Almost every owner of a country house sooner or later faces the issue of laying paving slabs. Of course, you can use the services of professionals, but if you have the time and desire, you can do this work yourself.

In this material, we will tell you how to properly lay paving slabs so that it pleases the owner of the site for decades. In order to get a flat surface, it is enough just to follow certain rules, which we will discuss below.

The content of the article:

- Features of the choice of material

- Options for laying paving slabs

-

The procedure for laying tiles

- Stage number 1 - marking and excavation

- Stage number 2 - arrangement of the drainage layer

- Stage number 3 - the base for masonry

- Stage number 4 - tile processing

- Stage number 5 - laying tracks

- Conclusions and useful video on the topic

Features of the choice of material

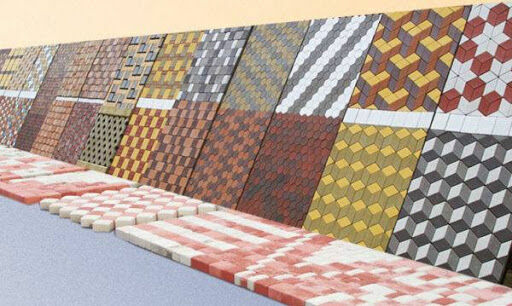

Paving slabs are one of the most popular materials for covering paths and entrances to buildings. This material is beautiful, aesthetic, easy to use, durable and, moreover, inexpensive.

Laying tiles is easy, this work may well be done by hand. But not everyone knows how to lay paving slabs, and this often causes numerous problems.

When choosing paving slabs, most buyers are primarily interested in value for money. Cheap tiles, as a rule, do not look very attractive and quickly fail, and you will have to pay more for high-quality material

But in order for the track to serve for many years, it is better not to be stingy and immediately purchase high-quality tiles than to regret your wrong choice for years.

It is important to determine what should be the thickness of the tiles that you are going to lay on the site. Pedestrian paths, as a rule, are covered with tiles 40 millimeters thick, and for laying car parking, tiles are needed much stronger - from 60 to 80 millimeters. The same tiles are laid on the road near the site. The thicker it is here, the longer it will last.

Options for laying paving slabs

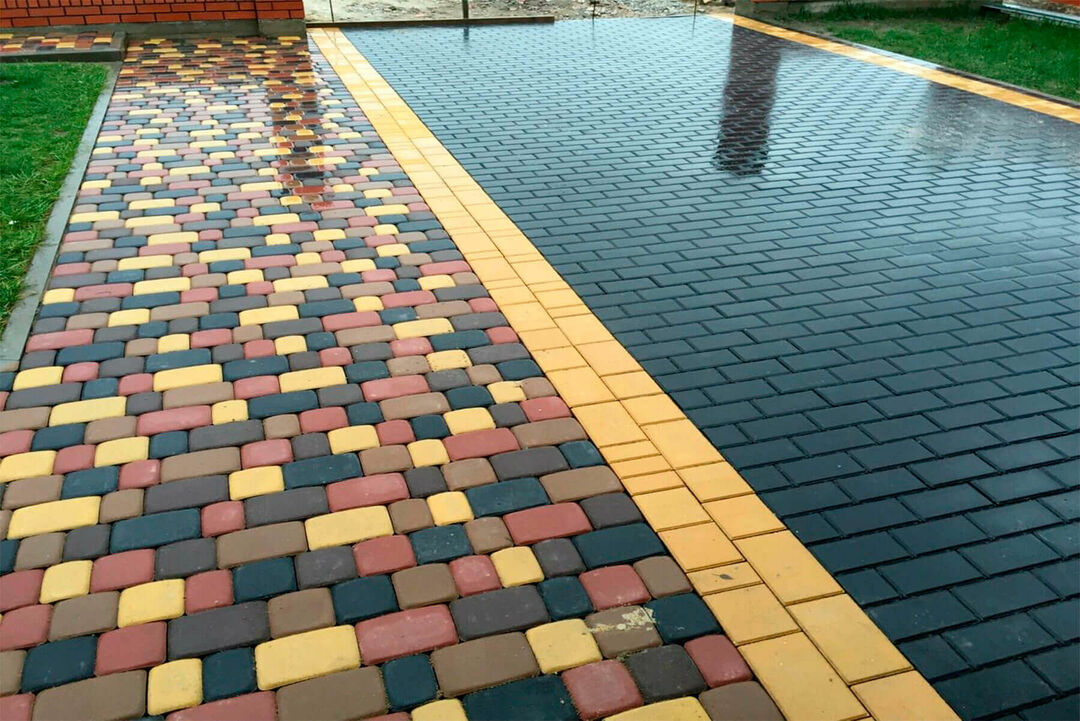

There are many different patterns for laying paving slabs. Even if the tile is plain, it can be placed parallel to the direction of the track, perpendicular to it, diagonally or in the form of some kind of complex pattern.

Let's look at the most popular ways of laying paving slabs:

- Linear. All elements are laid out parallel to each other, usually along the track.

- Brickwork. The laying direction remains the same as in the case of linear design, but each next row of tiles is shifted in relation to the previous one by half or by ¼ of the paving element.

- herringbone. The bars are laid at right angles to each other.

- block. The bars are stacked in blocks, two by two. Inside each block, the bars are parallel to each other, and the blocks themselves are turned perpendicular to each other.

Multi-colored tiles can be laid according to the scheme Chess board. The bars are arranged in blocks, in pairs, dark blocks are surrounded by light ones.

A large number of options for laying paving slabs, there are many. This allows you to choose the option that is ideal for the exterior of the site.

On large flat areas, you can lay the bars in a circle, in a radius pattern, or in an even more complex pattern, which is better to draw in advance.

The procedure for laying tiles

For self-laying paving slabs, in addition to the tile itself, some more materials are needed. First of all it is:

- stone or plastic border;

- cement grade PC 400;

- crushed stone, fractions no more than 40 mm;

- high quality sand;

- geotextile.

Also for work you will need: building level, rubber hammer, Bulgarian, concrete mixer, if you plan to lay tiles on a concrete base.

To determine where on the site it is worth laying tracks, you should use a plan that would detail the location of all buildings and other objects. On this plan, it will be necessary to build a track plan.

The width of the track must be sufficient so that two people can freely disperse on it.

The size of the area to be paved, the design of the base, the nature of the soil on the site and the conditions for using the tiles determine the amount of materials for work.

If it is planned to travel by car along the road, it is necessary to provide for the possibility of finding on it is a person who will not have to leave the path onto the lawn in order to give way to a passing car.

Also, when building a plan, be sure to pay attention to the direction of the slopes along which water will flow from the tracks.

Stage number 1 - marking and excavation

After drawing up a plan, you can start marking the site. To do this, you need a tape measure and a cord. A row of pegs is driven in along the proposed path, onto which the cord is pulled.

The pegs should be 10 centimeters from the edge of the future track - borders will be installed on this narrow strip

After marking the site, excavation work begins. Its complexity is determined by the density of the soil in your area. If the soil is dense clay and in the future it is planned to bring bulk soil to the site, it is enough to simply level the surface of the clay.

If the soil is more complex, 30-35 cm should be removed from its surface throughout the area allocated for laying.

After digging a trench, pour a thin layer of sand on its bottom, level it and compact it properly. After that, you need to cover this layer geotextile. These precautions will protect the site from the germination of weeds and avoid the possibility of groundwater infiltration.

Geotextile should be packed tightly. Neighboring strips should overlap each other by 15-20 centimeters. Along the edge of the trench, the canvas should be tucked up at least 20 centimeters.

Stage number 2 - arrangement of the drainage layer

To organize drainage for collecting and draining water, it is necessary to pour a layer of crushed stone of a fraction of no more than 40 millimeters onto the bottom of the trench. The thickness of the layer should be 15-18 centimeters. This will avoid swelling of the surface of the tracks in the future.

Tamp the rubble properly and pour another thin layer of sand on top of it. It is necessary to lay a second layer of geotextile on the sand, which would allow moisture to pass down, but not allow it to return back

After completing work on the drainage layer, it is customary to take up the installation of curbs. They are made from a variety of materials - stone, concrete, brick, plastic, wood, etc.

The most popular traditional type of border is concrete, but recently borders made of durable and inexpensive plastic have begun to become widespread.

A curb made of concrete and stone is fixed with a mortar, and a plastic one with the help of special wedges sold with it.

Stage number 3 - the base for masonry

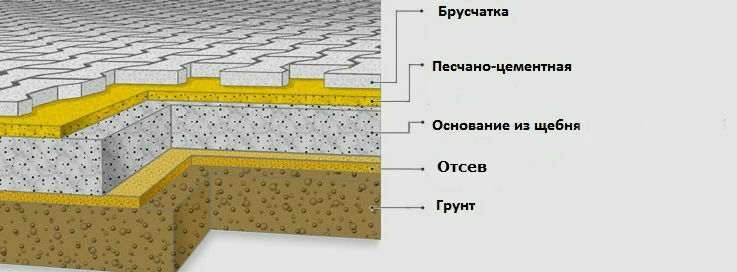

There are three types of support base used for laying paving slabs on footpaths: concrete base; cement-sand base; base of compacted sand.

A concrete base is more expensive than others, so it is used only if there are high loads on the tiles laid on the site. If the load is small and the soil itself is strong, you can make a simple sand base. But the most popular solution is a cement-sand base, suitable in almost any case.

Concrete base - expensive, but high quality

The laying of the concrete foundation should begin with reinforcement. Ready-made welded metal mesh with a cell size of 100x100 millimeters is perfect for this. You can also use old pipes, wire, rods, etc. From them it is necessary to lay out a lattice and tie the intersections with wire.

The resulting mesh should be installed above the drainage layer at a height of 3-5 centimeters, for this you can use stands made of stone or any metal. If the trench remains too deep for this stage of work, the excess space can be filled with compacted sand.

After that, the concrete mixture is prepared. Cement PC 400, sand and crushed stone are mixed in a ratio of 1:2:2. And it is better to order a concrete mix from the manufacturer, so that he delivers it to you directly to the site.

To create the most durable garden paths, it is recommended to use a concrete base. Concrete is poured at a time, its thickness should be 10-12 centimeters. As a result of pouring, the concrete surface should be below the ground by the thickness of the tile minus 3 centimeters

3-5 days after pouring the trench with concrete, it will be possible to start laying paving slabs.

Sand and cement - a base for every taste

If the tiles are laid on a mixture of cement and sand, they should be mixed in a ratio of 1:5. The thickness of the layer of dry sand-cement mixture is usually 12-15 centimeters. If the trench is too deep, you can do the same as in the case of a concrete base - pour river sand under the base and compact it well.

This is what the paving slab looks like. First, screenings are poured onto the soil, then there is a layer of rubble and only then a sand-cement mixture

During laying of paving slabs, the base must be dry. It should not be laid in rainy weather, as well as after or before precipitation. After backfilling, the mixture must be properly compacted so that it is even. This will greatly facilitate the upcoming tiling work.

Sandy base - if the soil is firm

The sand for the base should not contain lime and clay. River sand is preferred for use. The sand from the quarry must be washed. After backfilling, such a base must be well shed with water, compacted and leveled.

Stage number 4 - tile processing

Paving slabs are usually treated with a hydrophobic compound before starting the laying process. The tile treated in this way is not washed out by water, tolerates frost well and lasts longer than usual.

The treatment procedure also protects the tile from the destruction of its surface by fungus and mold.

Processing paving slabs with a water repellent will protect the path from destruction. The photo clearly shows the difference between the processed tile and the one that has not been processed.

Dip the tiles in a hydrophobic solution and dry it twice. By doing this work, you can go through all the tiled products you have and choose from them the most and the least quality, in order to then distribute them over the most and least noticeable areas of the laid out territory.

Stage number 5 - laying tracks

If the base of the tracks is made of concrete, it is customary to lay paving slabs on a layer of cement mortar. The solution should fill the joints as much as possible, the thickness of which should not exceed three millimeters. The laid out tile is leveled with a rubber mallet.

You should start laying tiles from the beginning of the path, settling on the already laid area, laying out new tile products in front of you and thus moving higher and higher along the path. After the laying is completed, all seams must be sealed with cement mortar.

Laying tiles on a cement-sand and simple sand base is carried out differently. The person laying the tiles is on a section of the path free from tiles, lays tiles in front of him and gradually steps back to the areas that have not yet been processed.

Every stone tapping rubber mallet. This is necessary to secure it on the track. If the surface of the track before laying the tiles is uneven, you can add or remove some sand or a cement-sand mixture. When the work is completed, the track is covered with a thin layer of the same mixture. Then this mixture is swept with a brush into the seams remaining after laying.

After all the tiles have been laid, it remains to water the path twice with water - immediately after the installation is completed and after two or three days.

Conclusions and useful video on the topic

Below is a video with a step-by-step guide to laying paving slabs:

Useful tips for laying paving slabs:

As you can see, there is nothing complicated in laying paving slabs. Even a novice home master can cope with this task, you just need to follow the instructions exactly. and strictly observe the technology of work, and then you will get a high-quality track that will last for many years.

Have questions about the topic of the article? You can ask them in the comments section, and our specialists will try to answer them as soon as possible. If you had to lay paving slabs yourself, please share your own experience with our readers. Tell us if there were any difficulties during the work and how you managed to cope with them.