Fastening the log to the concrete floor is usually carried out using reliable self-tapping screws or anchors. The latter option is more reliable, although corners and racks with automatic correction are also used along with it. Step-by-step instructions in different cases, practical advice from experienced craftsmen can be found in this article.

The content of the article

- What lags are suitable

-

Mounting technology options

- Fastening using self-tapping screws

-

Use of anchors

- Corner fixing

What lags are suitable

Logs are affordable material that is easy enough to install on your own. They provide a uniform load on the floor and save money on installation. Fasteners for floor logs fit well both on a leveled surface and on a floor with defects that can be corrected by building up or filing a beam.

But there is a significant disadvantage associated with the fact that the design can creak. Extraneous sounds appear due to improper installation or as wear due to displacement of parts. Therefore, fasteners for logs on a concrete floor must be very rigid. In addition, it is necessary to take into account several requirements for the material:

- the humidity indicator should be a maximum of 18%, better - even less;

- if the logs are not treated with compounds from decay and for fire safety, this must be done immediately before installation;

- it is better not to fix the lag immediately - they need to be held for several days in the room where the installation is planned.

Installing a lag involves choosing a material of a certain section. It depends on what the step of the beam will be, i.e. distance between adjacent elements.

| Interval, cm | Minimum section, mm |

| 30 | 150*80 |

| 40 | 180*100 |

| 50 | 200*150 |

| 60 | 220*180 |

In order for the fastening for the floor log to be as reliable as possible, the maximum distance between adjacent bars should also be calculated. It directly depends on the thickness of the top coating, for example, plywood.

| Coating thickness, mm | Maximum step, cm |

| 20 | 30 |

| 25 | 40 |

| 30 | 50 |

| 35 | 60 |

| 40 | 70 |

| 45 | 80 |

Mounting technology options

There are several ways to attach logs to a concrete floor. For example, they can be fixed with self-tapping screws or use such a reliable element as an anchor bolt. Step by step instructions with photos look like this.

Fastening using self-tapping screws

The main answer to the question of how to fix the logs to the concrete floor is with self-tapping screws. To do this, it is enough to drill holes for dowels in the concrete floor and wooden beams. The sequence of actions is as follows:

- Preliminary eliminate all defects on the concrete surface. To do this, use mounting foam or mortar.

- Fastening the lag to concrete must be done on a clean surface - dust is first removed from it with a vacuum cleaner.

- Then they pass the floor with a primer solution, in which it is recommended to add an antiseptic.

- Installation of a log on a concrete floor is carried out at intervals of 50 cm or less, depending on their cross section.

- If necessary, plastic wedges are placed under the bars to adjust the height. Constantly check the level readings.

- Regardless of the way how to fix the logs, the principle is the same - you need to make marks and drill holes for self-tapping screws or anchors.

- Next, install a self-tapping screw, screw it in and do the same with the rest of the fasteners.

- The wedges are fixed with mounting tape, as shown by the arrows in the photo.

- Now it's time to lay the insulation in the space between the bars.

- A vapor barrier is laid on top.

- OSB boards are laid and fixed - then comes the finishing.

Use of anchors

There is another way to install logs - for this, anchor bolts are used. Such a fastener is more reliable than self-tapping screws, since it provides maximum structural rigidity.

The way to fix the logs to the concrete floor can be described as follows:

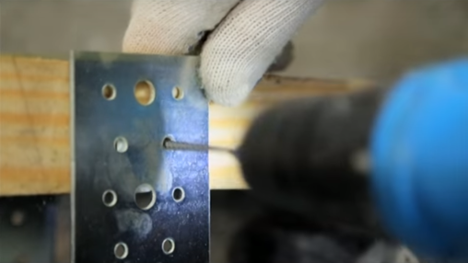

- They make markings, make holes in the beams and the floor surface, and the holes must be sufficient for the hats to “drown” in the wood. Hammer the anchors directly into the concrete using a hammer.

- Working with a 13 wrench, pull each anchor nut in order to tighten it well. But at the same time, you should not make maximum efforts - you can break the thread.

- Before starting the installation of the log, it is necessary to screw the lower nut onto each anchor and put the washer. Moreover, the nut is put on the reverse side.

- From above you need to throw the puck.

- Holes are drilled in the logs, taking into account the diameter of the cap.

- Logs on the corners are installed on anchors.

- Install the anchor head on top for fixation.

- The nuts are tightened to a level.

- Excess parts are removed with a grinder.

- Then, as in the previous case, it is necessary to lay the insulation and carry out the finishing.

Corner fixing

There is no doubt whether it is necessary to fix the logs to the concrete floor. But this can be done in different ways, for example, using metal corners. The main steps are:

- Before attaching the corners to the lags, holes are drilled for self-tapping screws. Moreover, the fasteners must be immersed in the wood as deeply as possible.

- Holes for dowels must be drilled in the surface of the concrete floor.

- Dowels are placed in holes and screws are screwed in.

- Now you need to decide what to put under the logs on the concrete floor. It is recommended to put bars under them. Thanks to this, there is enough space, and air circulation is unhindered.

- The bars are fixed using metal corners.

- Lay wooden flooring from grooved boards.

- To strengthen the board at an angle, make holes for self-tapping screws.

- The boards are fixed with self-tapping screws - they are placed in the grooves, observing an angle of 45o.

Today on the market you can find adjustable beams with special racks. They are installed on a flat surface, and then the optimal height is determined by the level. Such supports automatically adjust the level of inclination within 5 degrees.

However, it is not necessary to purchase self-adjusting racks. In any case, you will need to pre-prepare the surface - if it is not even, the differences will become noticeable. Often, in practice, they use the option of fastening with anchors, because thanks to this, the structure will become as rigid as possible. And even after several years of active load, the floor will not creak while walking.