Pile foundation - a supporting structure of several columnar elements driven into the ground and connected to each other. It is used for the construction of residential and frame buildings and small industrial facilities on unsteady soil.

The content of the article:

- What is a pile foundation

- Device

- Calculating height above ground

- How to calculate diving depth

- Step-by-step DIY installation instructions

- Scheme for creating a bored base

- Grillage technology

What is a pile foundation

The supporting structure is designed and erected using piles, which take the load of the underground or above-ground part of the building and transfer it to the denser lower layers of soil. This is a shallow construction without improvement measures soil. The type of foundation is determined at the construction stage of the project, taking into account the type of relief, the depth of water, and the weight of the future building.

Unstable weak soils are usually located near forests, in places of high humidity. Fluid clay, sandy, watery soil are indicators for the construction of a pile foundation. such a system has a number of advantages:

- arrangement in a problem area;

- does not require labor-intensive excavation work;

- relatively quick installation;

- the design does not shrink;

- the weight of the structure is evenly distributed on the supports;

- work does not depend on the time of year.

Allows you to reduce costs devices underground part of the building. In the future, a later built extension can be attached to the pile foundation.

Disadvantages of a pile foundation — impossibility of construction on a rocky surface. To determine the depth of laying pipes, an accurate calculation is required. The metal structure requires anti-corrosion protection. The construction of heavy high-rise buildings and bridges requires a deep foundation. Installation Such structures are complex, using special equipment.

We read: How to make a columnar foundation with your own hands

Device

The main point when constructing a building on soft soil is the arrangement of a pile foundation. The structure is made up of submersible piles, grillage and strappings. Pillars and pipe rods are strong supports embedded in the earth mass. Their upper part, the head, is embedded in a grillage, the lower part, the sole, is sunk into a dense layer.

Grillage— a monolithic concrete lattice on which the walls are installed. It can be reinforced concrete, metal or wood. It is located along the perimeter of the building, under the external load-bearing walls. Harness - this is an element that unites scatteredly located piles into a single system. It ensures the stability of the pile pillars and evenly distributes the mass of the building onto the ground.

Grillageless pile foundations - single support beams, using caps, nozzles, monolithic glasses. Structures with a grillage are installed under columns or load-bearing walls that include more than two supports. These are single or double row tape grillages.

Reinforced concrete is usually used to make piles. They can be steel, rarely wooden. Possible use concrete or rubble concrete, which somewhat reduces the price of the structure. To increase strength, the pile foundation is reinforced. The reinforcement is made of profiled or smooth steel rods.

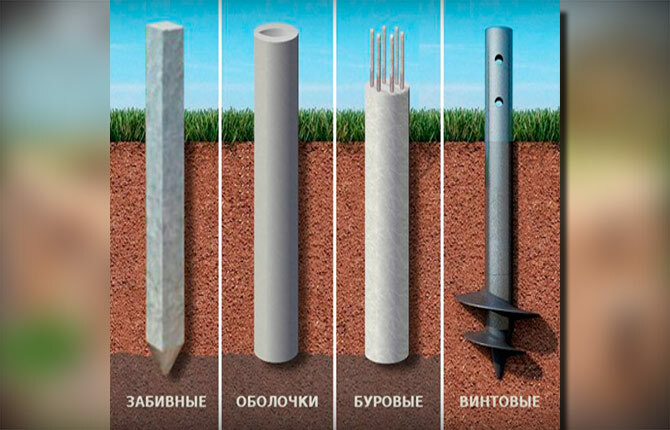

By method installations pile foundation pillars are of the following types.

- Drive-in - ready-made reinforced concrete supports with reinforcement. Metal ones are used less frequently.

- Pressed or bored ones are made at the construction site. Pre-drilled and filled with framing reinforcement wells poured with concrete. This method is preferable, especially for individual developers, since transportation and loading and unloading are not required work.

- Screw metal ones are inserted into the ground like a screw, manually or using a mechanism. The advantage of this method is the absence of excavation work. Their use on relief terrain is especially justified. But they are more susceptible to corrosion.

- Bored screws are ready-made reinforced concrete piles at the end with a screw that are screwed into the ground.

- Hanging - do not rest on solid ground. They are supported by weight due to the frictional force of the side walls. They are used when the dense layer is too deep.

Depending on the installation site, piles are either mandatory or intermediate. The first are located in the corners of the house, at the intersection of external and load-bearing walls. If the distance between the required ones is 2.5 meters or more, intermediate supports are added.

A pile foundation may consist of separately located piles. The cluster method involves placing a certain number of elements in a triangle, square, square with a central support.

The tape method is placement in one or two lines, and the distance between the supports is equal to three of its transverse diameters. For a “continuous field” the gap between adjacent supports is 3–6 diameters.

Calculating height above ground

To make a pile foundation By all rights, some important parameters need to be discussed and selected at the design stage. This is the area of the sole, on which the width of the pile foundation, as well as its height, depends. The most acceptable size of the base part is 300–600 mm. If the house has an underground floor, the height can reach two meters. Pile rods are installed fully or partially recessed into the ground. Place strictly perpendicular to the soil or at an angle.

To determine the size of the base, you need to consider the following points:

- temperature outside in winter and planned inside the house;

- the depth to which the soil freezes;

- soil resistance coefficient;

- estimated snow level;

- risk of building flooding;

- groundwater level;

- bearing capacity of pile foundation elements.

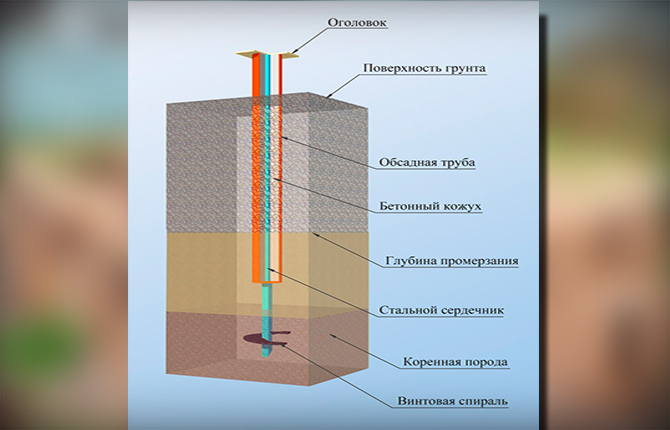

Standard screw piles have a diameter of 100–300 mm and a length of 2500 mm. To keep the walls safe and dry, the height of the plinth should be at least 200–250 mm. This size will make it possible to perform all welding work efficiently. The remaining part of the support above the ground is no more than 850 mm, especially with a diameter of 108 mm. Otherwise, the resulting structure will be unstable and may wobble in strong winds.

Therefore, the most acceptable size of a pile foundation above the ground is 450–550 mm. In this case, the building will be able to stand securely in its place without being exposed to winds. When installing the foundation of a building on a steep slope, it is difficult to comply with all conditions. However, the top of the pile posts must be in line.

There is a special hydraulic level device for checking. It works like communicating vessels. These are two containers of water connected by a hose. For winter you need non-freezing liquid. In a laser level, a guide beam aligns all supports in height. The most accurate and convenient device is a level: digital, optical or laser.

How to calculate diving depth

Placement of piles according to the rules- this is the strength and stability, reliability and durability of the structure. To complete this task, you need to consider the following points:

- type of building;

- seismic activity;

- the magnitude of the load on the pile foundation;

- soil features;

- freezing depth;

- groundwater level.

The degree of driving of pile pillars is determined in accordance with the technical conditions for the foundation and the properties of the soil. So the pile shoe is deepened 50–100 cm into the hard layer of soil. Then the building will not deform and sag and will give minimal settlement. To determine the characteristics and spatial position of strong rocks, geotechnical studies are performed.

According to the rules, piles should be installed 20–25 cm below soil freezing. If average depth freezing in this area is 1.2 meters, the pile foundation must be laid to a depth of 1.5 meters. To determine the depth of immersion under light buildings, a superficial diagnosis is sufficient. To do this, they drill a well up to 2 meters on their own. Evaluate the composition and moisture of the soil. If a dense layer of sand or clay begins at a depth of half a meter, a two-meter pile pipe is needed.

- The depth of driving a reinforced concrete support under a frame house is from 3 to 10 meters, taking into account the composition of the soil. In this case, the cross-sectional size is 150–250 mm.

- In areas with high seismic activity, a immersion of 4 meters is required.

- On water-saturated sands - 8 m.

- When the soil freezes to more than 1.5 m, the piles are driven 2–3 m deep.

- For rammed drilling, drilling is carried out to a depth of 10 to 30 m.

As for the load on the foundation, it is determined by SNiP and TU. On average, one support must support a weight of at least two tons. With a diameter of 89 mm - 4 tons. This is enough to build a gazebo or veranda, while for construction a one-story private house requires pile rods Ø 108 mm, with a load of up to 7 tons.

If it is not possibleto determine the exact characteristics of the soil, the depth of standing water and soil freezing, it is recommended to immerse the pile foundation with a reserve.

Step-by-step DIY installation instructions

In addition to the fact that a pile foundation is used when building a house on the most difficult soils, it is cheaper than a strip or monolithic slab. There is no need to dig a pit, prepare a bed of sand and crushed stone, or lay waterproofing material. The top of the building can be made of wood, brick, foam concrete or sandwich panels. And if make a pile foundation with your own hands, this will significantly reduce the cost of the project.

Building a house on soft soil is not easy. In order for the structure to be reliable, it is important to choose the right supports and carry out installation in compliance with the technology. Preparatory work is carried out in advance:

- test drilling of a well to determine the composition of the soil;

- calculation of immersion depth;

- selection of piles of the required length and diameter;

- planning;

- site marking.

Pile-screw foundation installed in two ways: manual or mechanized.The choice is determined by the availability of free access roads to the construction site, as well as the type of soil, season, and financial support. When a structure needs to be erected quickly, it is worth using a mechanized drilling method. At the same time, if construction is supposed to be carried out in a flooded place or there is no access to it, everything will have to be done manually.

To do this, a lever is inserted into the technological hole of the screw. This could be a metal rod or crowbar. To install screw supports, there is a special tool - a mounting head. By instructions it is put on the screw and secured with a pin. It has two handles and makes work much easier.

Mechanized - this is the use of drilling rigs based on a car chassis, which allows you to drill a pile into the hardest soil. Installation of large diameter pile structures is impossible without auxiliary equipment.

At the last stage, the perpendicularity of the location of the supports is checked. They are cut to the required height. Then cement mortar is poured into the pile supports. It protects the metal from destruction and protects against air penetration. Next, metal caps are welded to them and the construction of the house continues.

Scheme for creating a bored base

Widely used in modern construction technology installation of bored supports. The method is especially relevant within the city, in a limited area, underground, where maximum care is required so as not to damage communications or nearby buildings.

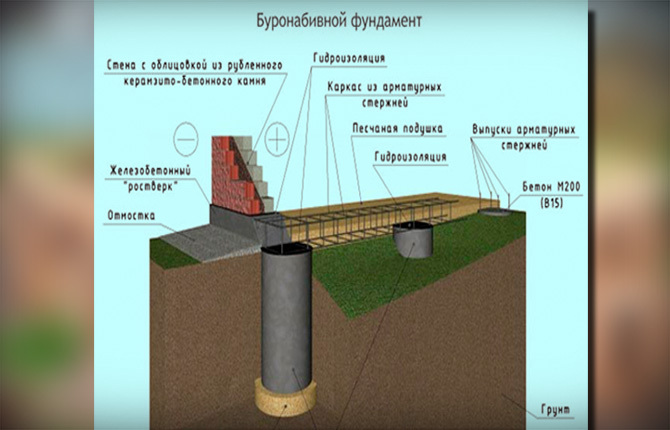

Technology bored foundation consists of two processes: drilling wells and pouring concrete mixture. Before starting work, the load-bearing capacity of the pile and the total load on the foundation are determined. Calculate the required quantity material.

A pile foundation does not require preliminary leveling of the site. Construction may take place in inconvenient areas: hills, slopes, soil folds, therefore preparatory work consists of removing foreign objects and removing the top layer with roots and stems plants.

Then you can stick to the following step by step instructions:

- All installation points piles mark with pegs, maintaining the accuracy and precision of measurements. In these places, small depressions (25–30 cm) are made to make it easier for the drill blades to enter the ground.

- Drilling is carried out to the calculated depth, and if necessary, a “heel” extension is made.

- The inner walls of the well are covered with sections of plastic pipes, roofing felt on a frame made of timber. This is necessary to prevent the earth from collapsing and water leaking out. made of concrete.

- The reinforcement cage is assembled and inserted into the well. The upper part should protrude to a length sufficient to connect to the grillage.

- Pour the concrete mixture. It is bayoneted to remove air bubbles. Complete drying of the structure takes up to a month.

After the concrete hardens, it becomes strong and stable. design. Piles of this type are more often used for the construction of heavy objects. The cost of the work is high, so use it to build a lightweight frame or a wooden house is impractical.

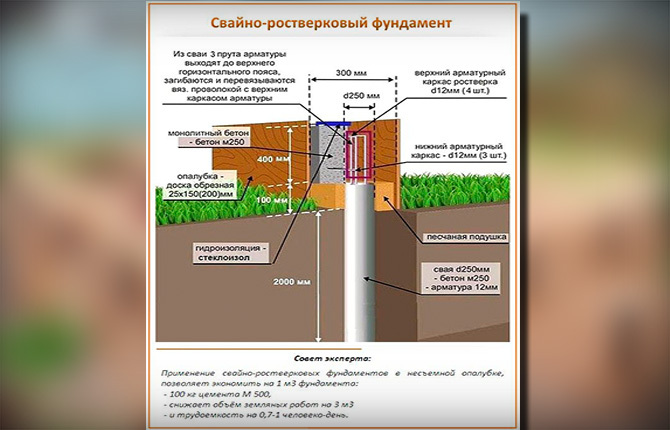

Grillage technology

Construction of pile-grillage foundation is a fairly old and proven method. It is successfully used not only in industrial construction, but also for private cottages. The foundation is laid according to all the rules, to the depth of soil freezing, but at the same time the landscape on the site is preserved.

Disadvantage of the method— the need for accurate calculations and compliance with construction technology (well insulation, use of appropriate fittings). The pile foundation can be made with a hanging and recessed grillage. The first one looks like a structure floating above the ground. The second is buried 20–25 cm into the soil.

The grillage is installed after fills concrete of all pile pillars. First, a form for pouring concrete is set up on the site. Then a reinforcement frame is made. The grillage is concreted in the same way as the piles, bayoneted to remove air. Cover with plastic wrap and leave for four weeks. Formwork removed after 10 days. Construction can continue after the grillage has completely hardened.

A pile foundation is sometimes the only way to firmly attach a structure to a rigid support. In addition to the implementation of construction on difficult soils, it is possible to build a house with your own hands, without the use of heavy equipment.

If you have ever made a pile foundation yourself, tell us about your experience. Leave a comment on the article, share it on social networks, add it to bookmarks.

What kind of house can be built on a pile foundation?

On an ordinary site with dense soil, you can build a two- or even three-story cottage from timber, foam concrete or metal structures. If the site is characterized by excessively soft or loose soil, screw piles will make it easy to erect a one-story building and more.

Is it necessary to make a blind area for a pile foundation?

A pile-screw foundation does not require special protection and the main purpose of the blind area around it is to give a finished appearance to the house and create a convenient pedestrian area. Of course, it also diverts water away from the house, preventing it from flowing into the subfloor, which keeps the metal piles dry and prevents corrosion.