For most summer residents, the construction of a greenhouse "Breadbaskets" do-it-yourself - the best option for growing seedlings in small areas. The design has gained fame and popularity due to the principle of the reclining top of the greenhouse. Of all the options, the bread box can be considered one of the most convenient solutions.

The content of the article:

- Design Description

-

Construction process

- Preparation of tools and materials

- Calculation of dimensions and creation of a drawing

- Sash assembly

- Making the base of the greenhouse

- Assembling the swivel assembly and mounting the sashes

- Installation of the frame of the greenhouse "Khlebnitsy"

- We sheathe the frame with polycarbonate

- Results

Design Description

Greenhouse "Bread Box" from a profile pipe is also found under the names "shell", "clamshell". This is all the same version of a greenhouse or greenhouse, in its design reminiscent of a home box for storing bread.

Structurally, the greenhouse consists of three elements:

- The base is a fixed rectangular box on a frame made of a profile pipe, sheathed with a film or carbonate.

- The upper part of the arch type based on a ¼ arc, is installed on top of the base, covered with a film or polycarbonate. In some models of greenhouses, it is made stationary, but more often movable on hinges.

- The inner part of the "Khlebnitsa", or a sash, the size of a quarter of a circle, is hinged. The peculiarity of this design is that the sash can be rotated around a horizontal axis by 1/2 sector.

When opening the greenhouse, any outer or inner leaf of the Khlebnitsy greenhouse can be lifted by hand. That is, the lid can be opened from any side. This is convenient if you want to open the seedlings for airing and lighting, depending on the location of the luminary in the sky.

Construction process

The design can be welded or assembled from a profile pipe with bolts and corners. Facing of "Khlebnitsa" from polycarbonate. In the first case, the greenhouse-bread box turns out to be of a stationary type, in the second, the structure can be disassembled and folded in a barn in the country before the seedling growing season. It can be made from wood, but the quality is much lower.

Preparation of tools and materials

The process of step-by-step construction of a greenhouse consists of the following steps:

- blanks are cut from a profile pipe, then the outer and inner sashes are welded sequentially;

- in the same way, they cut out the profile pipe and weld the frame of the fixed base;

- install hinges;

- the frames of all three parts are covered with cellular polycarbonate.

For the manufacture of the "Khlebnitsy" greenhouse, a profile pipe 20x20 mm, 20x40 mm in the amount of 20 m each will be required. The frame is covered with cellular polycarbonate 6-8 mm thick. The dimensions of the greenhouse are chosen so that the carbonate can not be cut out in pieces, but sewn on with cut-off panels of 200 cm each.

You can cover the greenhouse with plastic wrap, but it is enough for a maximum of a season, besides, polycarbonate much better transmission rate of infrared and ultraviolet waves, most useful for seedlings and greenhouse greenery. Yes, and you have to put away from the trees.

Mounting polycarbonate on a frame made of corrugated pipes is a rather difficult task, you have to use special fasteners (self-tapping screws) with compensating washers. The situation is worse if it is necessary to join two polycarbonate sheets. In this case, it is necessary to use special strips laid on the joint between the panels. Therefore, most often greenhouses "Khlebnitsy" are built in small sizes, and besides, the larger the frame, the harder it is to manage the wings.

From the tools you will need:

- pipe bending machine;

- welding machine;

- Bulgarian;

- set of locksmith clamps;

- measuring tool;

- screwdriver with drills and a hexagon socket.

In addition, before final assembly, weld the hinges and paint the metal with enamel paint.

Calculation of dimensions and creation of a drawing

First of all, it is necessary to calculate the dimensions of the movable wings of the Khlebnitsy greenhouse. Since the inside completely goes under the top, they cannot be the same size.

All arcs used in the manufacture of sashes are cut from two identical blanks, bent in advance on a pipe bending machine. Therefore, the radius of curvature for them, regardless of size, is the same. Only the length of the sector around the circumference differs.

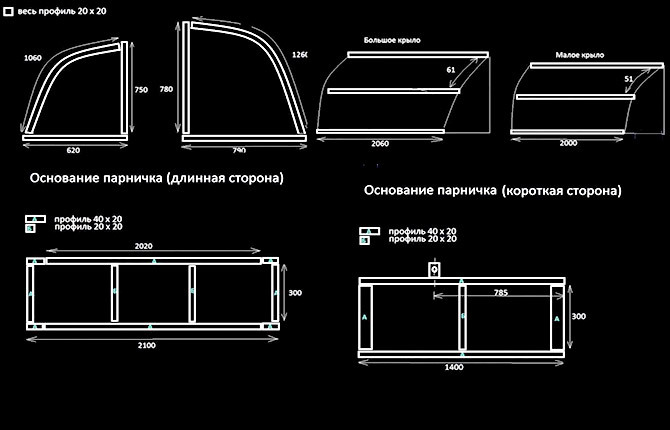

For the inner one, the length of the arc is 106 cm, for the outer one - 126 cm, respectively, the lateral legs for the first one are 75 cm and 62 cm, for the second one - 78 cm and 79 cm.

Assembly is carried out by installing three horizontal crossbars. At the inner sash, sections of the profile 15x15 mm are sewn with a step of 51 cm along the arc, at the outer one - with a step of 61 cm.

The lower base of the greenhouse "Khlebnitsy" for beds is made of a professional pipe 40x20 mm and 20x20 mm in the form of a conventional rectangular frame. Drawings, more precisely sketches with dimensions, are given below.

After assembly, you must not forget to weld a couple of plates under the hinge on the basis of the Khlebnitsy greenhouse. The plates are made of steel strip 5 mm thick.

Sash assembly

The first step is to assemble the sidewalls of the Khlebnitsy greenhouse. To do this, a set of two legs and an arc is laid out on a sheet of fire-resistant material. Before welding the parts, you need to make sure that they are in the same horizontal plane, otherwise the sidewall after welding may turn out to be a curve.

Next, you need to set the two sidewalls vertically, fix them at a distance of an equal crossbar and weld the bottom one first, then the top one. After adjusting the geometry of the sash, the middle horizontal crossbar is additionally welded.

After welding, the frames of the two wings are inserted into each other. Moreover, this must be done immediately, and not postponed to the final stage of assembling the Khlebnitsy greenhouse. This marking will help clarify the gap between the corner pieces. It must be within 10 mm.

If the distance is greater, then it is necessary to slightly bend the frame. In any case, both frames should not touch each other.

Another nuance - for the manufacture of the upper part of the greenhouse, a profile pipe with a small cross section and wall thickness is used. Therefore, it is necessary to cook with an electrode in points. Complete digestion of the seam line will need to be done after the final adjustment of the geometry of all parts of the greenhouse frame.

Advice! If possible, it is advisable to use a carbon dioxide semiautomatic device for welding.

Particular attention should be paid to welding the corner of the two legs. In this place, it is desirable to weld an additional reinforcing plate-kerchief or install in each corner an insert-strut 10-15 cm long.

Making the base of the greenhouse

The lower part of the greenhouse "Khlebnitsy" is a rectangular double frame 140x210 cm. The height of the vertical racks of the frame is 30 cm. To make the base of the Khlebnitsy greenhouse, you will need to cut six blanks from a 20x20 mm profile, 300 mm long. Corner posts (4 pcs.) Are cut out by 300 mm from a profile pipe 40x20 mm.

First of all, you will need to weld two frames 140x210 mm in size from a 40x20 mm profile. The scheme is this - first, a pair of two segments of 140-210 cm is welded at a right angle. You need to cook on a flat base, strictly maintaining the angle.

Then two letters "G" are laid out on boards, fixed with clamps and welded into a rectangular frame. Welding seams will need to be beaten off with a hammer to remove slag, scale, metal drops. To make the base of the Khlebnitsy greenhouse, two such frames will need to be made.

Next, we remove one of the frames, and vertically 30 cm segments are welded to the second according to the drawing. In the corners - from a profile of 40x20 mm, so that the frame of the greenhouse is more or less stable. The rest of the racks are from a profile of 20x20 mm or 15x15 mm. Strength and stability for the greenhouse - "Khlebnitsa" is enough even at 10x15 mm.

Each part is pre-tacked with one point, then aligned with a square in two perpendicular vertical planes. Only then can a full seam be made.

Once all the uprights have been welded on, the second rectangular frame can be laid on top. It must be fixed with clamps in the corners on the racks, if necessary, bend them so that the dimensions match completely.

Important! Racks are welded between the upper and lower frame, and not on top or from the inside.

Further, the details of the "Khlebnitsa" are welded, first at the corners, then the rest of the racks are welded.

Assembling the swivel assembly and mounting the sashes

Now you need to install the rotary "roof" of the greenhouse on its base. For the first time, the wings of the "Khlebnitsa" are laid out on the base for fitting. You need to choose the places where the hinge plates will be installed.

At the same time, you will need to mark the holes for the bolts with the nut. They will perform the functions of rotary axes. After marking, the place for installing the plates is determined. Along the line, you need to make a cut with a grinder.

Since the plate is quite thick, the cut must be made twice so that the hole width is at least 6 mm.

The same cut must be made on the reverse side of the profile. Next, you need to cut four plates 5x3 cm from steel 5-6 mm thick. In the upper part it is necessary to drill holes for the axles.

The same holes are drilled in the corners of the Khlebnitsy greenhouse doors.

After drilling, all plate parts and both wings are laid out on the base of the greenhouse, a bolt is threaded into the holes. This must be done on both sides of the "Khlebnitsa". Until the plates are welded to the upper profile, you need to open and close the doors a couple of times, make sure that nothing interferes with the movement of the halves of the greenhouse.

If there are no comments on turning the valves, then the plates can be welded to the base of the "Khlebnitsa".

It is clear that after welding, the seam must be cleaned of scale, slag, be sure to open it with a primer with a rust converter. Of all the details of the frame of the Khlebnitsy greenhouse, this assembly breaks most often.

If, according to the greenhouse project, it is planned to constantly open and close the doors of the “Khlebnitsa”, then instead of a bolt with a nut, install a hardened steel axle with a diameter of 6 mm. The wear of the surface of a “raw”, soft bolt is an order of magnitude higher than that of hardened steel.

Healthy: Do-it-yourself greenhouse heating system

Installation of the frame of the greenhouse "Khlebnitsy"

The greenhouse will be convenient to use if you install it not on the ground or on a pallet, but raise it higher. So that any person, without much bending down, could open and close the sash of the “Khlebnitsa”.

The easiest way is to put the frame of the greenhouse on its side and weld one reinforcing bar with a diameter of 10-12 mm to the corner vertical posts. When installed, the rods will penetrate deeply (10 cm) into soft soil, thereby ensuring reliable fixation of the Khlebnitsy greenhouse on the site.

After attaching the racks, the greenhouse will need to be disassembled. Clean all metal surfaces with sandpaper (to white metal), then wipe first with a dry rag, then clean, soaked in a solvent, for example, in P647.

Since it is planned to grow seedlings inside the Khlebnitsa, heat and high air humidity will eventually lead to intense rusting of the metal. Therefore, it is desirable to pre-prime and dry all the metal parts of the greenhouse, only then it will be possible to paint in any color, not necessarily green.

We sheathe the frame with polycarbonate

If you look closely at the structure of cellular polycarbonate, you can see that it consists of two layers separated by partitions. At the same time, the cloth is quite soft, it can be bent in an arc. Moreover, according to the instructions, polycarbonate on rounded surfaces must be laid with “ribs” parallel to the arcs.

Otherwise, over time, the lining will lose its initial tension and sag like a plastic film in the wind. More detailed recommendations should be viewed depending on the brand of material.

On all other surfaces of the "Khlebnitsa" of the greenhouse, polycarbonate is mounted so that the ribs are located vertically. This is done intentionally in order to allow the water condensate that falls inside the honeycombs to freely flow down the walls.

The upper edge of the polycarbonate must be closed. For roofing roofs, canopies or peaks, special end strips are used. For a simple greenhouse "Khlebnitsy" it is enough to seal the upper edge of the canvas with ordinary tape.

Since the frame of the greenhouse is assembled from a steel profile pipe, it is necessary to fix the cellular polycarbonate use special self-tapping drills with a hexagonal head, a wide metal washer and silicone gasket.

It is impossible to fasten polycarbonate with ordinary metal screws or bolts and nuts. Carbonate has a very high coefficient of thermal expansion. If the material is heated by sunlight, then its length may increase by 2-3 mm. Accordingly, the lining on the Khlebnitsa greenhouse in the heat can swell with bubbles, and in the night cold it can stretch, up to damage and rupture of the canvas.

Therefore, it is necessary to fix polycarbonate on the frame of the greenhouse in the following order:

- Pieces of the required size are cut out of a 6 meter canvas.

- Carbonate blanks are laid out on the frame and fixed with tape. It is advisable to disassemble the bread box in advance, it is more convenient to work with self-tapping screws.

- Mark points for screwing fasteners into the metal profile.

- A hole with a diameter of 2.5 mm is drilled at the points for a self-tapping screw, at the same time a hole equal to the diameter of the fastener plus 1.1-1.5 mm is knocked out with a special punching tool.

- Fasteners are inserted into the prepared hole and wrapped until the silicone washer contacts the polycarbonate surface.

The carbonate should be only slightly pressed against the pipe, you can even check it with your hand, but most often visual control is enough. The silicone washer reliably protects the hole in the cladding from water ingress, and the gap between the self-tapping screw and the canvas allows the latter to expand freely during heating or cooling.

Results

Building a greenhouse "Khlebnitsa" with your own hands is no more difficult than an ordinary greenhouse or a greenhouse on a wooden frame. All that is required is to precisely assemble the swivel assembly so that the sashes do not cling to the edges when opening and closing. And it is also necessary to properly cut and fix the polycarbonate on the metal frame of the building.

Tell us about your experience in building the Khlebnitsy greenhouse. What problem areas do you think should be addressed first? Also save the article to bookmarks and share it on social networks.