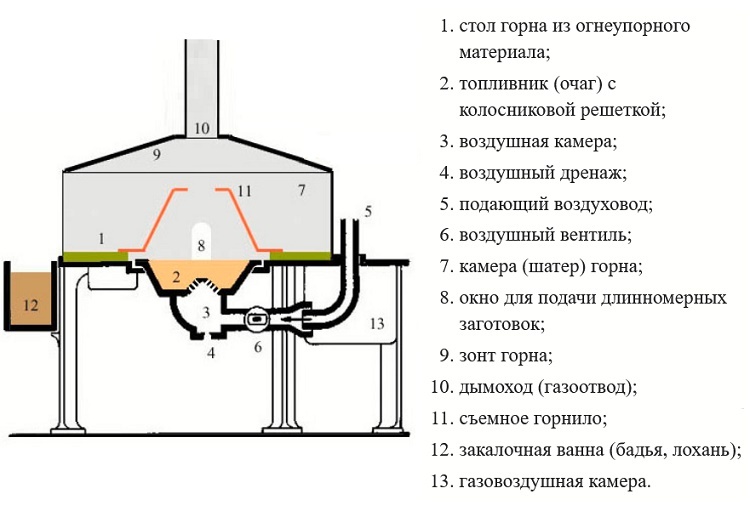

Gas stove burner device

To understand how you can increase the flame in a household gas stove, you should familiarize yourself with the structure of the burner itself, the principle of supplying and burning gas.

The first thing that is worth remembering once and for all: not just pure gas is burning in the stove, but a gas-air mixture. It is from its final composition, the ratio of gas and air that the size and efficiency of the fire that the consumer receives from the burner largely depends.

Evidence that the optimal amount of air is mixed into the gas is the blue color, the absence of soot and obvious yellow "flies"

Burners in the burners, depending on the method of air intake, are of three types:

- Diffusion commonly used in ovens. Air leaks in such structures are absent, mixing with gas occurs naturally.

- Kinetic burners use gas line pressure to trap the right amount of air to create a suitable fuel mixture.

- Combined burners successfully use both methods of adding air to gas. It is these devices that are used in most household gas stoves.

The design of the burner itself has a simple, but precisely verified configuration.

The pipeline ends with a tip, into which the jet is mounted. Its passage hole has a certain calculated diameter. It is through it that gas is supplied to the mixer, in which the fuel is mixed with air. From the mixer, the combustible composition enters the burner, in which a flame is produced.

The diagram shows a gas burner device. The construction seems simple only at first glance. However, a failure in any node can affect the quality and composition of the gas-air mixture and reduce the efficiency of the stove.

It is worth focusing on the area between the nozzle and the mixer. While the gas overcomes this distance, exactly the amount of air is added to it, which is necessary to obtain the optimal combination of fuel and oxygen. This distance is also strictly calculated, so that the gas is burned completely and with the greatest possible efficiency.

Ways to increase the power of the hotplate

Based on the design features of the burner, several methods of increasing the power of the stove are popular. But is it appropriate to test them on your own experience?

It is worth recalling that even self-repair of gas appliances is prohibited, and even modifying equipment at home is an undertaking bordering on dangerous and even deadly sabotage.

A common cause of emergency gas leakage is most often the negligence of users towards home equipment. The ending of such incidents often becomes tragic.

Unfortunately, explosions and carbon monoxide poisoning - tragedies that shock the public with the frequency and number of victims. Therefore, it is definitely not worth redoing the design of the burner for the sake of your own convenience. And the methods described below are more useful for understanding theory than for practical application.

Method # 1 - boring or replacing the jet

The orifice orifice is one of the main regulators of the gas volume, which gradually enters the burner. To increase the power of the hotplate, you need to carefully bore the jet or replace it with a part with a wider feed opening.

For boring, you can use a sharp knitting needle with a diameter of up to 3 mm. But you should not get too carried away - uncontrolled enlargement of the hole or replacement of the jet are fraught with extremely unpleasant consequences.

It is impossible to increase the flow of gas without miscalculations, since the burner itself must be able to process it. Excessive gas will cause the flame to separate from the burner. The fire will change color to red, soot will appear, which is almost impossible to remove from the dishes. The problem can be solved by installing a larger diameter burner.

In fact, the boring of the nozzle leads to the creation of an emergency and fire hazardous situation. The ephemeral ability to increase the power of the burner is almost guaranteed to lead to undesirable consequences

However, replacement of the burner is not always possible due to the design of the stove body itself. Even if you actually replace the burner, the new volume of gas transmitted through the nozzle may not be enough. This threatens even greater problems: the flame can slip down and burn out near the nozzle itself.

But dull flame and soot in this case are the lesser of evils. A drop in the flame indicates incomplete combustion of the gas, in which combustion products dangerous to life and health are released - soot and carbon dioxide.

Method # 2 - reducing the length of the jet-mixer

Fortunately, this method is less popular with advice on how to try increasing the power of your gas stove. The method is more dangerous than the previous one, since it involves even more interference with the design of the burner, is less effective and can also lead to negative consequences.

The size of the area on which attention is focused in the description of the burner device also affects the power of the flame produced. If you reduce this zone, gas will enter the burner faster, and the power of the burner will slightly increase.

However, the portion of air necessary for normal combustion will simply not have time to mix into the incoming gas. As a result, the modernizer will receive the same red flame with soot, which will most likely come off the burner.

The gas burner is an important and clearly calculated unit by engineers, where every detail has optimal characteristics and is in its place

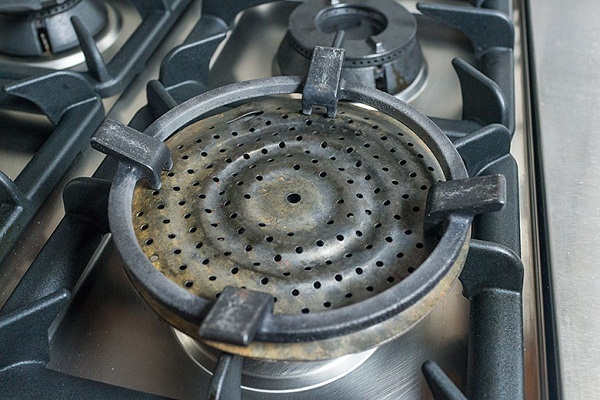

Method # 3 - removing the splitter

It is possible to try to increase the burner power without affecting the operation of the jet. The splitter covering the burner evenly divides the flow of the gas-air mixture, distributing the flame into separate bundles. Removing the diffuser increases the contact area between the flame and the cookware. The pillar of fire becomes higher and larger, and the heat treatment itself is faster.

However, this is an extremely temporary measure and is not suitable for every saucepan. For this kind of cooking, you need to use tall cauldrons or special WOK pans. Additionally, fire uncontrolled by the divider becomes quite dangerous.

It will also be useful to regularly clean the holes in the divider, which can become clogged with combustion products or burnt food residues.

Method # 4 - increasing the gas pressure

The pressure boosting method is only suitable for slabs connected to gas cylinders. The standard cylinder pressure for domestic use is about 1.6 MPa. But this value is not constant: the force of gas pressure on the walls of the vessel can be influenced by both the degree of filling of the cylinder itself and the temperature in the room, the composition of the gas, etc.

The higher the gas temperature, the more it expands, pressing against the walls of the container. Therefore, the cylinders are not completely filled, but approximately 85%. And, the less gas remains in the vessel, the weaker its flow to the burner.

It is necessary to try to increase the pressure of the gas entering the stove using reducer, the so-called "frog". It is not safe to tamper with the assembly and, fortunately, most modern gearboxes are non-separable. However, replacing the part may solve the problem. The supply of gas with increased pressure will provoke more air leakage, due to which the flame on the burner will increase significantly.

But do not forget about safety precautions and monitor the gas supply even with the burner regulator closed. Too high pressure can cause gas to be etched even when the burners are not switched on.

The cylinder is an important element of the gas system. Gas tanks must undergo periodic verification and maintenance, during which the tightness of the seam will be checked, if necessary, the valve will be replaced

Based on all of the above, you can understand that when choosing one of the ways to increase power, you should be extremely careful and not overdo it.

The only safe and affordable way to increase the power of the burners is to buy a new hob or stove. It is necessary to initially select gas equipment that meets the needs of the family. Any attempts to change the passport parameters of the burners by an inexperienced master at home will inevitably lead to serious problems.

Why does the hotplate burn poorly?

If, according to the passport, the burner has more power, but in fact does not produce the required amount of flame, it is worth looking for possible reasons for the decrease in the efficiency of the equipment.

The most common reasons for poor burning are the following:

- line pressure too low;

- the air-gas mixture enters the burner in an insufficient volume;

- the holes in the "crown" or jet are clogged with combustion products;

- the design of the burner is broken or the gas hose itself is damaged;

- the burner does not match the set cooking zone.

The latter option is rather an exception to the rule, since all hobs are thoroughly tested at the manufacturing plants. Equipment diagnostics and repairs must be carried out exclusively by a certified technician. gas service.

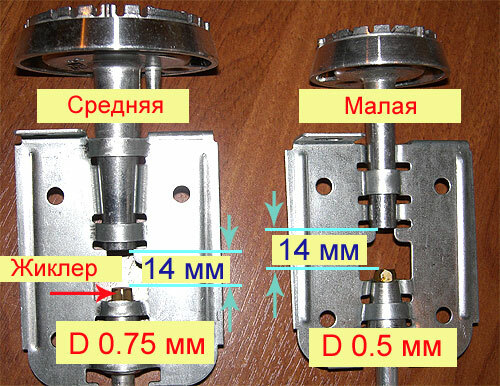

Another reason for the improper operation of the burners can be an unsuitable jet. Many gas stoves are supplied with two types of these nozzles, each of which is suitable for a specific type of gas: cylinder or main.

The difference in the diameter of the throughput in the jets for different purposes plays a huge role in the actual power of the burner.

The gas pressure in the cylinder is significantly higher than in the pipeline, therefore, jets with a narrower opening are used to connect the plate.

Perhaps when installing and hob connection the centralized gas supply pipe was not replaced with nozzles of the required type, therefore the burner does not work correctly.

Regulating the flame in the hob burners

It is necessary to debug the normal operation of the burner in cases where the flame loses its efficiency and quality. A specialist should also be engaged in setting up a gas stove. But understanding the algorithm of this process will be useful for any user.

To begin with, it is worth understanding what a properly burning stove flame looks like. The fire should be blue. An intense bright blue glow is a sure sign that the cooker is working correctly and does not need to be debugged. A yellow, orange, or red flame indicates an incorrect composition of the combustible mixture. In this case, there is clearly not enough air, its inflow must be increased.

Sparks and flames are another sign of insufficient air in the burner mix. Correction of the composition takes place by working with a special screw

To change the gas-air mixture entering the burner, it is necessary to adjust the operation of the air dampers, which are usually located near each burner.

The direct setting is as follows:

- after disconnecting the stove from the gas system, it is necessary to gain access to the adjusting mechanisms under a special partition or in the gas regulator knob;

- the stove is reconnected to the mains, gas is alternately supplied to each burner;

- the volume of air entering the mixer is adjusted by turning a special screw;

- as soon as the flame in each burner acquires the correct color, you can turn off the stove again, reassemble it and connect it to the mains.

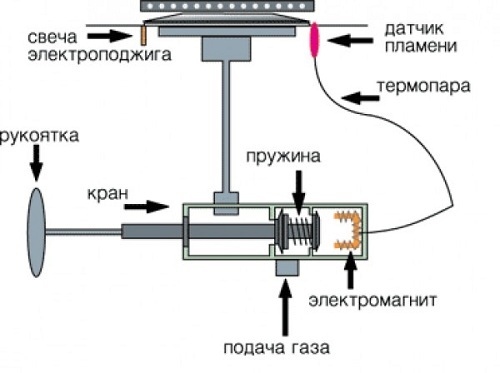

When setting up the cooker, it may be necessary to work with the gas control valve and its thermocouple. If the flame goes out regularly at the minimum level of fuel supply, it is possible that the problem lies in the gas control. The principle of operation of this option is based on a special sensor that reacts to the energy released during the combustion process. If the flame is suddenly extinguished, the thermocouple sensor cools down, which serves as a signal to stop the gas flow.

The simple operation of a small sensor can prevent dire consequences. Therefore, the working surface of the stove and its parts must be kept clean.

However, oxidative processes and a decrease in sensor sensitivity due to the ingress of liquids or the formation of plaque from food deposits can provoke an incorrect gas shut-off outside the emergency situations. Therefore, both the stove and this block should be kept clean, if necessary, call a master for cleaning.

If you are faced with an unusually noisy burner operation, we recommend that you find out the cause of the cooking zone noise and ways of elimination.

Conclusions and useful video on the topic

The function of a burner without a diffuser and the potential flame size when cooking directly from the burner is shown in the following video:

An example of the operation of jets for bottled gas in a hob connected to the main gas pipeline is clearly shown in the following video. After replacing the nozzles, the flame becomes almost perfect:

Interfering with the design of a gas burner is an unacceptable and risky idea. Residents of apartment buildings should be especially responsible, because in the event of an accident, not only their own lives, but also the fate of all neighbors are at stake. Take the choice of equipment seriously, calculating in advance the power of the equipment necessary for comfort, so that after the purchase there is no need for a dangerous and unjustified modification.

Would you like to share your experience of increasing the power of a hotplate? Tell us about it in the comments block, join the discussion - we and our readers are interested in your opinion.

If you still have questions, do not hesitate to ask our experts and other site visitors - the feedback block is located below the article.