When making products from concrete, gypsum and other building mixtures, a vibrating table is used. You can collect it for domestic needs yourself. Before making a vibrating table, a detailed drawing is created and the necessary tools and materials are prepared.

The content of the article:

- Principal design

- Required materials and tools

-

Manufacturing of structural elements

- bed

- Elastic elements

- Eccentric

- Production and installation of a vibrating platform

- Motor selection

- The simplest design

- Finally

Principal design

The vibrating table is a surface designed for tamping building mixtures.

Industrial and domestic vibrating tables have the same principle of operation. With their help, paving slabs, cinder block, gypsum block, etc. are made. In the process of vibration, the building mixture is compacted and follows the contours of the form. At the same time, air bubbles come out of the solution, which makes the product durable.

The vibrating table consists of several elements:

- Bed. Heavy metal structure with brackets for fixing the vibrating table to the floor. The bed is a fixed part of the equipment.

- Tabletop. Metal sheet surface. Along its edges there are bumpers that prevent the forms from slipping during the operation of the vibrating table.

- Elastic pillows. Use springs or rubber parts.

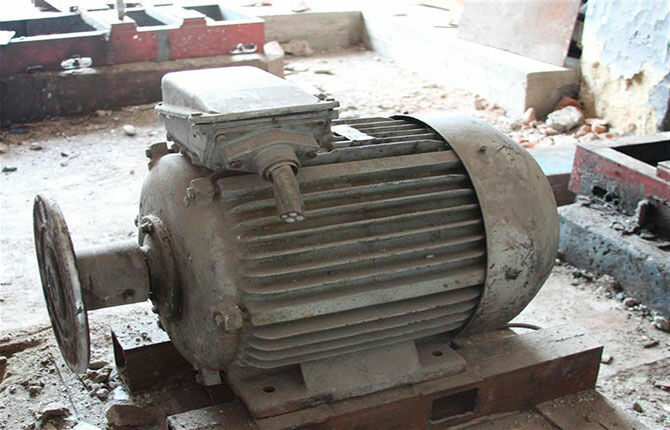

- Engine. To make a vibrating table on your own, they select an asynchronous motor powered by a 220 volt variable network.

- Eccentric. The shape and weight of the element with a displaced center of gravity are selected separately for each vibrating table.

- Control block. To turn on the electric motor, a starting device and a switch are installed on the vibrating table.

The frame is fixed to the floor. In the upper part, the working surface is fixed to it through the spring elements. An electric motor with an eccentric on the shaft is attached to the table top. When turned on, the eccentric creates vibrations and transmits them to the surface. The frequency and strength of oscillations depends on the speed of the electric motor and the weight of the eccentric.

You can make a vibrating table at home on your own. This requires minimal technical knowledge and welding experience. Following the sequence of actions, it will be possible to make a vibrating table.

We bring to your attention an article about how to do anddo-it-yourself inversion table.

Required materials and tools

Before you make a vibrating table for tiles, cinder blocks and other products, prepare the material and tools. The list may differ and is selected separately in each case. For work you will need:

- A metal sheet. The minimum thickness depends on the frame type. The thinner the sheet, the more massive the crate needs to be made.

- Corner for sides.

- Profile pipe, channel, bar, etc. for the manufacture of the frame.

- moving elements. They use metal springs, pieces of rubber or pillows designed to mount a car engine.

- Electric motor. Power is selected based on the size of the vibrating table. For domestic needs, an electric motor with a power of up to 1 kW is sufficient.

- Welding machine. Surfaces are connected by welding of any type.

- Electric drill and a set of drills for metal.

- Angle grinder with cutting discs.

- Electric motor of the required power.

- Control block.

- Fasteners.

- Plastic clamps.

- Eccentric.

Eccentric

Manufacturing of structural elements

Before you make a vibrating table yourself, you should draw up a detailed drawing. So it will be possible to calculate the amount of material and take into account the nuances of the design at the development stage.

You can use ready-made drawings of the vibrating table. During operation, strictly observe the specified dimensions.

bed

To make the base, 4, 6 or 8 metal pipes are vertically installed. Between themselves they are welded with transverse stripes or corners. For work, a flat area is selected. The top and bottom edges of the pipes must be in the same horizontal plane. To do this, use the water building level.

In the lower part, pieces of sheet metal are attached to the legs. Holes are made in them for fastening to the floor covering. On the other hand, glasses from pipe scraps or brackets for attaching elastic pillows are installed on the legs.

A box is mounted on one of the sides, designed to mount the control unit. The height of the location is selected so that the operator does not lean towards the buttons during operation.

The vibrating table is attached to the floor covering. To avoid displacement of equipment when ramming building mixtures, the legs are securely fixed to the floor with anchors. Under the action of vibration, threaded connections are spontaneously unscrewed. To eliminate this, a lock washer is installed under the anchor nut.

Elastic elements

In the upper part of the frame, spring parts are installed. The method of fastening is selected based on the type of element. Metal springs are mounted in glasses. automobile pillows are screwed with a threaded connection. At this stage, several rules are followed:

- The length of the springs must be the same. Skewed top surface will cause molds to slip during operation. It will be impossible to use the vibrating table.

- When fixing the elastic elements, lock nuts are installed.

- The height of the springs must be sufficient so that the top surface and the frame do not come into contact with each other under the influence of the weight of building mixtures on the vibrating table.

Eccentric

Oscillatory movements are transmitted to the vibrating table from a motor with an eccentric on the rotor shaft. It is a part with a displaced center of gravity. When the armature of the electric motor rotates, vibrations are formed under the action of centrifugal force. The force of vibrations transmitted to the vibrating table is changed by shifting the center of gravity. You can make the details yourself:

- Cut out 2 ovals from sheet metal 8-10 mm thick.

- Connect the workpieces to each other. In this case, a clamp or vice is used.

- Drill holes for attachment to the rotor shaft. The holes are not located in the center of the parts, but with an offset.

- A compass draws a line at the same distance from the hole made.

- Drill several holes along the line. They are needed to make the fastening of the ovals a threaded connection.

After that, the parts are installed on the armature of the electric motor. During operation, the center of gravity of the eccentric is changed by shifting one shaft relative to the other.

Production and installation of a vibrating platform

The upper surface of the vibrating table must be made of a flat sheet. Structural rigidity is given by making a crate from a profile pipe, angle, channel, etc.

The rigidity of the tabletop is necessary to eliminate the high level of noise during use.

It is recommended to make a side around the perimeter of the tabletop. Its height is 30-60 mm and is selected separately. For the manufacture of the side use a corner. It is attached to the countertop by welding or threaded connections.

In the center of the crate of the table cover, a bracket is made for mounting the electric motor. At the same time, the quality of welds is monitored. The junctions of the unit with the crate are subject to high loads. Poor quality welds will lead to failure of the tamping equipment.

The vibration platform is mounted on movable cushions with the engine down. The springs are attached to the tabletop. When installing a vibrating platform, monitor the correct location of the surface in a horizontal plane.

After connecting the parts of the table, the power wires of the unit are attached. To avoid breakage during vibration, the wiring is fixed to the structure with clamps. In this case, between the upper and lower parts of the product, the wire is located with sagging. The presence of a loop compensates for the vibrations of the upper part. The trigger and control buttons are placed in a box.

Motor selection

The power of the unit is selected based on the size of the table. For domestic use, single-phase asynchronous motors with an operating voltage of 220 V are suitable.

In some cases, to make a vibrating table, use electric motors from used household appliances.

To increase functionality, the engine control unit is equipped with a speed controller. So change the intensity of oscillations for different building mixtures.

When choosing an electric motor, attention is paid to the reliability of fixing the rotor bearings. During the operation of the table, the bearings are loaded. Seats wear out due to vibration.

The simplest design

Making a vibrating table is impractical if you need to make several cinder blocks or slabs. You can compact the building mixture in the form using a simple design. For this:

- Spring elements are attached to the surface. These are rubber pads, springs, car tires, etc.

- A shield made of wood or metal is laid on top.

- Forms with a building mixture are located.

- Create oscillatory movements of the shield. To do this, tap on the surface with a hammer. The intensity of oscillatory movements is increased by a drill in the puncher mode. The power tool chuck rests against a shield to transmit vibration.

So it is possible to make the contents of the form sufficiently dense without using a vibrating table with an electric motor.

Finally

You can make a vibrating table at home with your own hands. It is important to choose the right technical characteristics of the electric motor. You can change the intensity and force of oscillatory movements by shifting the center of gravity of the eccentric and adjusting the engine speed.

At the initial stage, a detailed drawing with a description of the dimensions is created. In the manufacture, individual protective equipment is used (glasses, welding shield, gloves, etc.). In this way, burns and injury can be avoided.

Do you use a vibrating table for compaction concrete? Do you use a ready-made design or did it yourself? How is your equipment set up? If the article was useful to you, make a repost on social networks and bookmark it.

The video shows the process of making a homemade vibrating table:

Do-it-yourself grounding device in a private house, the procedure for carrying out installation work. You can read about it on our website. link.