The use of cladding for the walls of the house has long become a standard. Moreover, for most modern wall materials, such as aerated concrete or foam concrete, laying with facing bricks has become almost mandatory. This is one of the most difficult and at the same time effective ways to make a house truly beautiful and durable.

The content of the article:

-

We prepare tools and materials

- Special fixtures for masonry

-

brick cladding technology

- Preparing the foundation

- How to prepare the first row

- How to check the geometry of the future first row

- Solution preparation

- Putting the bottom row

- Laying the corners

- Wall covering

- Attaching the cladding to the wall

- Lay slopes

- Stitching

We prepare tools and materials

For laying facing bricks, the same set of fixtures, tools and auxiliary equipment is used as for draft bricks.

Standard set of tools:

- Trowel (trowel).

- Wooden square with a right angle and legs of 50-70 cm. Used to check the corners after laying the facing stone.

- Construction hammer with a hardened chisel for chipping (beating) bricks in size.

- Stitching for seams. A curved steel cylinder (sector) on the handle is needed to give the seams the desired profile.

- Building level.

- Scoop-measure. Used to take masonry mortar out of a bucket. With it, you can always collect the same amount of masonry mixture.

- Tension cords or mooring.

- Plumb and rule. The first is a weight, usually on a fishing line or a thin nylon thread (non-stretchable). The second is a bar, wooden or aluminum, it doesn’t matter, the main thing is smooth. With its help, the plane of the wall is checked.

To knead the masonry mixture, you will need a convenient container for carrying the solution, in extreme cases, a bucket with low and wide sides, a shovel and a concrete mixer with a trough. Even for laying facing bricks, dispensers (cuvettes) can be used.

4-5 kg of masonry mortar is loaded into the bunker, after which the dispenser passes along the wall, leaving behind a layer of the required thickness. The assistant lays out the facing brick, and the master levels the material with his own hands, upsetting it if necessary. The cladding process is accelerated, but the method is not suitable for all types of facing ceramic bricks.

The cuvette method of applying the solution is mainly used for wall stones and baked clay blocks.

Special fixtures for masonry

The main difficulty in laying facing bricks is to lay the stone in a row as accurately as possible. Maintain the plane of the wall, the ledge, the width of the vertical and horizontal joints.

Therefore, masons massively use additional equipment, for example, trihedral corners. A pair of metal corners are mounted on the corners, mooring cords (like painting ones) are stretched between them. The cord ensures the accuracy of laying facing bricks.

Another option is corners-orders. They are also fastened in pairs vertically at the corners of the box, and cords are pulled between them. Unlike simple trihedrons, the slats have cuts with a pitch of 77 mm. That is, by rearranging the cord, you can simplify the control of the thickness of the seam between the rows. Although the horizon, ledge and plane still have to be controlled after each laid facing brick.

For accelerated masonry, so-called installation templates are also used. In fact, this is a massive frame made of durable plastic. Thanks to it, it is possible to accurately maintain the width of the seams, without a “blockage” of the plane or the formation of an external protrusion. All that is required is to apply masonry mortar and lay the facing brick inside the frame, as in the video.

Most bricklayers prefer to use simpler tools to control the quality of masonry. The standard set of the master usually includes several bars (usually aluminum or steel) with a diameter of 8 mm or 10 mm, 15 mm, 40 mm and 60 mm long. They are used to check the seam, as well as when laying facing bricks in the first row of masonry.

But the building level, trowel and hammer (pick) of a bricklayer are considered truly indispensable.

brick cladding technology

There are 2 important points in laying with facing material:

- It is possible to lay facing only on the prepared basis. Usually this is the basement of the walls, lined with ordinary brick for tile, siding or plaster.

- In order for the rows of facing bricks to turn out to be even, first of all, the corners of the building are laid out. Before moving on to the main laying of the rows, each corner is laid out on 4-5 single bricks.

3-4 rows of facing stone are laid out on one wall, after which they move to the opposite side. The laid out area should dry with a slight shrinkage. This is done so that new rows of facing bricks do not deform the previously completed masonry.

Preparing the foundation

As a rule, facing bricks are laid on top of the walls of an already built house box. What the inner masonry is made of, so far does not really matter. The main thing is the basement of the building. Places on a ledge made of concrete or rubble should be enough for laying ½ facing bricks. Usually there is a gap of 5-7 cm between the outer cladding and the old wall.

If the plinth is made of rubble stone, and no additional finishing is expected, then the facing brick is laid out flush with the vertical surface of the rubble masonry. If the plinth is concrete, the place for the first row of facing masonry is chosen so that the brick is laid with a release of 2-2.5 cm. The same technology is used if the laying of the main material of the walls and cladding is carried out simultaneously.

Another nuance is that facing bricks are laid on a waterproofing layer. Usually this is a double-folded glass roofing material. To prepare, you need to lift (raise the edge) of the roofing material to gain access to the concrete. The area under the waterproofing is protected with a chisel and a grinder from protruding "cones", "humps" so that the surface is even. After staining with mastic and bend the edge of the glass roofing material into place.

How to prepare the first row

The next step is the preparation of the brick. The facing stone is usually of high quality, but for the first row you need to choose a material with ideal geometry. For one wall of the facade with a width of 10-11 m, approximately 40-45 pieces will be required.

Next, you need to lay out the first lower row of facing stone on the base in a dry way, that is, without mortar. This is necessary to accurately calculate the number of bricks.

The material must be laid out sequentially in a chain, controlling the gap (vertical seam) with the help of a template. At this stage, there is always a problem with an incomplete series. It is rare when an integer number of bricks is placed in the first row. Usually there is an unfilled gap, the dimensions of which can be from ½ to a whole (often ¾ of the normal length) brick, or a very small piece, from ½ to ¼ size.

For ordinary red ordinary brick, it is considered normal to cut or chip off a piece (half or quarter) to fill an empty gap in the masonry. In the case of a facing stone, this cannot be done, since in the masonry it is necessary to maintain a symmetrical arrangement of all vertical seams. Otherwise it will be ugly.

How to properly fit the dimensions of the first row of brickwork

If the size of the empty gap is less than ¼ of the length, then the "hole" in the row can be compensated for by increasing the width of the seam. For example, for a gap of 60-70 mm and with 40 bricks in a row, the increase in the gap will be 5-7%. It will be invisible to the eye. That is, on a problematic wall, you just need to increase the vertical seam between the facing bricks.

A more difficult situation is if the gap in the row is ¾ of the length. In this case, it will be necessary to shorten several bricks (5-6 pieces) in the middle of the row with a grinder by 10-20 mm. This also helps mask the problem in the masonry.

But you need to cut all the facing bricks in this area of \u200b\u200bmasonry until the wall reaches the design height. The required amount of facing bricks can be cut in advance, or this can be done during the laying of the front wall. Cut blanks on a desktop machine with a diamond disc.

How to check the geometry of the future first row

When laying out the bottom row, it is important not only to calculate the amount of material, to adjust the gaps (vertical seams). It is also necessary to align and correctly plan the geometry of the future box of facing bricks.

After the first (lower) row has been laid out dry, mooring cords (mooring) must be pulled on all four sides. The line should run along the very edge of the brick. To fix the mooring, 2 thick reinforcing bars are driven in at each corner of the basement of the building's foundation. It turns out a square or rectangular contour, girded with one piece of fishing line (mooring).

The cord is pulled through both rods so that a right triangle is formed at the corner. In three corners, the size of the legs is 50-60 cm. In the most problematic corner, the rods are carried to a distance of up to 150 cm. This is necessary in order to get 90o on all four corners of the future box.

On an open foundation, this procedure is carried out by adjusting the lengths of the diagonals. But if the building box is already standing, then this method is not available. Therefore, the alignment of angles in 90O performed using one of the corner triangles with legs 150 cm.

The rule says that the angle will be right if one leg is equal to 4 measures (120 cm), the other is 3 (90 cm), and the hypotenuse is 5 (150 cm). You have to adjust the position of the mooring until you get a triangle of the desired proportions.

It is imperative to align the corners on the first row of facing bricks, otherwise, after the completion of the laying of the walls, the box of the house will turn out to be crooked, and this will be clearly visible to the naked eye.

Solution preparation

The easiest way is to buy a ready-made mixture based on sand and cement. Some companies producing building materials so directly indicate on the packaging - a mixture for laying facing bricks.

The first thing you need to pay attention to is the brand of the solution. For cement-sand mixtures, it can be from M25 to M150. For laying the facing material, a mixture of brand M50 is used. It can also be used to repair the plinth before laying out the first row.

Perhaps for the first experience of face bricklaying, this is a good solution, provided that the mixture is of really high quality. But for a full-fledged cladding of the walls of a house or building a box, buying a ready-made mixture will be too expensive a decision. Therefore, the masonry mixture must be prepared independently.

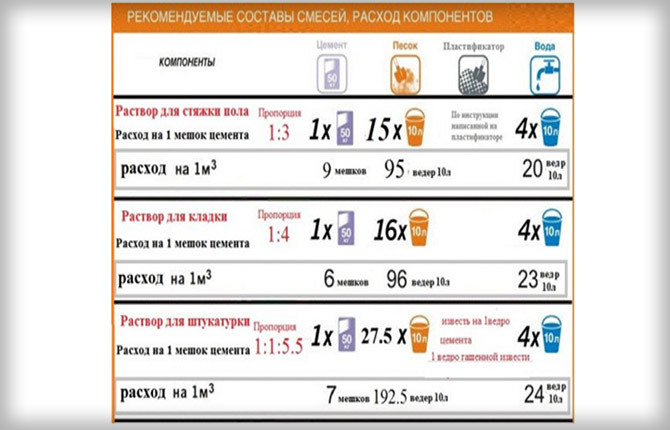

The composition of the masonry mixture for facing bricks:

- Cement M300-M400, 1 bag weighing 50 kg.

- Sand washed, river, large grain - 16 ten-liter buckets.

- Clean water, tap or rain, 40 l.

The result is 230 liters of masonry mixture. If counted for one cube of mortar, then 6-7 bags of cement, 96 liters of sand and 230 liters of water will be required. For walls half a brick thick, the consumption of masonry mixture is from 100 liters to 160 liters of mortar per meter of masonry area. If we consider the area of the wall of facing bricks (thickness ½ stone), then the required consumption will be 35 l / m2.

For the first row of facing bricks, the consumption will be at the level of 40-45 l / m2 walls.

It is better not to add various kinds of modifiers or additives to the batch if there is no stable practice of their use. It is better to immediately refuse lime, liquid soap, various detergents. The facing brick is made by semi-dry pressing, therefore, after firing, the clay turns out to be highly porous, like a sponge, and absorbs and “pulls out” all water-soluble additives from the solution. As a result, white and yellow spots form on the surface of the brick, which are not easy to remove.

Now you need to properly prepare the batch. If there is no concrete mixer, then use a large, 50-100 l, trough. Sand and cement are first loaded in small portions, everything is mixed with a shovel in a dry form. Then pour 50% water and moisten the mixture for complete wetting.

The rest of the liquid is added in small portions and constantly stirred. The brick mortar will seem liquid at first, but after 20-25 minutes the viscosity will increase. At this point, water should be added to obtain the desired consistency.

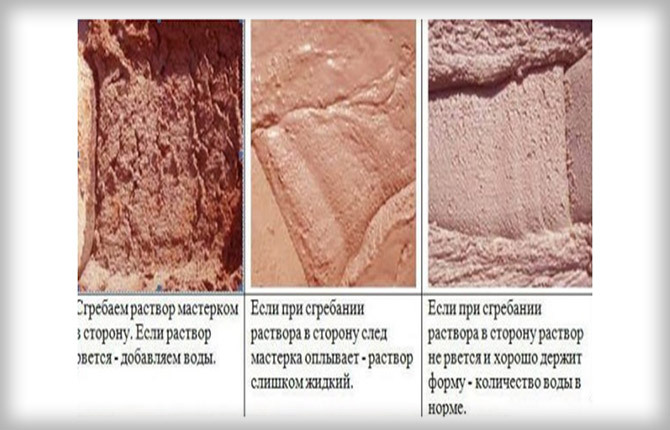

The quality of the solution is checked by how the trace from the trowel in the trough blurs. If the mixture floats, then you need to add a little dry grout (thoroughly dry sand and cement), wait and test again with a trowel. Or add water.

A good quality mortar lays down on the facing brick, like cream on a cake. It is plastic, but does not blur, keeps on the voids and does not fall into the holes.

Putting the bottom row

The first row is the most difficult to install. Even if the facing brick was laid out beforehand, adjusted in length so that the vertical seams look absolutely symmetrical.

The bottom row is laid on waterproofing, under which there is a rather uneven surface of the concrete base. In addition, the first row is usually laid out with a release of 2-2.5 cm, that is, part of the material hangs over the vertical plane of the base.

Therefore, under each brick, you have to lay a little more mortar, stretch the mixture into a strip up to 60 cm long, let it grab a little before laying the cladding. Spread 2-3 stones at once, without embedding the mixture in vertical seams. Burnt clay absorbs water, so you need to quickly level the masonry horizontally, knocking out the material with a trowel handle. And they immediately check the horizon, but already in the direction transverse to the row.

While the material has not rigidly sat down on the mortar and still retains mobility, it is necessary to align the gaps on the vertical seams with a rod (caliber) and fill them with mortar. Upon completion of the calculation of the first row, at least a day must pass before work can be continued.

During this time, you need to prepare tie-ins and transitions near the doorway, porch, fittings (faucets and pipes) protruding from the walls of the house.

Laying the corners

The quality of the laying of the entire cladding of the house depends on how correctly the corner zones are laid out with facing bricks. In order to control how accurately the brick lays down, you need to prepare a bench or flooring, standing on which you can see the masonry from above and from the sides.

First of all, template rods are laid out at the corner - they help not only to withstand the thickness of the horizontal seam, but also to level the brick without a mooring cord.

Next, a solution is applied to the corner, and immediately under 2 adjacent bricks. The amount of the mixture is slightly more than when laying a full-bodied stone. The excess will be squeezed into the voids, so there will be no overdose.

After leveling the layer, 2 steel wire staples are immediately laid to securely tie the corner to the masonry walls. In this case, this is a necessary measure, since under the previous row, instead of a whole stone, two halves are laid, and even lower - 2 whole bricks. That is, 3 vertical seams lined up in one line without dressing.

The next step is to lay out the corner bricks on the mortar so that the lower vertical seams are bound.

The laid material is upset by blows of the trowel handle, first along the upper plane, then along the outer side. At the same time, it is necessary to control the position of the facing, looking from above, so that the outer edge of the stone is exactly opposite the metal rod.

Now you need to lay the second mating stone. A small amount of solution is applied to the end and laid out in a row. The second facing brick of the corner must be immediately laid in size, without horizontal padding. Otherwise, by hitting the outer end of the stone, you can easily “knock out” the first brick from its place. He will move a couple of millimeters, this may not be noticed.

If you continue laying with padding, then as the number of rows increases, the corner of the facing brick will fall outward. The seams in the corners will increase, and after completion of the work, the corner zone will become a curve.

Therefore, the second brick is laid, first touching the mortar with the far edge of the poke, and then, as if rolling, rest against the end (with the smeared mortar) against the side of the first. He may not sit on the masonry mixture completely, so you need to lightly tap the trowel handle along the seam, as in the photo. This is the most difficult stage of laying the corner.

If it is not possible to correctly lay the second brick without tamping, then you need to change the masonry pattern. Lay the stone on a row without first spreading the mortar on the end. With one hand, the facing brick is lowered onto the mortar, with the second they hold the template so as not to “crush” the joint.

After a slight draft (by blows of the trowel), the material will reliably “stick” to the row, and it is possible to seal the empty seam with masonry mixture. This is done simply. A small amount of the mixture is picked up on the trowel, pounced on the seam and fill the space with chopping movements.

Now you need to check the horizon of both bricks at once, at the same time control the vertical deviation of the facing material relative to the wall.

In this way, laying another 2-3 layers of the corner should be done, always with dressing of the seams. Then move on to the next corner area. Once the two corners of the box are laid out, you can move on to laying the wall between them.

Wall covering

As a rule, wall masonry with facing bricks is easier than corner masonry. All that is needed is to withstand the thickness of the joints and constantly monitor the position of the brick in the row.

First of all, for a new row, a mooring is pulled between the corners, for this a couple of nails are inserted and the paint cord is stretched. For long distances (5-10 m) it is more convenient than fishing line, as it does not sag and is not blown out by the wind.

Next, you need to set the bar template. It is laid out on the edge of the bottom row so that it does not protrude beyond the outer surface of the wall.

Now you need to determine which stone to start laying with. If there is a whole stone on the bottom row in this place, then the new one should be continued with a half. For styling, apply a solution, a little mixture on the end of the halves, and you can put it in place.

It is better to smear the excess and remove the remnants. Otherwise, the excess will come out of the seam and harden on the facing brick with a huge bump or, even worse, blur in a blot. If the mortar is of good quality (and the other is not suitable for facing bricks), then it may take several days to clean up its residues.

The scheme for laying facing bricks in a row is somewhat different from how it was done in a corner. You should try not to put a half, but stick it diagonally, pressing the stone simultaneously in vertical and horizontal directions. After laying, the facing brick is knocked out in the area of the seam, at the end and along the upper plane.

The position of the brick is checked using the building level, the horizontal direction is controlled and the vertical direction along the outer wall.

How to check the absence of "blockage" of the stone? The level is laid across the surface of the newly laid brick, pressed with fingers and knocked out with a hammer until the device shows the desired position of the bubble.

Similarly, the longitudinal slope is checked, but already on several bricks at once.

Before laying the next stone, the bar is moved along the row.

Usually, the presence of a half in the cladding is an exceptional situation. An incomplete brick in a row drastically worsens the appearance of the cladding. Therefore, the halves are placed at the corners, in the slopes of doors and windows, in complex structures where there is no other way to untie the row.

How to properly cut a facing brick - according to technology, this must be done using a grinder and a diamond wheel. But these are cases where you need to cut very accurately. During the laying process, the cladding is split in half.

For this you need:

- Choose a prick line (it is not necessary to prick in the middle).

- Hit with a chisel of a construction hammer along the line on one front face and exactly the same with the opposite.

- Hit a line on the supporting surface.

As a rule, the material splits along the line of voids. Some craftsmen pre-knock out the lintels inside with a hammer, and only then split the facing brick.

Attaching the cladding to the wall

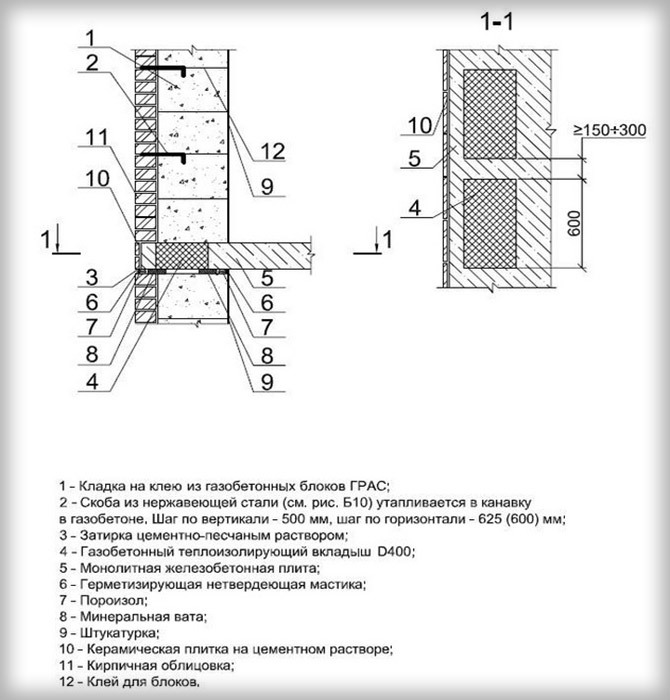

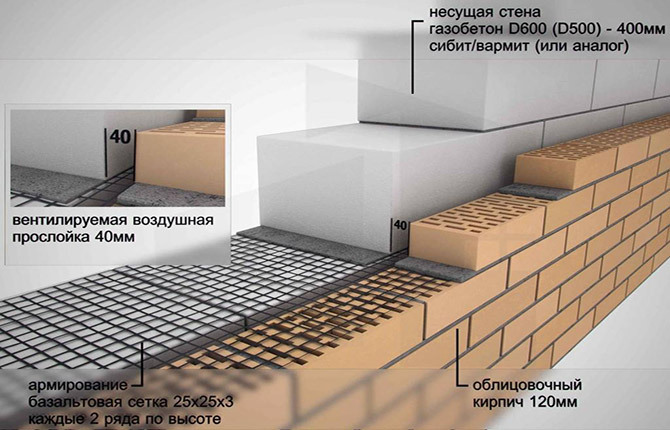

Half-brick laying is unstable. Therefore, the front wall is tied to the main box of the building. The binding scheme depends on the type of material from which the house itself is built.

For example, dowels with wound wire can be used to fasten facing bricks to old brickwork. The ends are bred to the sides and sealed into a masonry seam.

If the cladding is done with clinker, then the front wall is attached to the old brick wall using conventional galvanized tape hangers.

A little more difficult is the binding of the cladding to the walls of aerated concrete or foam block. The best option is to embed stainless steel brackets into aerated concrete blocks. Horizontal pitch 600 mm, vertical pitch 500 mm. In the future, when laying the facing brick, the staples are embedded in the inter-row seams.

Sometimes a box of aerated concrete is erected simultaneously with the facing wall. In this case, the dressing is performed using steel reinforcing meshes.

Lay slopes

You can decorate door and window openings, turns or figured columns of the front wall using facing bricks of a special configuration. Such a stone has ready-made bevels, curly protrusions. It is only necessary to lay out the facing brick in the window opening.

Slopes can be formed from halves of facing bricks, but of a different color. For example, lay out the lower level (under the windowsill).

Vertical surfaces are also laid out from halves, but already with staples tied to the main lining.

The upper level - the overlap of the window opening - is laid out on a metal corner.

Stitching

This is a procedure for cleaning and adjusting inter-row seams using a special tool - jointing. Immediately after laying out the first 10 rows, the seams are cleaned from the remnants of the solution and a special profile is formed. Such running-in improves the appearance of facing masonry.

Facing brick laying is a complex and time-consuming procedure that requires experience and skills in working with various types of cladding. But a little experience can be gained in the design of porches, the entrance group of the house, doorways. Professional work with facing is possible only after 2-3 years of practice as a bricklayer.

Tell us about your experience with laying cladding - what features of laying should you pay special attention to?