A good option for a garden, cottage or private house is a polycarbonate gazebo. She looks attractive and respectable. The structure of the material gives the structure strength, reliability and durability. Relatively light material is easy to assemble with your own hands.

The content of the article:

- Advantages and disadvantages of polycarbonate gazebos

-

Ideas for giving and garden

- Square

- Round

-

Step-by-step instruction

- Cutting and fixing polycarbonate sheets

- Choice of design form

- Foundation, supports and floor

- Frame and upholstery

- Roof

- Operating rules

Advantages and disadvantages of polycarbonate gazebos

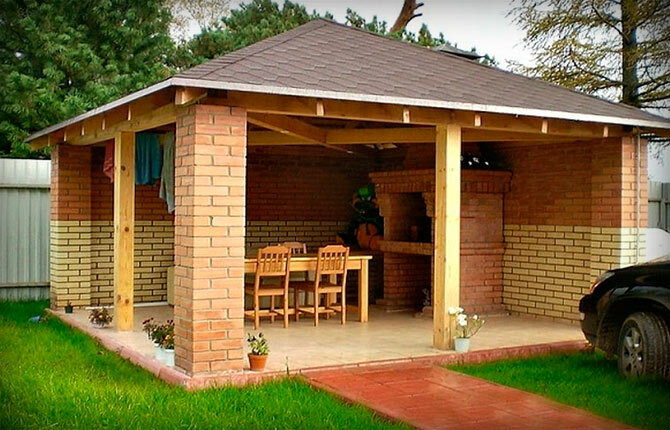

A light architectural structure, as a rule, is installed in gardens and parks, on the territory of a private residential building or in a country house. The gazebo allows you to feel comfortable outdoors. To some extent protects from bad weather: wind, rain, hot sunlight. In this regard, a polycarbonate gazebo is considered an excellent option for relaxation, meetings, dates and conversations.

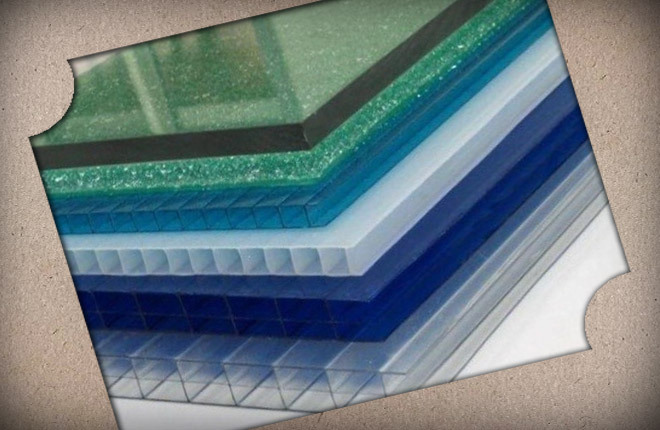

The main material is polycarbonate, polymer plastic. Until the moment of processing, the substance is stored in granules. Synthetic polymer is durable and frost-resistant, light and ductile, and is a dielectric. A variety of polycarbonate for construction - monolithic sheets and honeycomb panels.

A monolithic sheet is characterized by the same structure over the entire area. Its thickness is from 2 to 12 mm. Extra strong material has a thickness of up to 20 mm. When cut, it looks like ordinary glass. Cellular polycarbonate consists of two thin sheets interconnected by remote longitudinal partitions, 10 mm thick. They create a kind of honeycomb structure, are stiffeners. The air in the voids acts as a heat insulator.

Both types allow the formation of rounded surfaces, which cannot be done with glass. Nevertheless, to create interesting and unusual designs, the value of the bending radius should be taken into account. A similar characteristic is indicated in the technical documentation. Positive properties of polycarbonate:

- lightweight material;

- freely cut, drilled and takes the desired shape;

- does not lose its properties, does not deform;

- light transmission like glass;

- has high thermal insulation qualities;

- protects against UV radiation;

- 250 times stronger than glass;

- it is matte or transparent;

- has an extensive range of colors.

The material is moisture resistant. He is not afraid of insects, mold. In order to optimize the quality, additives are introduced into polycarbonate to better scatter light, flame retardant substances, and UV protection is applied. During manufacture, the value of thermal expansion is taken into account, the possibility of "internal rain" is excluded.

Monolithic and cellular polycarbonate.

Of course, polycarbonate has some disadvantages. In the summer, it will be hot in a closed gazebo. Therefore, it is necessary to provide for the possibility of ventilation or make the gazebo combined using wood and metal. The polycarbonate sheet does not absorb rain noise, unlike the honeycomb structure, which provides good sound insulation. But for the manufacture of the roof (to withstand showers, hail, snowfalls) you will need thick, and therefore expensive sheets.

Polycarbonate sheets are used in the construction of various structures. Suitable for covering large spans, large-scale glass structures. In case of damage to structures or collapse of ceilings, it does not threaten to cause serious injury. With success it is applied in agriculture and medicine, electrical engineering, production of advertizing production. Especially often greenhouses are closed to them.

Healthy: Arbors with their own hands made of wood.

Ideas for giving and garden

You can purchase a ready-made gazebo, assemble and install it on the site, or build it yourself. Closed-type gazebos are very popular, as they can be used at any time of the year. It can have hinged or sliding frames, combined with a summer kitchen. Such a structure requires pouring the foundation.

Open-type structures are a rotunda entwined with roses or grapes, a pavilion, a gazebo, an arbor. Ease of assembly, excellent material quality give vent to imagination. They allow you to build a gazebo of any size and shape: square, round, polygonal, arcuate, as well as complex asymmetric structures of several tiers.

According to the type of installation, gazebos are stationary and portable. The first are usually built on the foundation. The second, with a polycarbonate roof, can be installed on any type of soil, in any corner of the site. It is enough if it is a flat and dry area on a small hill so that rainwater does not accumulate on it.

According to the degree of equipment, the gazebo provides for a minimum of a canopy, a table and two benches, and may have original configuration, serve not only for eating, be a creative decor, decoration of the site, a place for children's games.

According to the type of construction, simple structures are distinguished - supports with a canopy. Complex ones have an original irregularly shaped base, a multi-level roof.

Arbors are small in size, up to 10 m2. They are designed for 4-6 people. Their construction and maintenance is inexpensive. Medium (10–20 m2) will accommodate 10-15 people. Large, over 20 m2 - in fact, this is a canopy, an open structure. Rectangular or hexagonal in shape. Used for canteens, not in the areas of boarding houses, holiday homes, beaches.

To build a gazebo, you need a frame. Usually it is made of wood, brick, metal, profile pipe. Walls are sewn up with polycarbonate sheets, a roof is made. A roof made of colored plastic creates the feeling of a sunny day in the most cloudy weather.

Square

The most popular type of gazebo is square or rectangular. It's easier to build it yourself. Straight lines require a minimum of materials. A roof or canopy made of polycarbonate is installed on poles, frames. Stone or metal elements are used as decorations: carving, openwork forging.

Inside, the most ordinary standard furniture can be successfully located. Square or rectangular country arbors have dimensions: 2x2; 3x3 m or 2x3; 3x4 m. As for design, such a gazebo can be decorated in high-tech or loft style.

Healthy: We build a modern gazebo with a barbecue for a summer residence with our own hands.

Round

Pergolas of a similar shape are also popular, especially unusual options. The advantage of the arcuate is its streamlining. Domed can withstand strong winds. Original open structures in the form of a barrel or a hemisphere perform not only a practical function, they decorate the site.

A polygonal gazebo requires serious calculations, drawings and markings. They can be made without side walls and look great, but the construction time of such structures increases significantly. For this type of construction, Chinese or Japanese-style finishes are chosen.

Step-by-step instruction

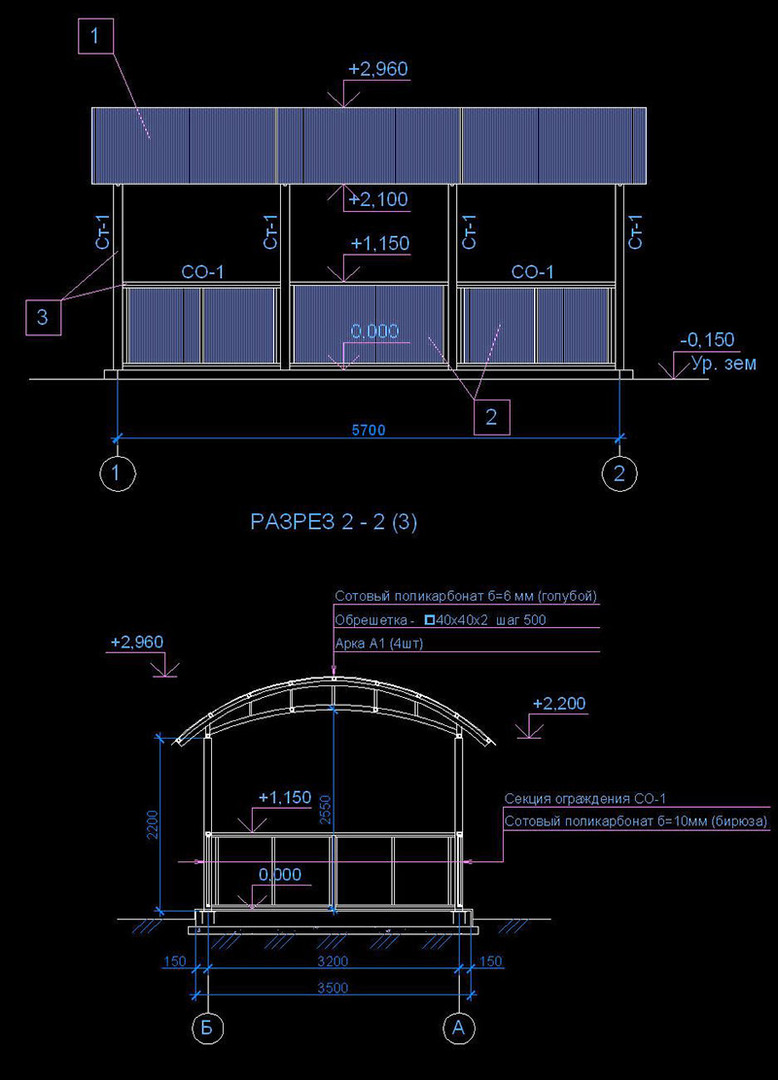

A summer gazebo is indispensable in a garden or summer cottage, it allows you to comfortably relax, unwind after hard work, get together with the whole family, celebrate a holiday. To build the simplest classic polycarbonate gazebo, you need to make a drawing or find it on the Internet.

The drawing gives an idea of the dimensions, how the building will fit into the site, and will allow you to calculate the amount of materials needed. After the components, accessories are purchased, the tools are prepared, you can install the building, according to the step-by-step instructions.

- Site preparation.

- Assembly and installation of the foundation, supports or frame.

- Cutting polycarbonate according to the given dimensions.

- Bending the canvas perpendicular to the partitions.

- Roof installation, location and fixing of parts.

- Parapet lining.

- Framing polycarbonate with a starting profile.

Next, finishing work is carried out. When using a metal frame and polycarbonate sheets, the manufacture of a gazebo is within the power of a person who does not have significant experience in design and construction.

Interesting: How to build a comfortable metal gazebo with your own hands.

Cutting and fixing polycarbonate sheets

Polycarbonate is easy to install. It is easy to install and remove if necessary. It should be remembered about its technological features. To avoid deformation, accuracy is required in the process of attaching sheets to the frame. For cutting, use a jigsaw, hacksaw, hand saw. You can use a circular disc for aluminum. There is practically no waste, spoiled pieces.

If the material has been stored in a damp room, it must be blown out with air before use. After cutting, close the ends with aluminum adhesive tape, sealant or trimming profile. You can not step on a polycarbonate sheet, installation is carried out only from the stairs.

Choice of design form

Garden and country gazebo can be made open or closed. Install in a permanent place or make collapsible. It all depends on its functionality, time of use (year-round or only in the "garden" period), the number of users. An important aspect is the availability for the acquisition of the necessary materials, financial ability, elementary skills in construction.

The most acceptable design option for a summer residence is a gazebo made of a profile plastic pipe and polycarbonate. To use the building all year round, it must be closed. Due to the plasticity of the material, it is possible to give it any shape, with different roof options. It should be remembered that a domed roof is the most resistant to loads in the form of snow and rain.

If you add forged elements, make metal barriers, such a structure takes the form of a rotunda. Inside you can put a small wooden table, benches.

Tools and materials

Cellular polycarbonate is lighter and cheaper. Monolithic is much more expensive and heavier. The thickness of the material matters. For the reliability of the sheathing, a sheet of 8 mm thick is required. To determine its quality, you need to check the specific gravity. The weight of such a monolithic sheet is at least 9.6 kg.

Cell sheet options are as follows:

- 2100 x 60 mm; 2100 x 120 mm;

- thickness - 4; 6; 8; 10; 16; 20 mm;

- transparent or bronze (color on request);

- guarantee - from 10 years.

Monolithic polycarbonate:

- 2050 x 3050 mm; 2050 x 6100 mm;

- thickness - 2; 4; 6; 8; 10 mm;

- transparent, color — under the order;

- warranty - 15 years.

Polycarbonate expands when heated, so thermal washers are used for fastening. The end sides of cellular polycarbonate should be isolated from the penetration of water, evaporation with special plugs. The protective film that covers both sides of the sheet should not be removed in advance.

Self-tapping screws must be with a hex head with an additional press washer and a rubber gasket. Fasteners should not be overtightened to prevent cracking of the material. You also need roofing screws or a detachable profile. For a metal frame, a welded joint or bolted connection is used.

During construction, you will still need nails, screws, nuts, bolts. To process wooden surfaces, you need sandpaper, glue, paint, varnish. Of the tools you will need a drill with drills, a screwdriver, screwdrivers, a hammer. Shovel for installing supports, sand, cement, expanded clay or stones.

Article for you: How to make a gazebo from a profile pipe with your own hands.

Foundation, supports and floor

A polycarbonate gazebo does not require a serious foundation. A monolithic foundation is necessary if it is a capital structure - brickwork with wooden elements, arranging a fireplace or barbecue. Such a structure weighs quite a lot. It will require a shallow strip foundation.

Construction begins with site preparation. If the floor in the gazebo is not provided, the site is leveled, holes are dug and support posts are installed in accordance with the shape of the gazebo and the drawing. Pieces of metal are welded onto metal supports, lowered into a pit and poured with concrete. Weld horizontal jumpers at a certain height to equip the railing. They will later be attached to the skin. To make the floor, the site is concreted or paving slabs are laid.

Frame and upholstery

More often than other materials for the frame, metal is used. A profile pipe of medium section will make the building stable and of high quality. A gazebo can be built using two different materials. For example, a timber frame is sewn up not only with clapboard, siding, but also with polycarbonate. The metal frame is more durable. The blanks are cut before installation, cleaned of rust, primed. Wooden is immediately made on the spot, treated with antiseptics and flame retardants.

Roof

The roof can be single, gable or domed. If it must follow the contours of the building (hemisphere), polycarbonate simply and effectively solves this problem. A metal crate of the desired shape is made. Installation starts from the center. Jumpers are installed between the stiffening ribs. Next, the roofing is done. Polycarbonate is screwed with self-tapping screws, in increments of 400–500 mm.

Reading: Do-it-yourself gazebo with a pitched roof.

Operating rules

For the winter, an open or semi-open gazebo should be covered with an awning, old frames, wrapped with a film or other dense material. There are some recommendations, subject to which a polycarbonate gazebo will last a long time.

- Rigid fastening to the ground should be provided to prevent demolition in strong winds, storms.

- If it is an open prefabricated structure, it should be dismantled and stored indoors for the winter.

- Protect the frame from mechanical damage.

- To ensure light transmission, the polycarbonate surface must be washed with a cotton cloth and detergent (without ammonia and solvents).

- Do not expose abrasive parts to chemicals.

To be sure that the material will last the period declared by the manufacturer, you need to buy it from reliable suppliers. This is a guarantee that polycarbonate will not lose its properties, and the gazebo will protect from heat and cold for a long time.

If there is a gazebo on the site that you built yourself, tell us about the intricacies of its manufacture. Leave a comment, share the article on social networks, bookmark it.