You can build various useful devices from an old cylinder, from a barbecue to a homemade stove. But first you need to disassemble it, and this will require skill. The first step is to deal with the valve.

Not sure how to unscrew a gas cylinder, but are determined to do it yourself? We will help you deal with this issue. This article describes the main stages of unscrewing the valve and provides useful recommendations that will help you cope with the solution of this task. Also selected step-by-step photos and thematic videos.

The content of the article:

- Types and device of the valve

- Detailed instructions for unscrewing the tap

-

An overview of the best ways to unscrew the valve

- Method # 1 - clamping the shoe in a vice

- Method # 2 - clamping the crane in a vice

- Method # 3 - vise + metal corner

- Method # 4 - using two keys

- Method # 5 - welding the shoe

- Method # 6 - belts + key

- Method # 7 - fixing the balloon in the pit

- Safety rules when working with the valve

- Conclusions and useful video on the topic

Types and device of the valve

Before moving on to practice, you have to get a little familiar with the theory and figure out in which direction the valve on a household gas cylinder should be unscrewed. And also briefly consider the device of the cylinder and the valve itself. This knowledge will help you to quickly cope with the task.

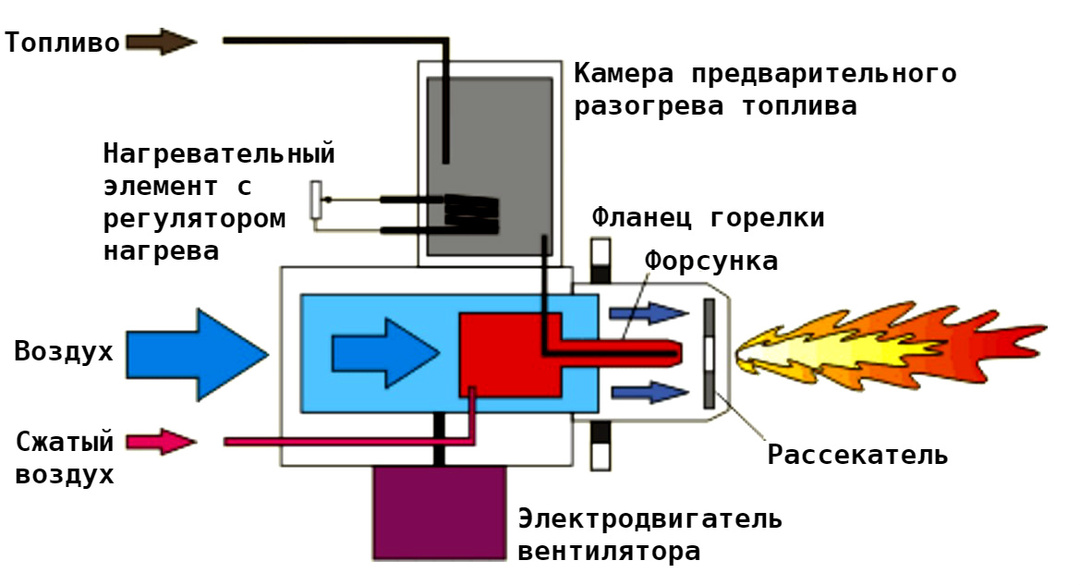

So, the main structural elements can be viewed in detail in the following image.

The design of the cylinder and valve is extremely simple. Depending on the chosen method of unscrewing the crane, it is necessary to use a shoe, cylinder lining rings to ensure reliable fixation of its body

Gas cylinder valve Is a shut-off valve used for storage, use, filling and safe transportation of pressure vessels (cylinders). The peculiarities of their use are regulated by Resolution No. 91 on safe operation of June 11, 2003, which states that each product must comply with GOST, be marked with the designation of the working pressure and temperature.

Most often, on propane-butane cylinders, you can find VB-2 and VB-1 valves. The body of such a crane is extremely simple and is equipped with a handwheel that can be easily rotated by hand. Such valves are installed on gas cylinders for pressures up to 1.6 MPa. It is possible to join them balloon reducer and a pressure regulator, for which there is a union nut with a left-hand thread in the valve design.

Connecting dimensions of the VB-2 brand valve:

- at the outlet for gas sampling SP 21.8 - 14 lines per 1 "left;

- for installation on a cylinder - tapered thread with a diameter of W19.2, W27.8, W30.3.

The side fitting of the valve of a cylinder used for storing flammable gases is always made with a left-hand thread. But for non-flammable - on the right. This measure is designed to protect the ordinary user who decides to independently attach the cylinder to gas-using equipment.

This prevents accidental explosive mixing of, for example, propane-butane or hydrogen with oxygen.

As for the material of manufacture, the valves are made of steel or brass. The product body must contain information about the permissible pressure.

Detailed instructions for unscrewing the tap

Looking for information on how to quickly and safely unscrew the valve on a propane-butane gas cylinder? Then read our instructions and see the step-by-step photos posted just below.

To easily cope with the valve, which can "sit tightly" in the neck of the cylinder, you will need to apply force. And, depending on the tools at hand, an assistant may be needed.

If you have a single cylinder, and you are going to twist the valve for the first time, you will have to tinker until you get used to it. If you are going disassemble the balloon and put the manufacture of various homemade products from cylinders on stream, then you simply cannot do without good tools at hand.

First you need to release the remaining gas, if any, in this cylinder. For this, it is enough to turn the valve flywheel in the direction indicated on it. If there is still gas inside, you will hear a characteristic hiss - this is the remnants of liquefied gas coming out.

After unscrewing the flywheel of the valve, you need to turn the cylinder over and drain the remaining gas and condensate accumulated at the bottom of the vessel into a previously dug hole. It is advisable to protect hands and face with gloves and a mask, respectively.

So that the gas residues do not harm in any way, they must be disposed of immediately. The best option is to burn it out. It can burn for a long time. When the fire has died out, this place can be sprinkled with bleach or whitened, which will get rid of the unpleasant smell.

Then you need to fix the cylinder body. How to do this depends entirely on your imagination and the devices at hand. For these purposes, they use welding, metal pins, a vice, a board, clamp the balloon with a wheel of a large car, fasten it with a belt to a tree and many other options. Therefore, choose for yourself the method of fixing that will be convenient for you.

The main task is to immobilize the balloon. We will consider the process of untwisting a valve using the simplest example - using a vice. You can find step-by-step instructions in the next photo collection.

Image gallery

Photo from

The first step is to unscrew the valve and drain off the remaining gas. This should be done with extreme caution and preferably outdoors or in a well-ventilated garage.

To securely fix the cylinder body, a vice will have to be used. It is good if they are installed in a convenient place - this will make it easier to unscrew the valve.

Most often, home craftsmen take a gas wrench if the farm has a solid tool. If this is an inexpensive key of dubious quality, then it may not withstand the load and simply break. Therefore, it is better to pick up something stronger

It is necessary to clamp the bottom of the shoe (base-stand) of the cylinder with a vice. If there is no vice, then you can weld it to a metal surface in two places by 5-6 cm, and you can proceed to the next stage

Taking the key, it is placed on the square thread of the valve. The latter is screwed in with a sealant so that the connection comes out secure. And this, in turn, significantly complicates the process of removing the valve.

In order for the applied efforts to be enough to unscrew the valve, the home craftsmen prefer to lengthen the existing key using available materials - a metal pipe 1-2 meters long. There will be such a lever that will help move the valve off the dead center

You can now push firmly on the edge of the pipe in a counterclockwise direction. If it doesn't work, then you can press a little in the opposite direction, and then try to unscrew it again. When the valve has moved from a dead center, you can remove the lever and further unscrew it with a key

When the valve turns easily, you can put the key aside and continue to untwist it with your hands. This process will not take much time - another minute and the unscrewed valve is already in your hands

Step 1 - draining gas residues

Step 2 - preparing the vise

Step 3 - preparing a suitable key

Step 4 - clamping the shoe in a vise

Step 5 - securing the key

Step 6 - using the lever

Step 7 - screwing the valve with a wrench

Step 8 - manually retrieving the tap

In most cases, there are no problems with unscrewing the valve - such a simple method allows you to easily unscrew it.

An overview of the best ways to unscrew the valve

But the considered method is not the only one. Many DIYers offer a number of other options, using various tools at hand. We offer 7 simple ways to unscrew the valve using improvised means. If you don't succeed the first time, then you can always use another option.

Method # 1 - clamping the shoe in a vice

In a vice, you need to clamp the cylinder body. For which the shoe is securely fixed with a vice.

You will also need an adjustable wrench and a pipe to extend the handle.

After securing the cylinder shoe, a key is put on the valve. In order to have enough physical strength to untwist the valve, a metal pipe is put on the key handles

Putting on the mittens, it remains to grasp the elongated handle of the key and, applying force, twist it counterclockwise. It will be tight at first, but after half a turn, the valve will go much easier. At the end, you can unscrew it by hand.

Method # 2 - clamping the crane in a vice

The second method is no less simple than the previous one. All that is needed is to clamp the cylinder valve in a vice, and twist it by the body, using belts for this.

If there are no belts, but there are chains, then they can also be used. For which they need to be fixed on the cylinder body, with a valve fixed in a vice, and with the help of a crowbar or a long metal pipe, twist counterclockwise

The first turn will be difficult, and then you can complete the twisting by hand, setting aside the metal pipe.

Method # 3 - vise + metal corner

This option provides for the same type of cylinder fastening in a vice as the previous one - with a crane in a vice. But instead of belts and chains, you need a metal corner. It is welded to the shoe in two places.

A corner with a length of about 1 m must be welded with an offset to the right - you have to untwist the cylinder counterclockwise, so it should be convenient for the user to do this

This welding method is simple if you have a welding machine in your garage and know how to use welding. As for safety, you do not need to be afraid to weld a metal structure to the shoe - this way you will not damage the cylinder in any way.

Method # 4 - using two keys

To implement this method of unscrewing the valve, you will need two keys - No. 5 and No. 3.

With a large wrench (# 5), you have to tighten the thread, onto which the transport cap is usually screwed to protect the valve.

And wrench # 3 will be used to unscrew the tap. It is advisable to lengthen its handle using a suitable length of pipe.

If you do not have experience in unscrewing a crane in this way, then it is advisable to invite an assistant to implement this method. As long as one user holds key # 5, the second person will be able to turn the tap counterclockwise using key # 3 with a lever

Method # 5 - welding the shoe

If you have a welding machine and know how to handle it, it will be convenient to weld the base of the cylinder (shoe) to any surface. For example, to the metal legs of the table or to the workbench. Moreover, it is enough to fix the stand by welding in two places.

Then you can use the same # 3 wrench with a lever (the long metal tube that is put on the handles of this wrench).

You can also weld a corner to the shoe and fix it with improvised means. Or invite an assistant - he will hold the corner so that the balloon does not move while unscrewing the valve

Method # 6 - belts + key

Belts or chains have to pull the cylinder body to something firmly fixed - a corner, a tree trunk. Then take wrench # 3 and unscrew the tap, remembering that it has a tapered right-hand thread - i.e. you need to twist it counterclockwise.

As a solid support, you can use a tree growing on the site, or any other device suitable for this purpose. If the thread does not lend itself, you can take a key number 5

Method # 7 - fixing the balloon in the pit

Another reliable fixation method is in the pit. To begin with, you need to screw a metal tube up to 1 m long to the shoe. For this, you can use the existing holes in the shoe. If not, then drill.

Then, dig a hole about half the height of the vessel, place the prepared cylinder with a screwed tube inside, cover it with earth and tamp it lightly.

It remains only to take the key and turn the valve counterclockwise.

The method of burying the balloon is simple, but it will require a significant investment of time and effort from the performer - after all, a rather big hole has to be dug. But you can do without an assistant

In winter, instead of a hole, you can use an ice-hole by freezing a balloon in it.

Having figured out how to unwind a gas cylinder at home, you can safely apply any of the methods you like. But at the same time it is important not to forget about safety - working with a cylinder can turn into very disastrous consequences. Read on for more details.

Safety rules when working with the valve

If you have never been involved in unscrewing a crane, then it will not be superfluous to familiarize yourself with the safety rules before starting such work.

The operation of the valve is regulated by such documents as PB 12-368-00 "Safety rules in the gas industry", Resolution No. 91 of June 11, 2003 "Rules for the Design and Safe Operation of Pressure Vessels" and GOST 12.2.008-75.

Disassembly, repair and replacement of the valve should be carried out only by persons authorized to repair gas equipment. And the repair of a device under pressure is strictly prohibited. Therefore, if you notice that the valve is poisonous or faulty, then the right decision would be to contact a gas service representative, and not to repair at your own peril and risk.

If you want to disassemble an old cylinder in order to make a useful homemade product of the type potbelly stoves, smokehouse or gas grill, then it is worth remembering that these actions cannot be called safe. And you will have to be responsible for the consequences.

Home craftsmen are rich in ideas for constructing interesting and functional homemade products from old gas cylinders. So, a home barbecue will become not only a useful device, but also a very stylish addition to the interior of the gazebo.

All actions to unwind the cylinder should be carried out outdoors or in a well-ventilated garage or other room. But in an apartment it is absolutely impossible to do this - such an experience may end explosion.

Next, we will consider the basic safety rules that are important to follow:

- To drain off the remaining gas, slowly and smoothly unscrew the handwheel of the valve.

- Never disassemble or cut a pressurized cylinder.

- There should be no other cylinders near the vessel to be disassembled.

If you are just about to unscrew the valve and have not managed to do anything yet, and in the garage, where the cylinder was, you can clearly hear the smell of gas, you should ensure maximum ventilation of this room. Why open gates, windows, doors (if any), and leave immediately.

Conclusions and useful video on the topic

If you have never been involved in unscrewing the valve from the neck of the cylinder, we recommend watching the following video:

Unscrewing the valve using a vise, metal pipe and clamp:

Having familiarized yourself with the simple methods for unscrewing the valve of a gas cylinder, you can choose the most suitable one for yourself. But it is important to remember the safety rules - unfortunately, it is not uncommon for gas cylinders to explode due to the careless handling of ordinary people. Therefore, having weighed all the pros and cons, it is better to contact a gas station, where for a nominal fee they will unscrew the tap from the old cylinder or replace it.

Do you have your own opinion about how to unwind a gas cylinder in artisanal conditions using improvised means and would you like to share it with other users? Or would you like to share your experience with unscrewing a valve? Write your comments, add original photos, participate in the discussion - the feedback form is located below.