To replace an old steel water pipe with a new one made of polypropylene, three things will be required - polypropylene pipes, soldering iron with cutter and PPR fittings. You can master the assembly technology in 10-15 minutes, and the choice of pipe is usually limited to the selection of characteristics for the cross section and water temperature.

With PPR fittings, the situation is somewhat more complicated - there are many models, so it is easy to get confused and buy unnecessary additional material. What should you pay attention to?

The content of the article:

- Where are they used

-

Types of PPR fittings

- Couplings and tees

- Cranes

- Auxiliary products

- What are the technical characteristics of

-

Advantages and disadvantages

- Positive aspects of using polypropylene parts

- Negative aspects of the use of PPR fittings

- How polypropylene fittings are mounted

Where are they used

The simplest solution is to use a ready-made catalog of PPR fittings from a well-known company that produces polypropylene pipes and additional elements for them when choosing. In such documents there is everything you need for the correct selection of fittings.

You can also look into GOST R52134-2003, but the standard is written mainly for specialists and manufacturing companies of PPR polymer products, so the average user will not be interested. Although it has some interesting information about the durability of polymer parts made of PPR plastic.

Fittings are used for the following purposes:

- using couplings and adapters, polypropylene pipes are connected into one sealed structure, for example, a water supply system or a heating system circuit;

- the pipeline itself is connected to sources of hot and cold water, air, liquid media, as well as insertion into his body of various consumers, from household plumbing to radiators heating.

All existing models of PPR fittings are mounted on polypropylene pipes only by hot soldering, at least on one of the mounting holes. No adhesive or threaded methods are used to connect parts made of PPR polymer.

Hot welding provides a monolithic, seamless connection. This means that under radial or transverse loading, the junction of the PPR fitting with the pipe will not fail due to fatigue failure of the seam. As it happens on glued PVC, PD and compression couplings of metal-plastic pipes.

Therefore, polypropylene systems on welded fittings can be used for floor heating, any loaded surface. The scheme for laying and assembling pipes on PPR couplings is somewhat different from the generally accepted for plumbing or heating.

Types of PPR fittings

The simplest catalog of PPR fittings includes more than 40 models. Each type is made for 10 main diameters of a polypropylene pipe, from 20 mm to 63 mm.

The entire range of polypropylene PPR fittings is divided into four groups:

- couplings, adapters for splicing PPR pipes;

- elements for branching heating lines and water pipes;

- cranes, locking devices;

- service items.

Some of the fittings are cast only from polypropylene, they are connected to PPR pipes by soldering. Most of the range contains composite parts, consisting of a polypropylene body and a metal threaded insert. It can be a soldered female thread, an external fitting, a steel nipple with a brass union nut or a valve stem.

Couplings and tees

Used for joining individual pipe blanks. PPR couplings are divided into transitional and basic. The first type of fitting is used to switch from a smaller diameter polypropylene line to a larger one, connecting to a steel pipe.

The main couplings are used for soldering two or more polypropylene pipe blanks into one structure. In addition to the usual barrel or corner, tees and crosses are used for joining PPR pipes, both in a purely polypropylene case and with a metal insert.

It is necessary to additionally mention PPR corners or half-bends. Craftsmen always purchase several types of angular turns with different angles for assembly. Usually this is a right angle, 30O and 45O. From such a set of fittings, a bypass or transition of any configuration can be soldered.

Cranes

Two types of locking devices are used in the polypropylene communications system. These are full bore ball models and valve type valves. The latter are characterized by increased hydraulic losses, but are more reliable when working with high water pressure.

Also, angle ball valves are placed on heating radiators and on flexible pipes for connecting plumbing and boilers.

Regardless of the faucet model, coarse filters are installed in heating and water supply systems. PPR fittings with ball or disc locking element are highly sensitive to contaminants in the water.

Auxiliary products

Connection of consumers to the polypropylene pipeline is carried out using corner or double water sockets. For kitchens, showers and bathrooms, ready-made kits are used for installing faucets without using flexible hoses.

Also, the service group includes bypass PPR couplings, curved pipes, bypasses, transitional bridges, with the help of which they bypass obstacles at the pipeline installation site.

This also includes clips and mounting clamps, as an indispensable element of any polypropylene pipelines, although they are not full-fledged fittings.

What are the technical characteristics of

Polypropylene mass of the PPR brand, from which pipes are squeezed out and additional elements are poured to them, is a random copolymer of polypropylene. The material is not afraid of cold and hot water, weak acids and alkalis.

Most fittings, except for simple and transitional couplings, have a more complex device in comparison with pipes. Therefore, more rigid polypropylene 80 is used for their production. After leaving the hot stamp, the product does not deform and does not "float", as when using a more plastic and fluid random copolymer.

| Name | Value |

| Density | 0.9 g/cm3 |

| Melting temperature | 149 ℃ |

| Yield strength | 24-25 n/mm2 |

| Tensile Strength | 34-35 N/mm2 |

| Relative elongation at the moment of reaching the yield point | 50% |

| Linear expansion coefficient | 0.15mm/m℃ |

| Thermal conductivity at 20OWITH | 0.24 W/m℃ |

The fitting material starts to melt at 250℃. With prolonged heating up to 150 OWith PPR, the coupling loses strength and begins to float under pressure, so it is better not to use polypropylene parts for steam heating. In this case, the pipe itself, if it is reinforced with fiberglass or aluminum foil, can remain intact.

The maximum operating temperature is considered to be +95 ℃, in such conditions the PPR coupling is able to work for at least 20 years. More complex products - corners, tees, polypropylene filters will last about half as long. Therefore, in heating systems, metal fittings on adapter sleeves are used. Polypropylene can be used for plumbing.

At room temperature, polypropylene fittings are able to withstand pressures up to 100 bar for a short time. But it is worth remembering that this is not metal, any increase in water pressure by more than 20% of the working one leads to barely noticeable residual deformations.

Polypropylene water pipes are not tested with pressure above 20 bar for more than 10 minutes at room temperature. If you go beyond these limits, it is likely that filters, taps or adapters with metal fittings will leak.

Heating or plumbing systems brazed with PPR fittings only can be experimented with at higher pressures and at higher temperatures. Therefore, the craftsmen often do not connect the heating boiler after soldering the pipes (pressure limits up to 3 bar), but pressurize the line at a pressure of up to 30 bar for half an hour. If there is no leakage of water on the couplings, then the polypropylene part of the heating system is guaranteed to last 25-30 years.

Have you had to mount polypropylene components yourself?

Yes, and not just for myself.

0%

I made my own plumbing.

0%

Didn't have to. I have other pipes.

100%

Voted: 1

Advantages and disadvantages

Polypropylene pipes with additional PPR elements have been used in practice for more than 20 years. The increased popularity of water pipes and heating systems made of polypropylene, their gradual replacement old steel communications only confirms the correctness of the choice made in favor of polypropylene.

Positive aspects of using polypropylene parts

The most important advantage of using PPR fittings is the simple assembly technology. Soldering with a hand soldering iron one connection point takes several minutes, while ensuring a reliable connection of parts. At the same time, the quality of the joint on the PPR coupling is high.

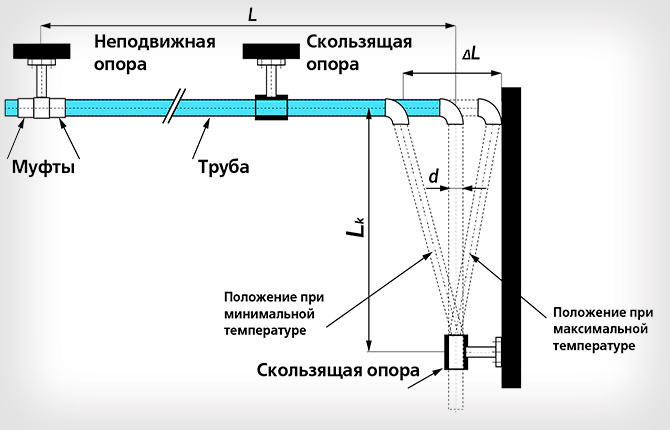

To assess the reliability, a compensation scheme for the movement of a pipe due to heating, which is welded into a heating line or hot water supply, can help.

Due to the high coefficient of thermal expansion, a long polypropylene pipe changes its longitudinal dimension. Every time a hot water tap is opened or a heated coolant is supplied to the heating system, the pipe lengthens by 4-10 mm, and contracts as it cools.

A variable load can unbend the PPR corner hundreds of times during the day. The advantage of polypropylene fittings is that at this point it is impossible to replace them with brass or steel ones - they are not able to withstand such a load.

In addition, the advantage of PPR fittings is the high sanitary safety of polypropylene. The material does not release any substances into the water, so it can be used for drinking without restrictions. While brass couplings and adapters are made from brass with a lead content of up to 2.5%. As the nickel plating wears away, the metal can dissolve in water.

Negative aspects of the use of PPR fittings

The main disadvantage of using couplings and taps made of polypropylene is the relatively weak resistance to polluted water. The more microparticles of sand and rust in the water, the faster the fittings wear out.

Service life for different models may vary. So, for example, couplings installed in compliance with soldering technology can last several decades. Whereas plastic-to-metal thread adapters, ball valves with a metal ball on hot water operate for no more than 15-17 years, after which they need to be changed. Fittings will last up to 30 years on clean cold water.

How polypropylene fittings are mounted

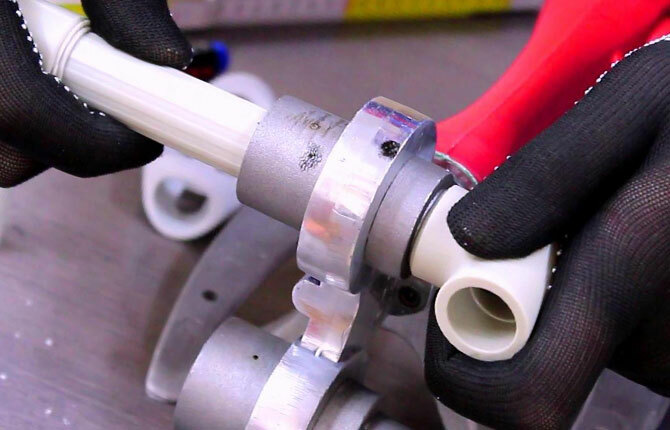

Thanks to the use of a special tool - an electric soldering iron and trimming scissors - it is possible to mount a PPR coupling or any other fitting in 5-7 minutes, depending on the diameter polypropylene pipe. The larger the transverse dimension, the longer it takes to heat the workpieces. The connection cools down to a safe state several times longer.

If the coupling or tap has a fitting or an internal thread for squeezing, then first of all you need to assemble, pack the FUM with tape and wrap the threaded connection. After the PPR fitting is soldered to the polypropylene pipe, it will be very inconvenient to install the squeegee.

The installation process of a polypropylene fitting is as follows:

- We select the appropriate model for the configuration. We remove the chamfer from the seat on the pipe, after which we check with a caliper the correspondence of the inner and outer diameters of the parts to be joined. Allow 0.1mm difference;

- install a set of nozzles on the soldering iron, set the heating temperature;

- determine the correct relative position of the fitting and pipe to be welded, it is advisable to immediately mark with a marker;

- We put the fitting and the PPR pipe on the nozzles with our hands, wait a few seconds, remove and firmly insert into each other.

We put off the soldered joint for 5 minutes, let it cool down so that the part can be held with the palm of the hand without much discomfort. We check the quality of the seam, along the connection line of the PPR pipe and the polypropylene fitting, melt or flash should come out. In addition, you need to check the part for clearance - make sure that there is no plug from the melt.

Polypropylene lessons in welding pipes and fittings with a soldering machine: video.

The advantages of PPR fittings are simple assembly of parts, reliability, high connection strength at relatively low cost of components. In practice, things are not always the same as in theory, many shortcomings appear after many years. Share with like-minded people your experience, problems and their solutions when using additional elements for polypropylene pipes in the comments. Bookmark the article.