Each, even the simplest gazebo, should look cozy, have a minimum set of necessary pieces of furniture. For a comfortable stay, there are ready-made garden kits. But, having basic knowledge, skills in carpentry, you can independently make benches and a table in the gazebo.

The content of the article:

-

Examples of tables in the gazebo

- from wood

- Hexagonal

- trimmed with mosaic

- With metal structure

- Dimensional drawing

- Building material and tool

-

Step by step construction process

- Board preparation

- Countertop manufacturing

- Making and attaching legs to the table top

- Strengthening the legs with a board

- Last finishing and polishing

Examples of tables in the gazebo

A gazebo requires a well-organized space. It should have furniture for family dinners, meetings with friends, a romantic dinner. When choosing the shape and design of furniture, you need to think through many nuances.

First of all, the set should be as compact as possible, functional and, of course, beautiful. Most often it is a table made of wood. Therefore, some points must be taken into account:

- gazebo area;

- type of building (open, closed, collapsible);

- how many people will need to accommodate at the same time;

- its shape and dimensions;

- the material from which the furniture will be made.

The table in the gazebo is the most exploited part of the furniture set, so it must be durable, comfortable, and even.

We must not forget about atmospheric phenomena: wind, rain, snow, scorching sun, temperature changes. It is necessary to provide convenient passages between the wall of the gazebo and the back of the benches. If you make a table in the gazebo with your own hands, you can save a lot.

Instead of bulky benches, the gazebo is often equipped with light folding chairs. When staying in the country is rare, folding furniture is the best option. It is easy to get it, spread it out, and in the absence of the owners, assemble and hide it.

How to build a gazebo:

- Arbors with their own hands made of wood

- How to build a comfortable metal gazebo with your own hands

- We build a gazebo from polycarbonate with our own hands

- How to make a gazebo from a profile pipe with your own hands

- We make a gazebo from improvised materials with our own hands

- We build a modern gazebo with a barbecue for a summer residence with our own hands

- How to make a beautiful gazebo from pallets

- Do-it-yourself gazebo with a pitched roof

- DIY hexagonal gazebo

from wood

It will perfectly fit into the space of the gazebo, a table and a bench made of wood will fulfill its intended purpose. When choosing a material, special attention should be paid to its quality. You should buy only well-dried boards. Lumber must be smooth, without damage, fungus and traces of insects. This will allow you to quickly, without problems, complete the assembly.

Conifers have a beautiful wooden structure. They are easy to process, but release resin, which can ruin the tablecloth or clothes. In this case, the pitching should be burned out, filled with putty from glue and small sawdust. After drying, treat the surface with fine emery cloth.

The best option is hardwood material: birch, ash, larch, as well as cherries, pears. The furniture is durable and strong, with a noble texture. But this type of wood is hard and difficult to process. Plus, it changes color over time.

It is not necessary to buy new wood. You can make a designer table from improvised materials, use old boards, bars, trimmings. Another option is to use pallets. They are pre-disassembled, planed and polished.

Any material requires treatment with an antiseptic, a protective compound, which will ensure the preservation of the wood texture and extend the service life. This is especially important if the table will always be in the open air. A similar procedure can be carried out before installation or after assembly. All cuts made during the fitting must be processed, the ends of the material must be protected from the penetration of moisture into the capillaries.

Round

Tables in appearance can be rectangular, square, hexagonal. According to the type of construction, there are stationary, folding or transformers. Their dimensions and shape depend on the area of the gazebo. So the round one looks original, visually expands the space, creates a relaxed atmosphere, helps to overcome the psychological barrier. The selected table design should not be dissonant with the shape of the gazebo and the overall style.

The tabletop can be placed on one massive rack with a cross at the bottom. The seats are also arranged in a circle. The table has the traditional four legs fixed at the corners. The most comfortable and stable design is one central support or three legs fastened with crossbars. There are folding round models. They are transformed into a flat product. They are convenient to transport, store, if necessary, rearrange to another place.

Healthy: DIY furniture from pallets

Hexagonal

Such a table will decorate the gazebo, will look good in a building with strict, pointed elements, will allow everyone present to feel independent and free. The support structure can be made in the same way as for a round table. Three beams in the form of an asterisk are fixed on the base cover with steel corners. In the center, a hexagon cut from the board is installed.

Next, fill the sectors between the bars. Planks begin to be laid in the center, moving towards the edges. To do this, the lining is pre-sawn into segments of the desired length, the ends are cut at an angle of 30 °. The prepared parts are nailed to the beam through a protruding chamfer.

Next, the countertop is treated with stain. Apply several layers of varnish, with intermediate polishing. The assembly of such a structure is quite laborious. But for a true master, this work will not be particularly difficult.

trimmed with mosaic

The table can be varied by cutting or slightly rounding the corners with an electric jigsaw. Scratches and crevices can be covered with wood putty. The tabletop is decorated with wood painting, burning, artificial aging, decoupage, tiled or mosaic. You can make a mosaic yourself by assembling a pattern from pieces of colored plexiglass. In the classic version, separate pieces are applied to the glue.

There are ready-made ornaments assembled on a self-adhesive basis. Waterproof chipboard is used as the base for the mosaic. For the convenience of drawing up a drawing, the plate is marked into sectors, observing symmetry. Separate fragments are laid out in a pattern, making the seams as narrow as possible. After the glue has dried, grout is applied, immediately removing excess with a damp cloth. The process is quite painstaking, but the table in the gazebo turns out to be original, beautiful and reliable.

With metal structure

The base for the table and benches in the gazebo can be made of metal. For this, a metal profile, corners, stainless steel, aluminum alloy, cast iron, aluminum pipes are suitable. The structure of the underframe can be welded. If for some reason welding cannot be used, then long and short bolts, hex nuts, brackets for fixing the tabletop will be needed for the connection.

Furniture for a summer residence can be forged. Its appearance will transform even the most unsightly area, suitable for gazebos of any type and style. Such designs look elegant, light, but in fact they are quite heavy. Such furniture is durable, reliable, and lasts for decades. With proper care, it is not afraid of corrosion, resistant to water and sun.

For you: DIY folding stool

Dimensional drawing

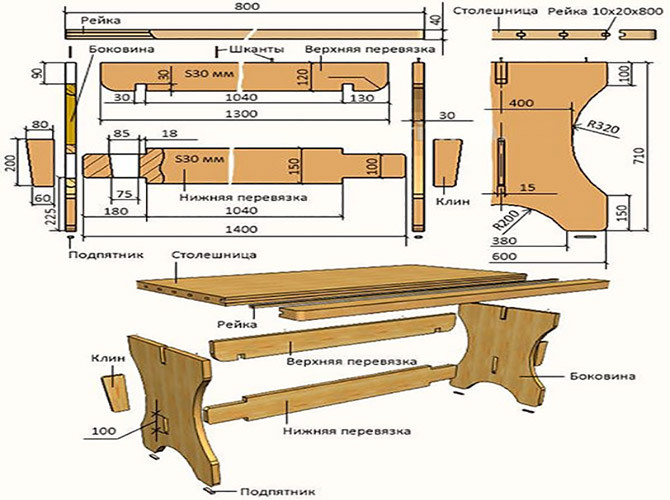

To make a table in the gazebo with your own hands, you need to decide what it will be like: general appearance, size, material. Not forgetting that, first of all, the structure must be strong and stable. First you need to calculate the exact parameters of the countertop, based on the area of \u200b\u200bthe gazebo. Then make an elementary sketch on a sheet of paper and apply all dimensions. Suitable drawings can be found on the Internet by substituting your dimensions.

Building material and tool

If the gazebo is wooden, the table is best also made of wood. However, there are no strict rules here. Combinations of wood with plastic, metal, bricks are possible. And yet the table top and legs are made of wood.

For their manufacture, a tongue-and-groove or unedged board (140x40 mm, length 1200 mm) is required. In specialized stores and carpentry workshops, ready-made shields can be purchased for countertops. Bars with a section of 60x40 mm, length 700 mm. Wood for legs and lintels, nails, self-tapping screws (length - 70 mm, Ø - 8–10 mm).

To build a table in the gazebo with your own hands, you need the following tools:

- hacksaw or jigsaw;

- drill or screwdriver;

- planer, chisel, hammer;

- milling and grinding machines;

- cutters, drills of different diameters;

- roulette, square;

- sandpaper, paint brushes.

- clamps, glue.

- protective gloves.

You will need tools for finishing: impregnation, antiseptic, stain, primer, varnish, paint.

Step by step construction process

Step by step instructions for making a table in the gazebo.

- Cutting planks to size.

- Bar preparation.

- Making the base for the countertop (framework).

- Leg manufacturing.

- Processing of all wooden parts (planing, grinding).

- Assembling the tabletop on the bars with self-tapping screws, dowels.

- Installing the tabletop on the frame.

- Leg mounting.

- Fixation of the entire structure.

- Re-treatment of wood.

Board preparation

For a table in the gazebo, dry wood is needed, otherwise, with temperature changes, the tree can “lead”. Once purchased, the boards are dried in the sun, then sanded as damp wood clogs the sanding wheel.

If necessary, they can be stretched. A particularly important point is the application of a composition with protective properties to the wood. Processing is carried out before and after installation. At the same stage, at least two cross slats or bars should be prepared for assembling the countertop.

Countertop manufacturing

Prepared boards are marked in size and cut into pieces. All parts must be straight, the same in width, then the countertop will be without gaps. They are laid out on a flat surface, face down.

Guide bars are laid on top, which will connect the individual parts to each other. Self-tapping screws and dowels are used as fasteners. They hold up well and don't ruin the look. This will make the cover strong and will not allow it to loosen.

In a closed gazebo, the top of the table can be made of laminated chipboard. This material is not afraid of water, temperature changes. Open sections are protected by a special PVC trimming. Plastic countertops are popular. But they are short-lived, afraid of direct sunlight, do not withstand heavy loads.

Making and attaching legs to the table top

Depending on the model, the table may have one central leg. Two, arranged in parallel, in the form of an inverted letter "T". Usually they are fastened together with a crossbar. The basis for small round tables is often three legs, the classic version is four legs.

The rectangular frame of the upper harness is made of thick and durable boards. They are joined end to end. The size of the box must be smaller than the lid. For the legs you will need bars of the same section, preferably square. The optimal table height is 80 cm. The legs are fixed at the corners of the frame using metal corners and self-tapping screws. Next, a countertop is installed on the frame, fastened with self-tapping screws.

The base can be made of brick, concrete, metal pipe. It all depends on what shape and how many legs you need. If necessary, they are fixed in the ground with cement mortar.

The solution solidifies over several days. But deepening or leveling the finished structure is possible only in the first two hours. Therefore, it is better to install it right away. Wooden bars buried in the ground or mortar can be protected from rotting with a special rubber-bitumen mastic.

Strengthening the legs with a board

It is possible to give the necessary rigidity to a wooden structure with a tsarg device. The tsarga is a board frame to which the legs of the table are attached in its upper part. It also has a table attached to it.

The drawer side performs not only a mechanical function, rigidly fastening all the parts into one whole. It is also a decorative effect that affects the aesthetics of furniture, its visual perception. An ordinary, unpretentious table is fastened with a straight board. In curved products of complex shapes, curved sides are used. Also, the tsarg boards can be decorated with carved ornaments.

In order for the table in the gazebo to be stable, additional fasteners are used. These are prolegs - horizontal parts (lintels) connecting the legs of furniture in its lower part.

Depending on the design of the table, they can be from a simple straight board, carved or round shapes. In common practice, the bridged pairs of legs are fastened to each other by a central tie piece. Such a structure turns out to be unusually strong and reliable.

Last finishing and polishing

After assembling and installing all additional fasteners, the corners are processed again and the table cover is ground. You can leave a beautiful pattern of planed wood. If you want to give a special color, it is covered with stain. A good finishing method is firing.

The effect is achieved using a building hair dryer, gas burner or blowtorch. The desired shade can be achieved by applying stain in two or three layers. Next comes the treatment with an antiseptic or a solution of hot drying oil. To save varnish, an antiseptic is used as a primer.

After the primer dries well, all wooden parts are varnished. Dry again, process with fine emery cloth, apply the next layer of varnish. The procedure is repeated several times until a smooth, almost mirror-like surface. It uses yacht varnish or any other for wood.

You can buy a ready-made table with benches. But, having elementary knowledge in carpentry and connecting fantasy and the Internet, you can independently make not only high-quality, but original, original furniture in the gazebo.

We also read: How to make a comfortable hanging chair

Share your own experience in making a table in the gazebo. Were there any difficulties in the process of work? Leave your comment, repost the article on social networks, bookmark it.